Laser enhancement device and electric arc welding system

A strengthening device and arc welding technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as poor quality of welding products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

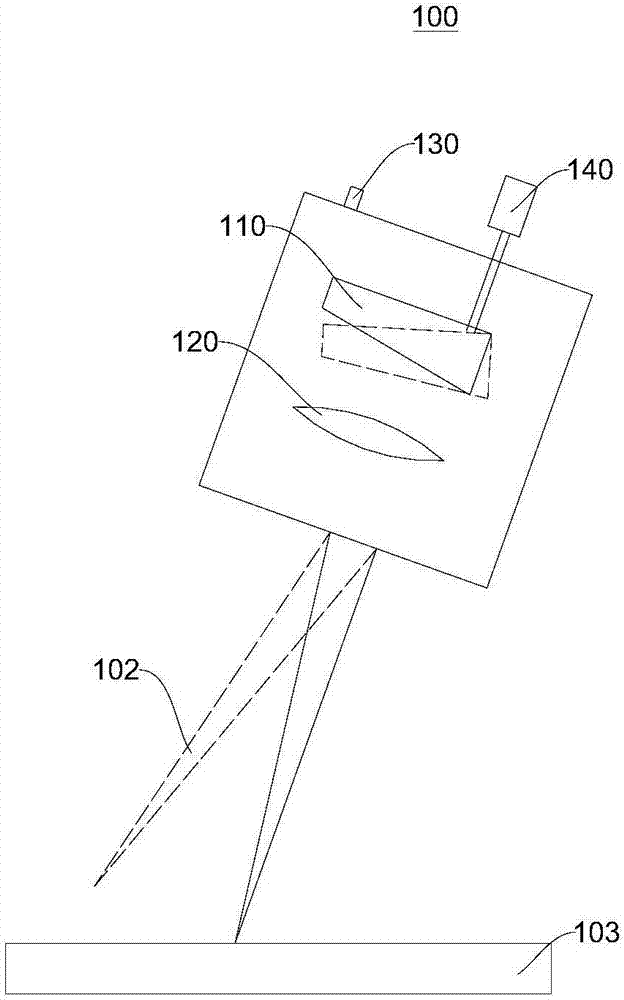

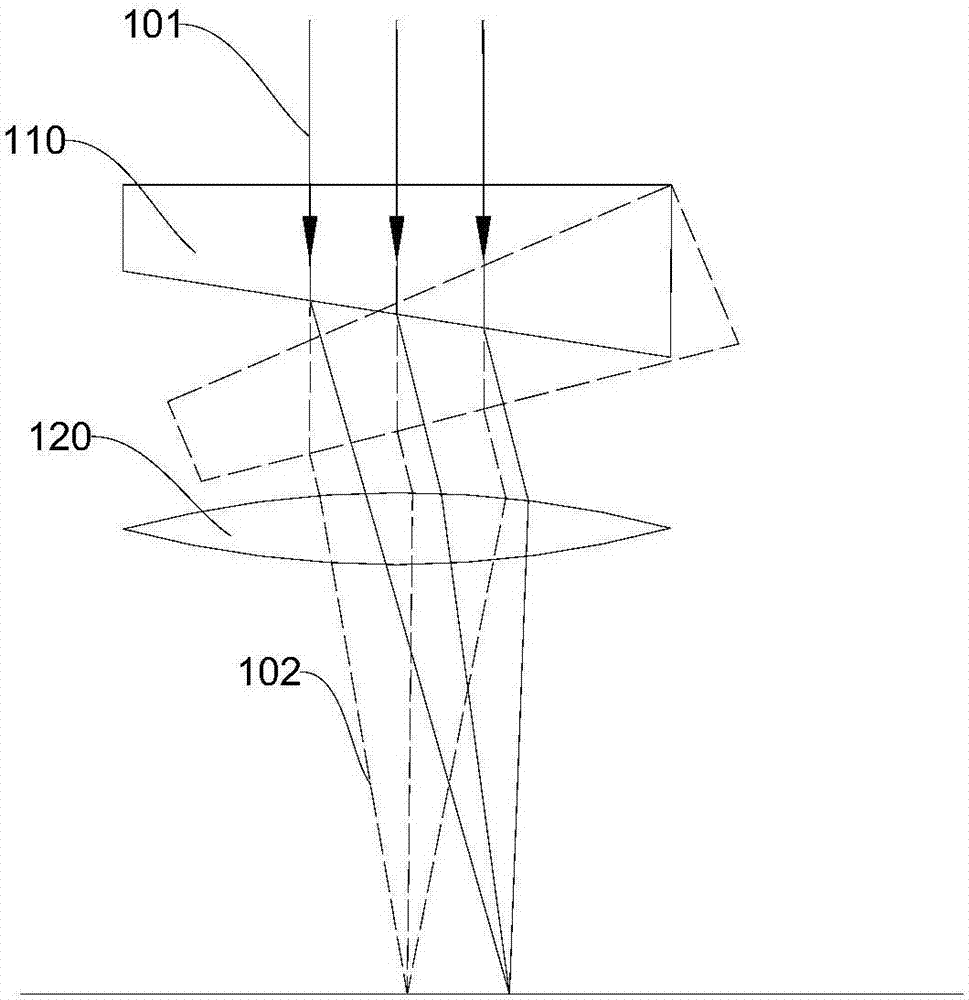

[0035] figure 1 For a schematic structural diagram of the laser intensifying device 100 provided in Embodiment 1 of the present invention, please refer to figure 1 . This embodiment provides a laser intensifying device 100. The laser intensifying device 100 includes an optical element 110, a focusing lens 120, an optical joint 130, and a driving device 140. The optical joint 130, the optical element 110, and the focusing lens 120 are used together. The laser 101 ( See figure 2 ) form the laser beam 102 through the optical joint 130, the optical element 110, and the focusing lens 120; the driving device 140 can drive the optical element 110 to rotate so that the laser beam 102 rotates along a preset track.

[0036] In this embodiment, the optical element 110, the focusing lens 120, and the optical joint 130 are all installed in the housing (not shown in the figure) of the laser intensifying device 100, and the optical element 110, the focusing lens 120, and the optical joint...

