A Straight Valve Layered Dispenser with Special-shaped Liquid Inlet

A liquid inlet and dispenser technology, applied in the mechanical field, can solve problems such as straight-valve layered dispensers not working properly, liquid inlet impurity blockage, etc., to achieve easy wiring, good sealing settings, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

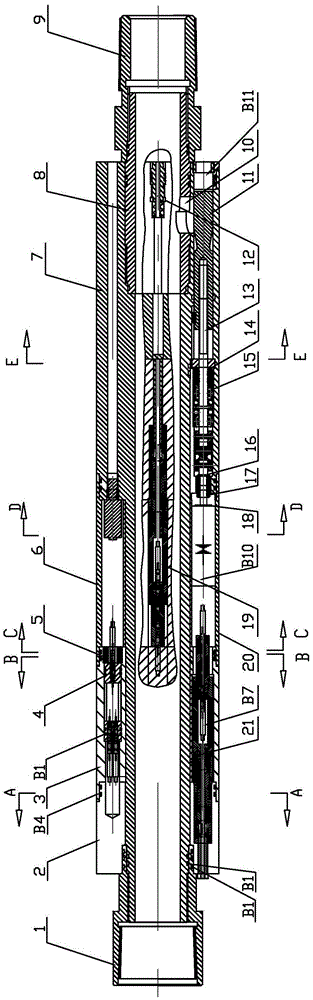

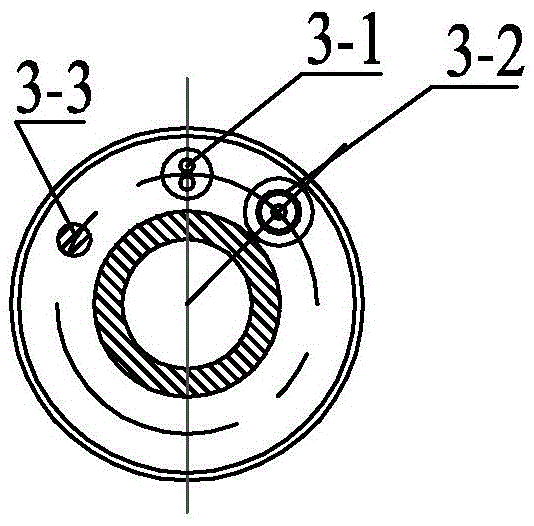

[0020] Specific implementation mode one: the following combination figure 1 , Figure 7 and Figure 8 Describe this embodiment, the straight-valve layered dispenser described in this embodiment includes a straight-valve layered dispenser body, which also includes: a special-shaped liquid inlet 10 and a cone valve 11;

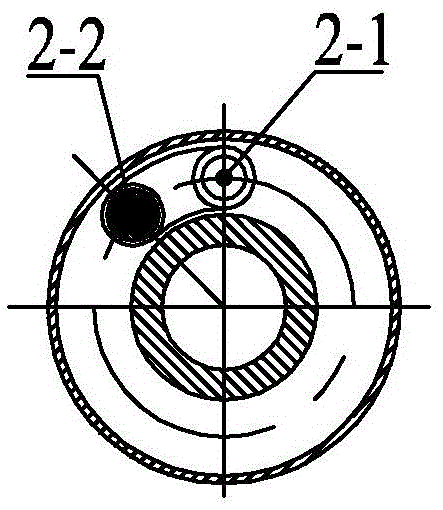

[0021] The special-shaped liquid inlet 10 is composed of a No. 1 circular through hole 10-1, a rectangular through hole 10-2 and a semicircular through hole 10-3 connected to each other. The No. 1 circular through hole 10-1, The rectangular through hole 10-2 and the semicircular through hole 10-3 communicate with each other. The centers of -3 are located on the same horizontal line, and the radius of the semicircular through hole 10-3 is smaller than the radius of the No. 1 circular through hole 10-1;

[0022] In the normal working state, the straight valve layered dispenser blocks the No. 1 circular through hole 10-1 of the special-shaped liquid inlet 10 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com