Biomass gasification reaction furnace and automatic control method thereof

A gasification reaction and biomass technology, applied in the direction of electrical program control, fixed bed gasification, program control in sequence/logic controller, etc., can solve the problems of waste of raw materials, inability to produce gas, land occupation and construction cost, etc. , to achieve the effects of reducing labor intensity, promoting full cracking, and reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

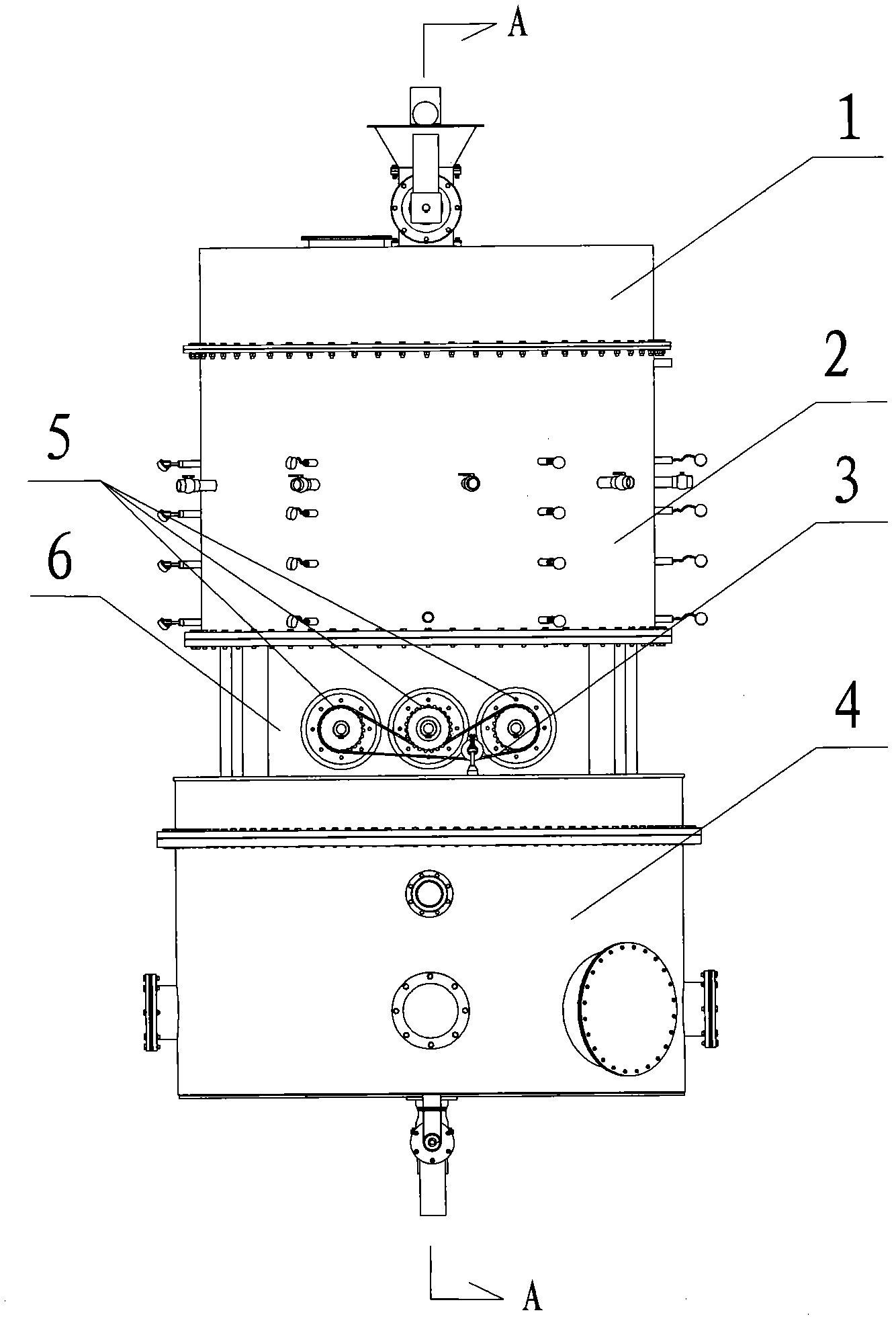

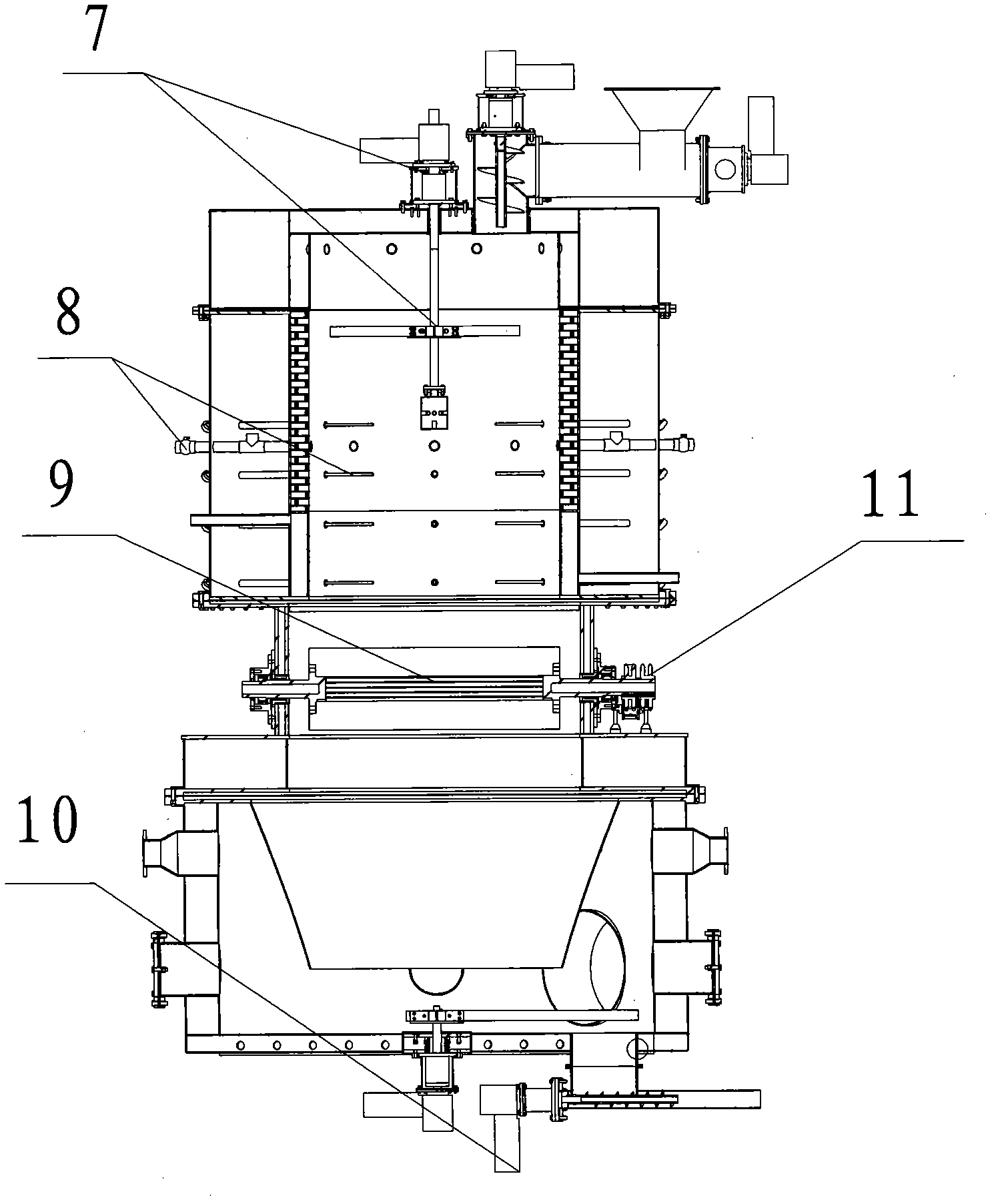

[0039] according to figure 1 and figure 2 As shown, the biomass gasification reaction furnace includes a furnace top 1, a furnace waist 6, a furnace 2, a furnace bottom 4, a fire grate 9, a fire grate rotating transmission device, and a furnace bottom ash discharge sealing device 10, and the fire grate 9 is three Fire grate 9 arranged side by side is formed, and each fire grate 9 is connected with fire grate motor 11 with chain 3 by drive shaft 5 . Furnace top 1 is provided with furnace top stirring air distribution device 7, and furnace 2 is provided with combustion layer air distribution device 8.