Embodiment 2

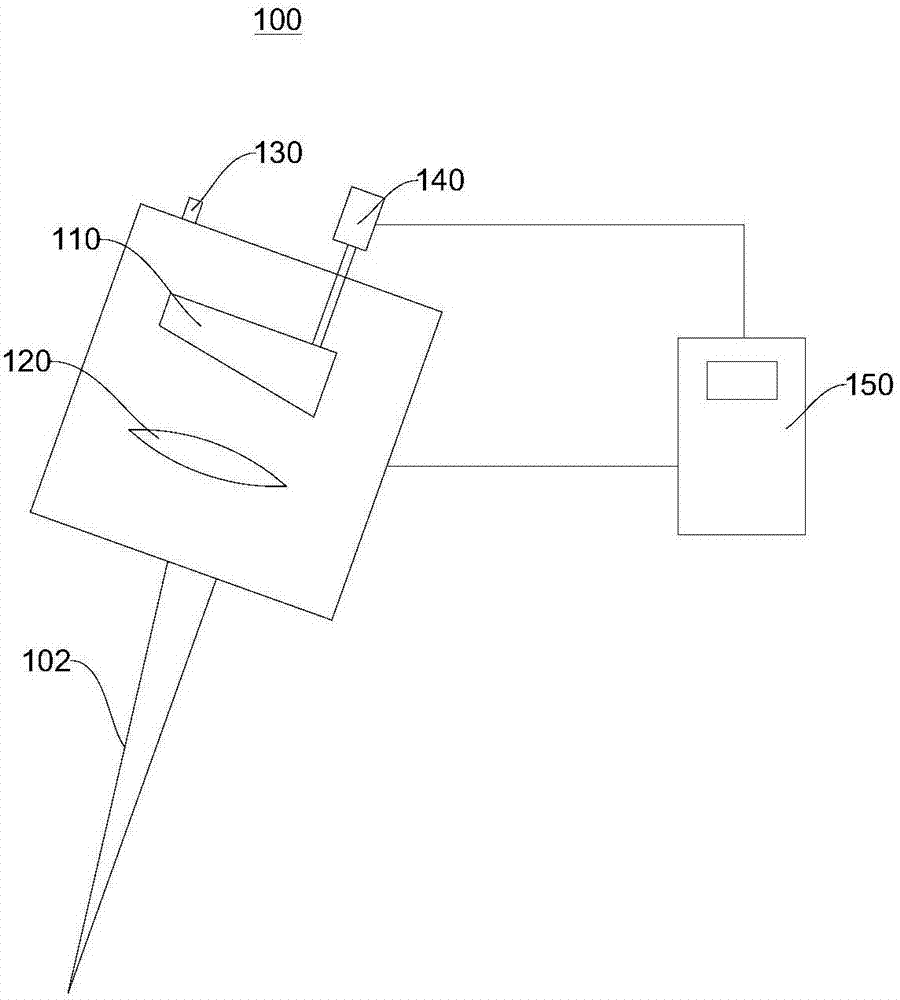

[0059] Figure 4 It is a schematic structural diagram of the arc welding system 200 provided in Embodiment 2 of the present invention, Figure 5 For a schematic diagram of the control principle of the arc welding system 200 provided in Embodiment 2 of the present invention, please refer to Figure 4 , Figure 5 , this embodiment provides an arc welding system 200, and the arc welding system 200 includes the laser intensifying device 100 of the first embodiment.

[0060] Further, the arc welding system 200 also includes a laser 210, a welding machine 230, and a welding torch 220. The welding machine 230 is used in conjunction with the welding torch 220. The laser 210 emits laser light 101, and the laser 210 is connected to the optical joint 130 of the laser intensifying device 100. The laser light 101 emitted by the laser 210 enters the laser intensifying device 100 through the optical joint 130 .

[0061] In this embodiment, the welding torch 220 has an included angle θ wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com