Sealing type compressor

A compressor, sealed technology, applied in the direction of compressors, refrigerators, mechanical equipment, etc., can solve the problems of large oil level agitation, oil transition splash, etc., to reduce noise, size, and oil splash. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

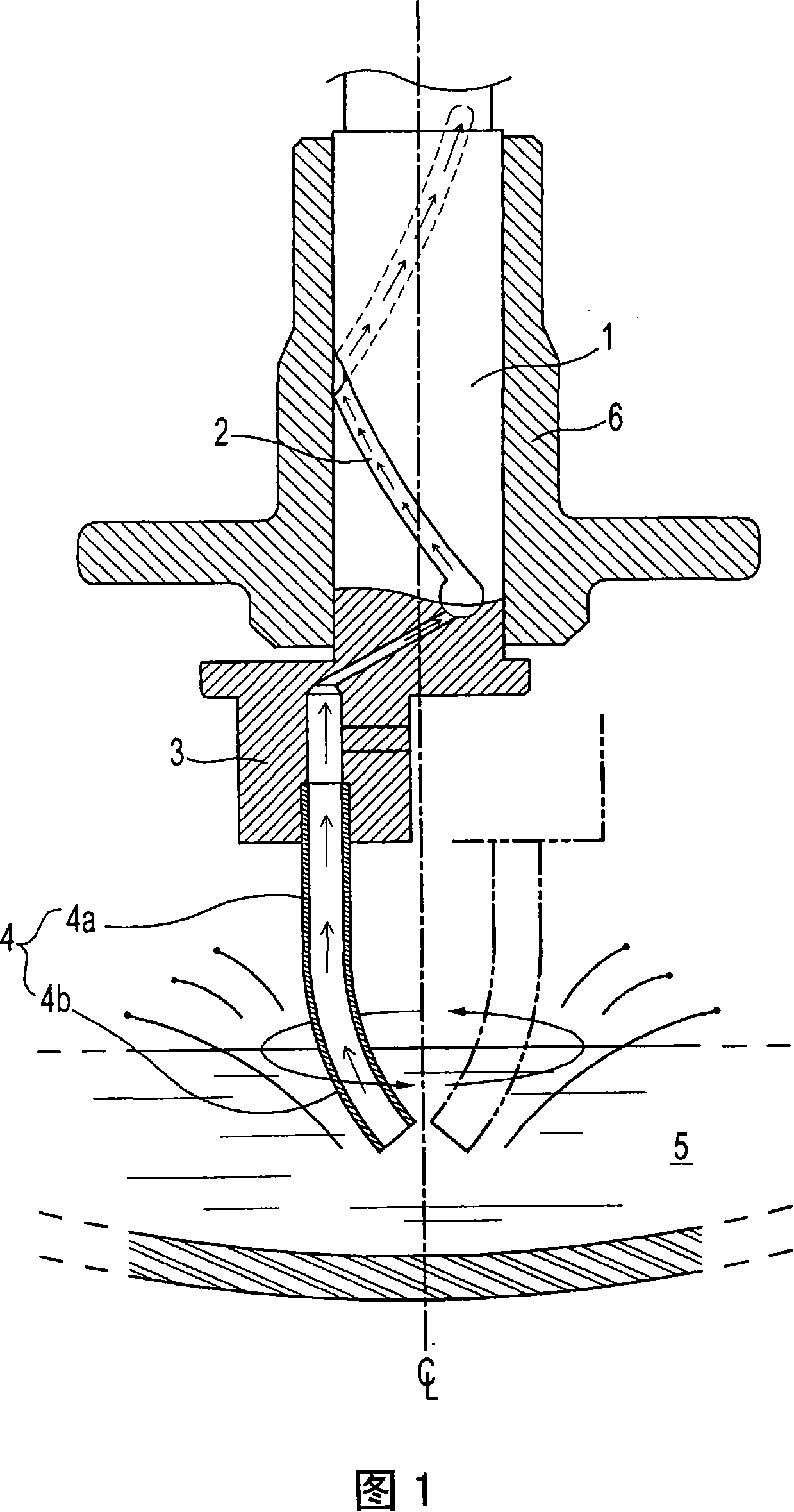

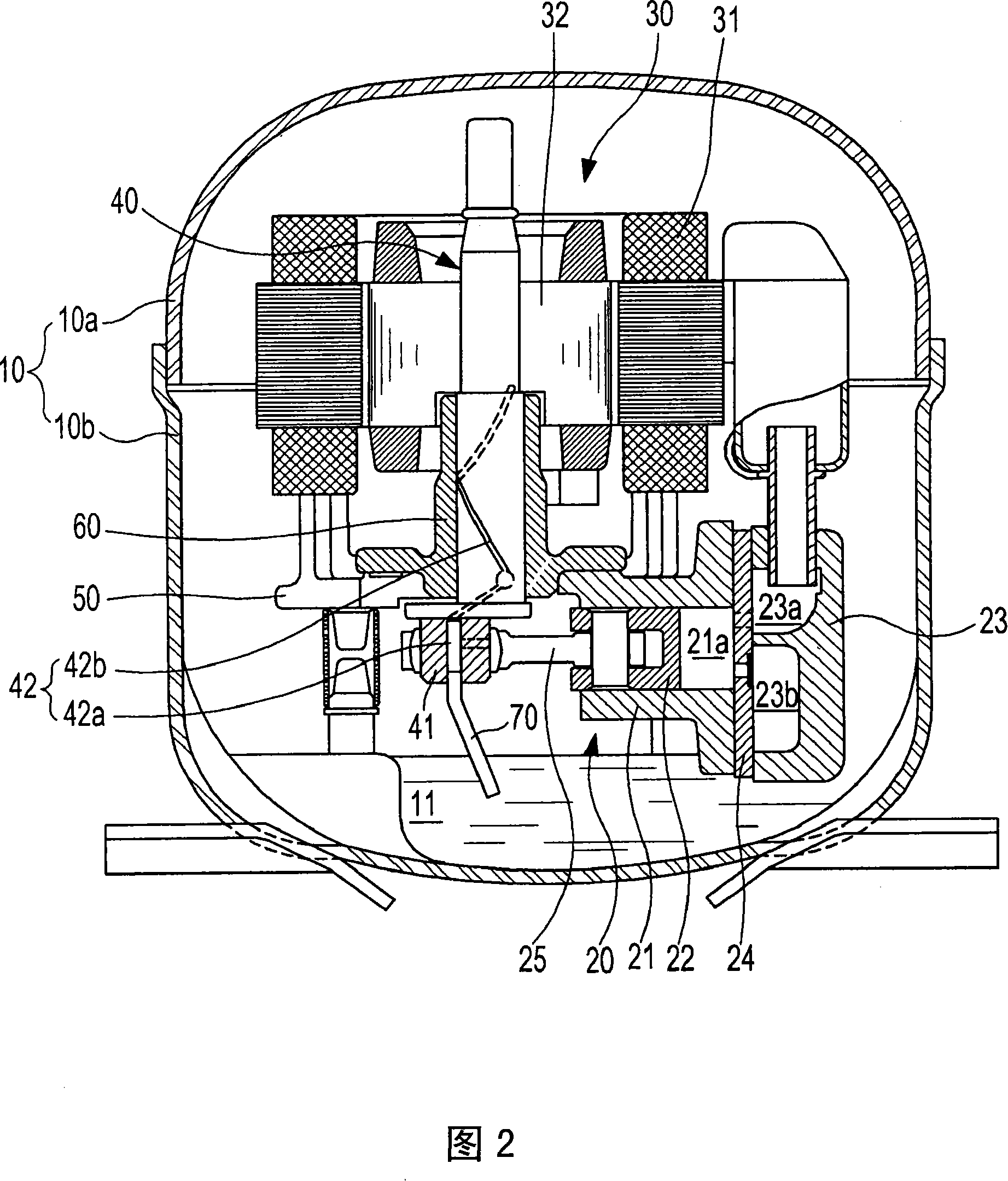

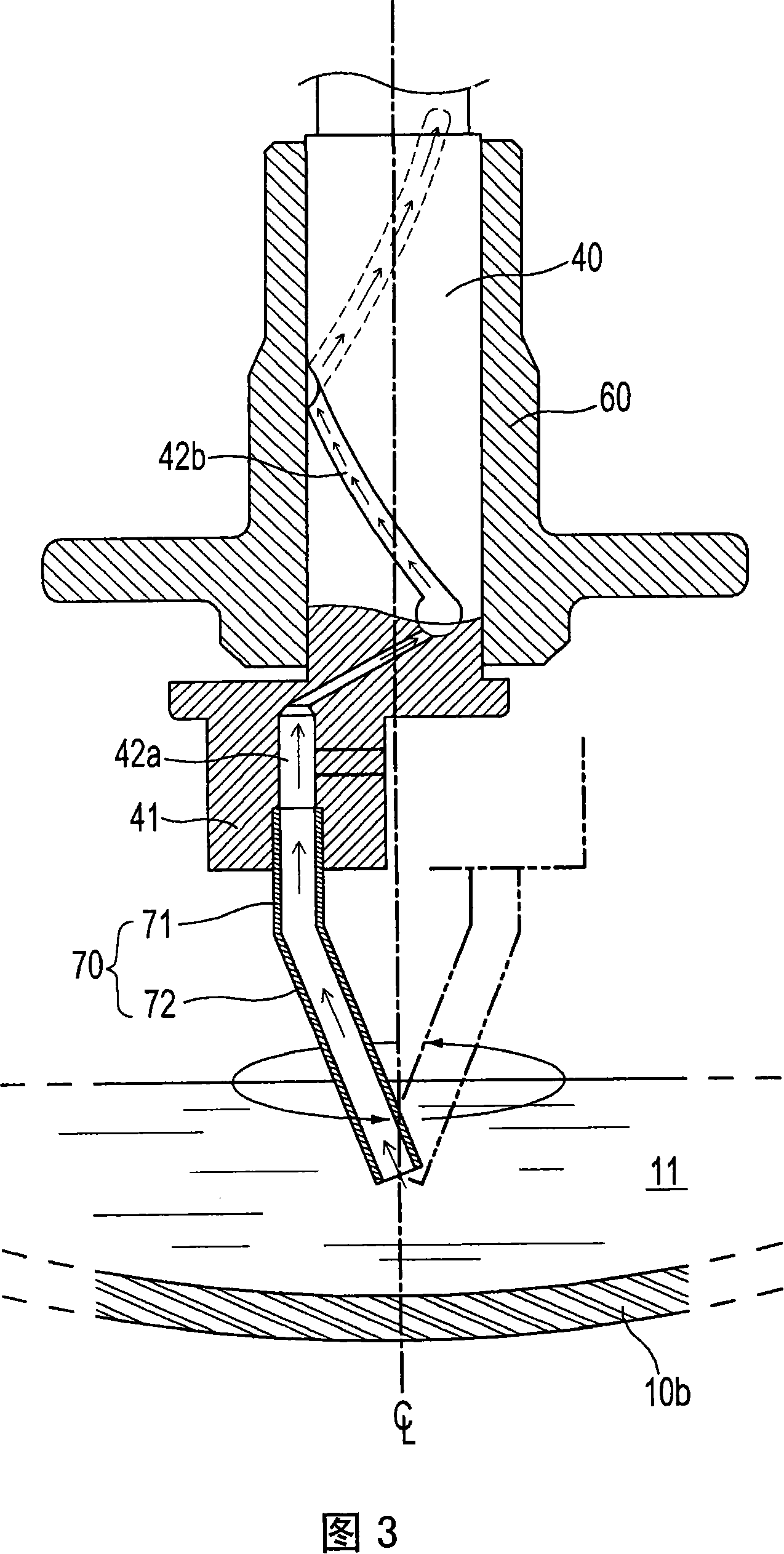

[0020] Hereinafter, the preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

[0021] As shown in FIG. 2, the compressor according to this embodiment includes: a sealed container 10, which is formed by combining an upper container 10a and a lower container 10b; Performing compression; a driving unit 30 that provides compression driving force for compressing the refrigerant; and a rotating shaft 40 that connects the driving unit 30 and the compression unit 220 to transmit the driving force of the driving unit 30 to the compression unit 20.

[0022] The drive unit 30 and the compression unit 20 are installed inside the sealed container 10 through a frame 50. First, the drive unit 30 includes a stator 31 fixed to the upper housing side of the frame 50; and a rotor 32 on the stator The inside of 31 is spaced apart, and it rotates by electromagnetic interaction with stator 31. Here, the above-mentioned rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com