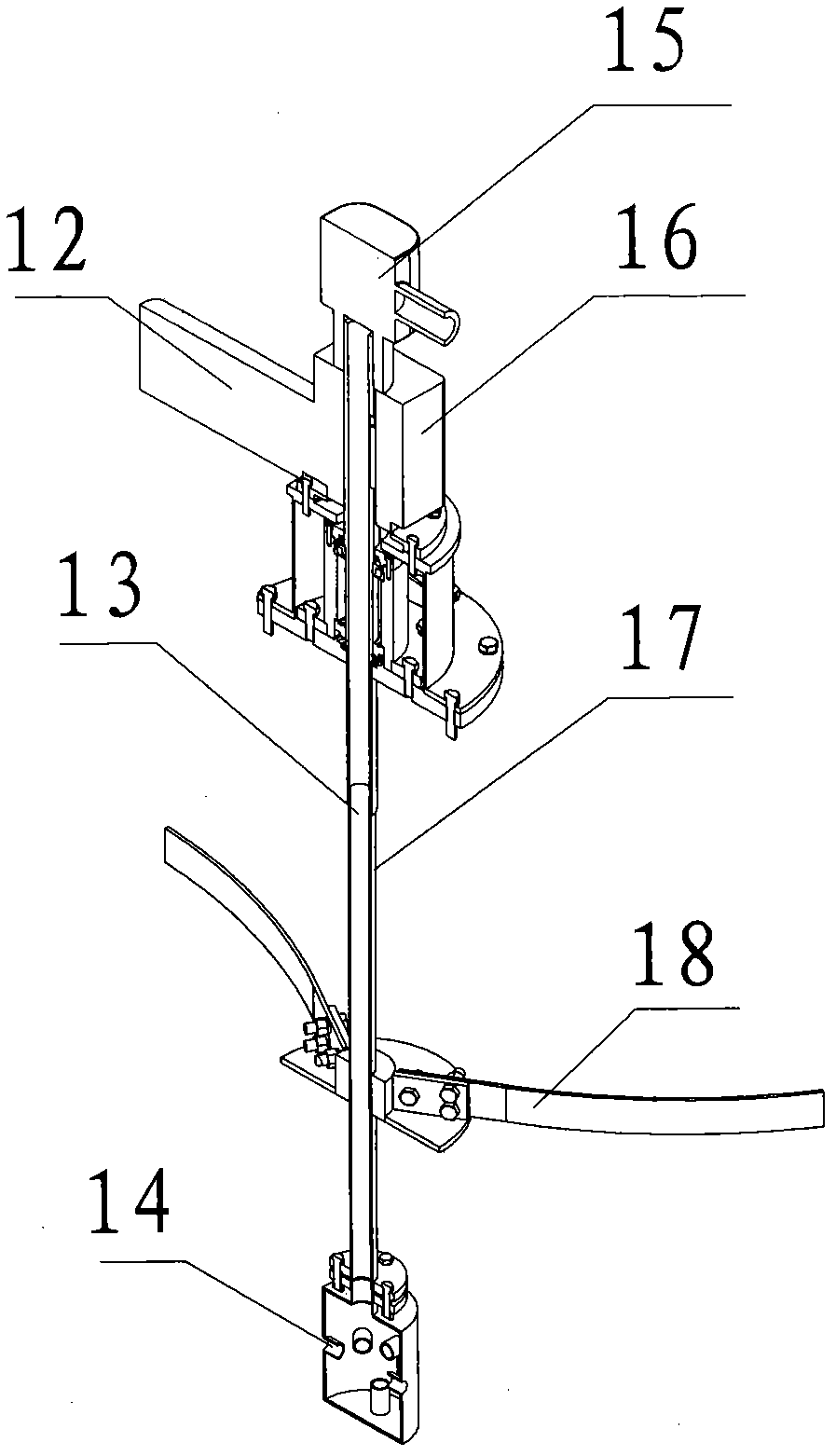

[0040] according to image 3 As shown, the furnace top stirring air distribution device 7 is composed of a motor 12, a reducer 16, a hollow transmission shaft 17 and a stirring blade 18. The upper end of the hollow transmission shaft 17 is connected to the motor 12 and the reducer 16, and the lower end is connected to the stirring blade 18. The top of the shaft 17 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com