Non copper plating solid welding wire used for carbon dioxide gas protective arc welding

A solid wire, arc protection technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of welding current fluctuation, poor feedability, low copper melting point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

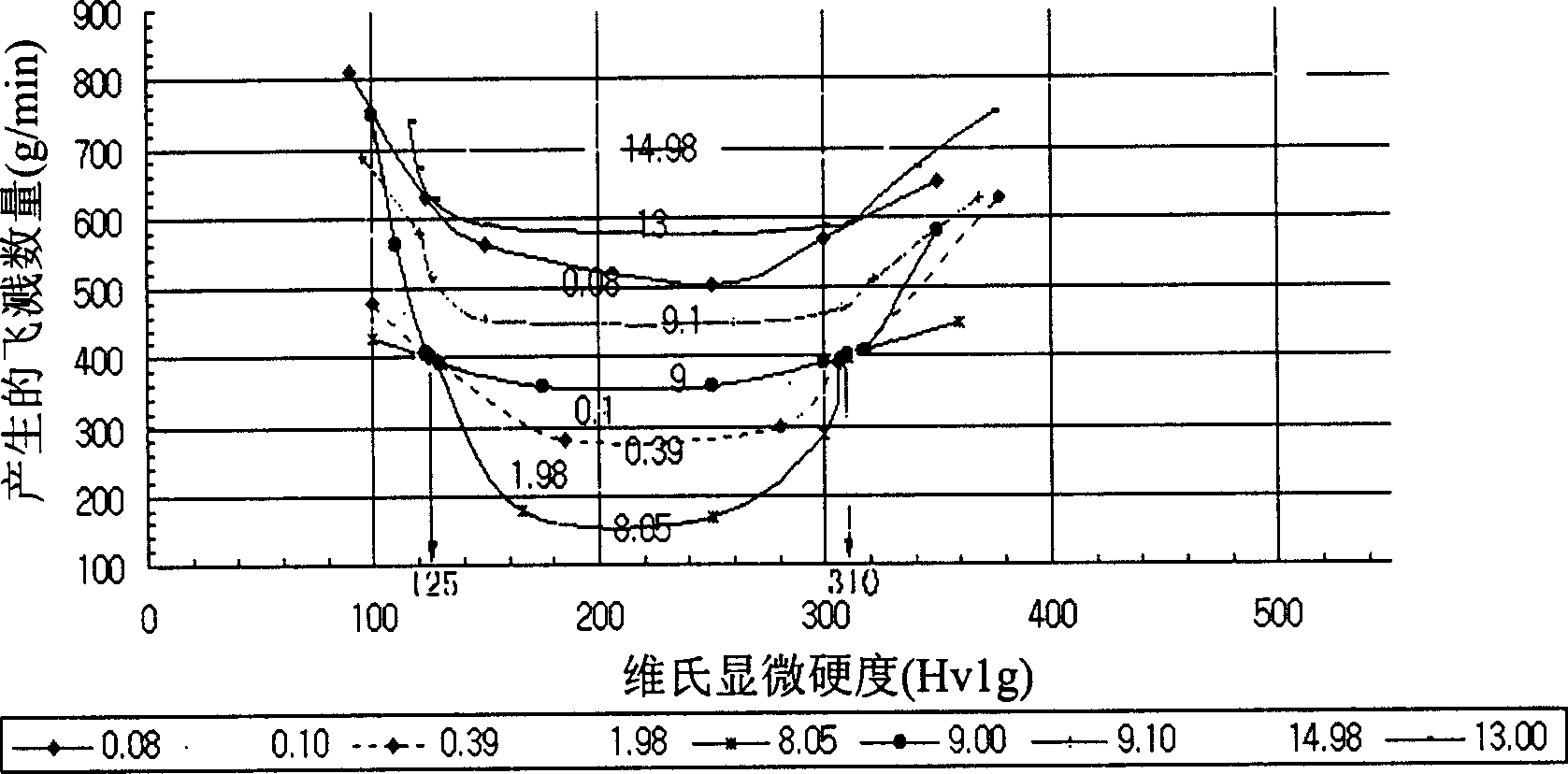

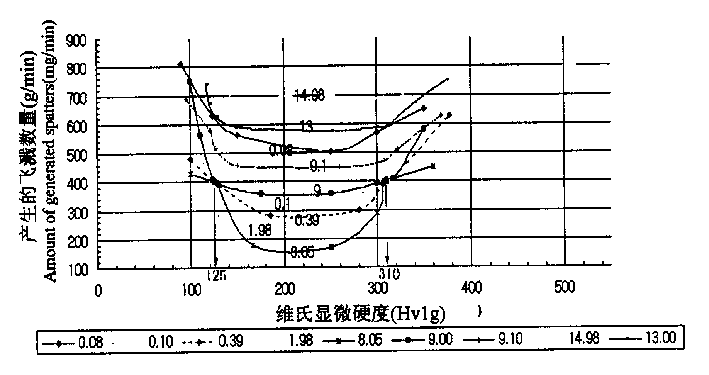

[0042] The effects of the present invention are described below by way of examples of the present invention and non-limiting comparative examples.

[0043] Manufactured containing, according to the chemical composition of the welding wire, 0.06wt% of C, 0.9wt% of Si, 1.4wt% of Mn, 0.014wt% of P, 0.009wt% of S, and 0.11wt% of Ti, and the diameters were 8mm, 6.4mm and 5.5mm starting wire (ROD). These wires operate at 45°C in 15% H 2 SO 4 Electrolytic pickling in solution.

[0044] Some pickled wires were grit blasted, others were not. During the blasting process, the surface roughness of the welding wire can be changed by changing different blasting speeds, such as slow, medium, and fast.

[0045]Next, the wire was coated with a conventional phosphate film (phosphate treatment layer), coated with 15% borax, dried and coiled. The process from pickling to coating is an online process.

[0046] Subsequently, the wire is dry-drawn under conventional conditions, resulting in dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com