Mixed liquid blending system and blending method

A technology of mixing liquid and mixer, which is applied in mixers, chemical instruments and methods, mixer accessories, etc., can solve the problems of reduced tool life, the mixed liquid does not meet the requirements for use, and the concentration of the mixed liquid is unstable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

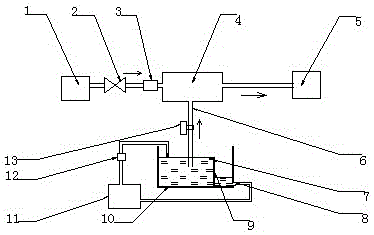

[0036] Adopt the technical scheme disclosed by the invention to deploy the cutting fluid mixture, such as figure 1 As shown, a blending system of a cutting fluid mixture includes a stock solution unit, a diluent unit, a mixer 4 and a central controller. The stock solution unit and the diluent unit are respectively connected to the mixer 4; the stock solution unit is provided with a liquid level sensor 7; A solenoid valve 2 is provided between the diluent unit and the mixer 4; a voltage regulator 3 is provided between the solenoid valve 2 and the mixer 4, and the solenoid valve 2 is electrically connected to the voltage regulator 3; the liquid level sensor 7 is connected to the central control by communication device; the central controller controls and connects the solenoid valve 2.

[0037] The stock solution unit comprises a stock solution pool 11 and a liquid supply pool 10. The stock solution in the stock solution pool 11 flows into the liquid supply pool 10 through a pum...

Embodiment 2

[0052] The rest is the same as that of Embodiment 1, except that the liquid level sensor is arranged on the side wall of the liquid supply tank, and the height of the liquid level sensor is slightly lower than the height of the baffle.

Embodiment 3

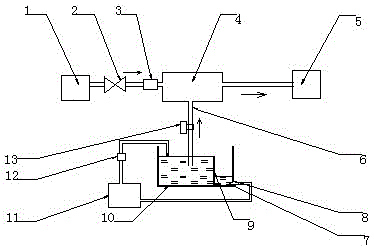

[0054] All the other are identical with embodiment 1, and difference is, as figure 2 As shown, the liquid level sensor is located at the bottom of the overflow port.

[0055] When the raw liquid in the overflow area is cut off, the liquid level sensor cannot detect the liquid level of the raw liquid, and sends a signal to the controller, the controller closes the solenoid valve, and the mixer is closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com