Cast pipe self anchored interface

A self-anchored, cast pipe technology, which is applied in the direction of pipe/pipe joint/fitting, sleeve/socket connection, passing components, etc., can solve the problems of long construction period, poor pressure bearing capacity of pipeline, poor resistance to radial deformation, etc. Achieve the effects of shortening the auxiliary time, large pressure bearing capacity and preventing radial deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

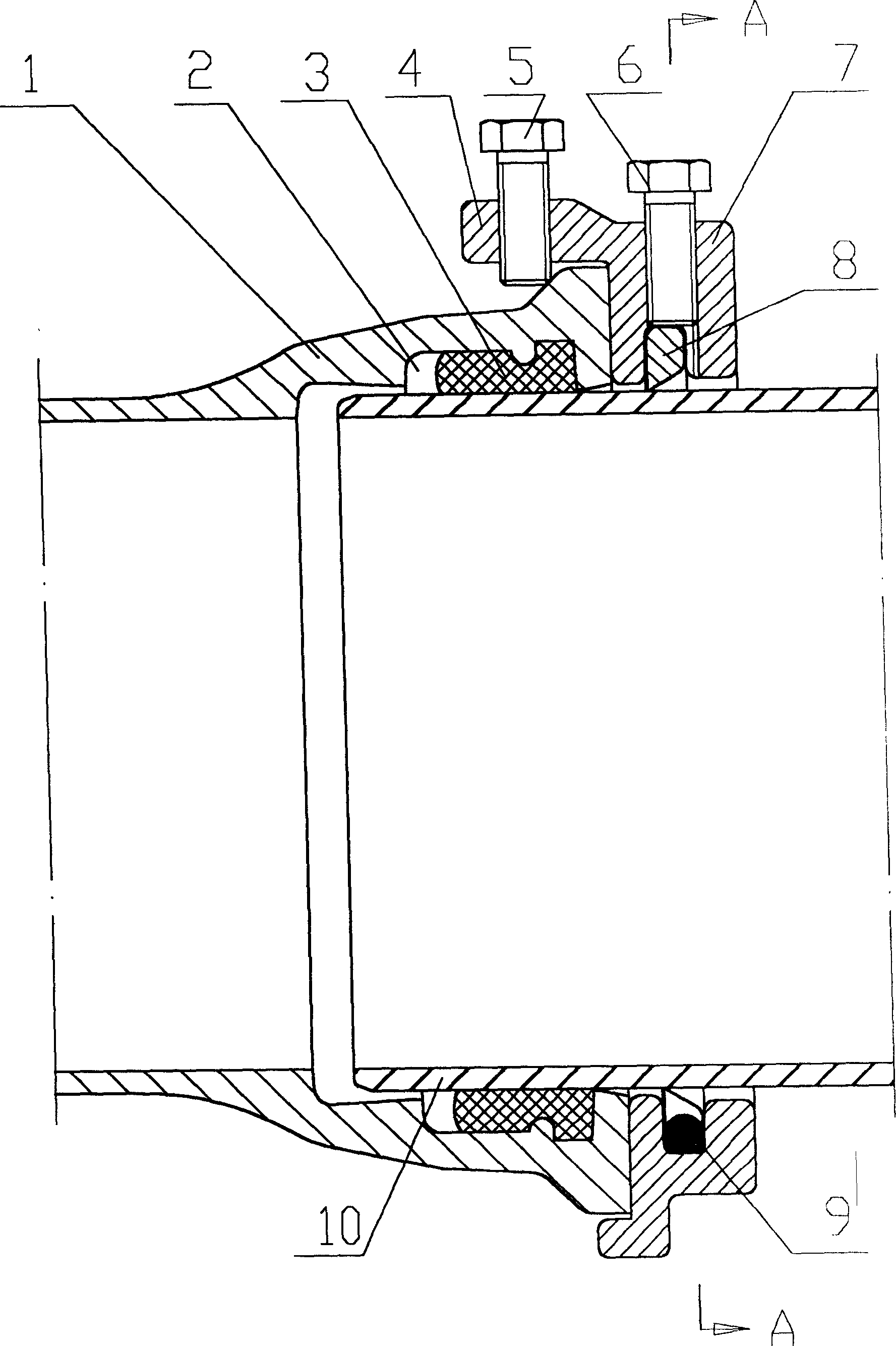

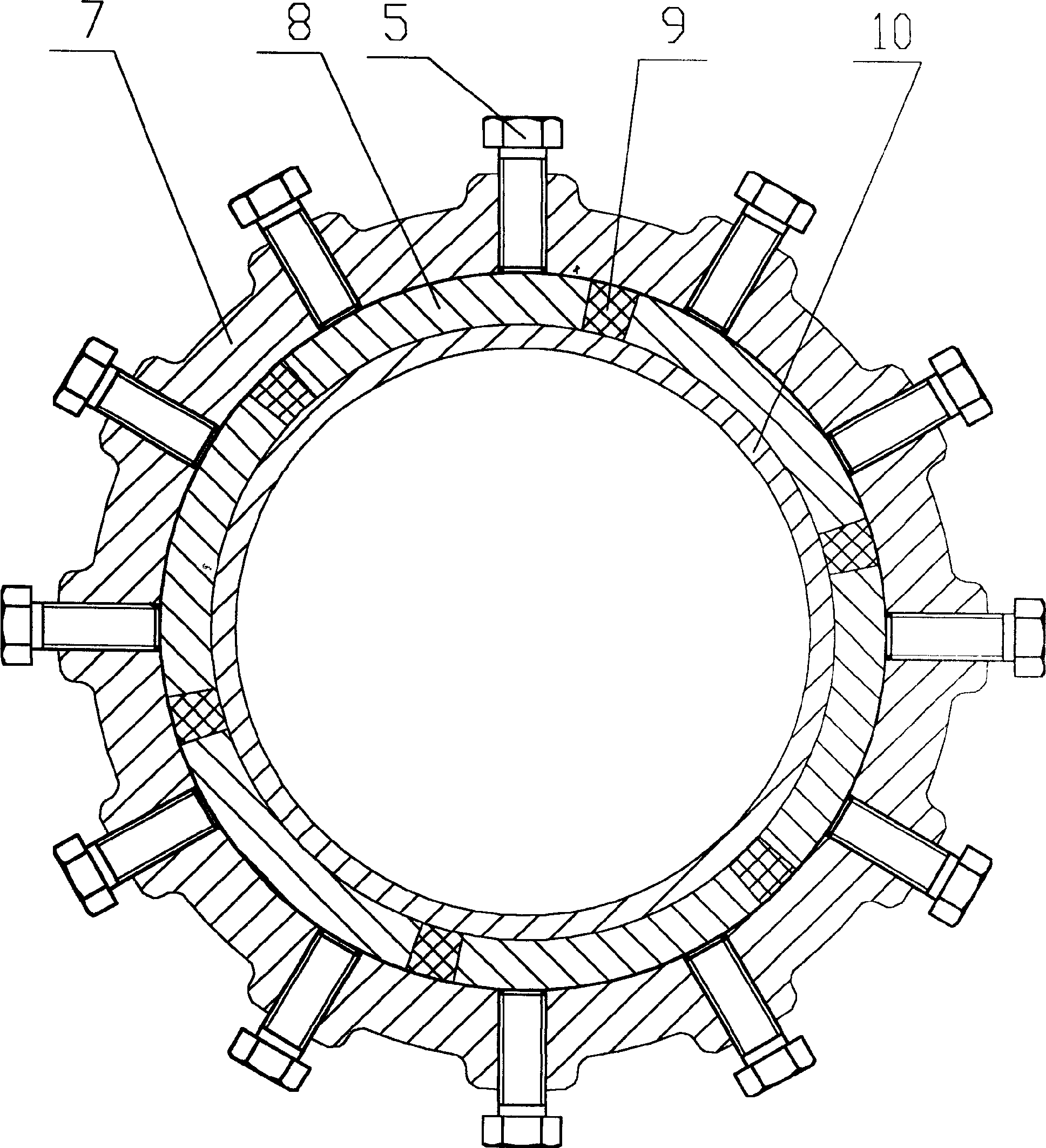

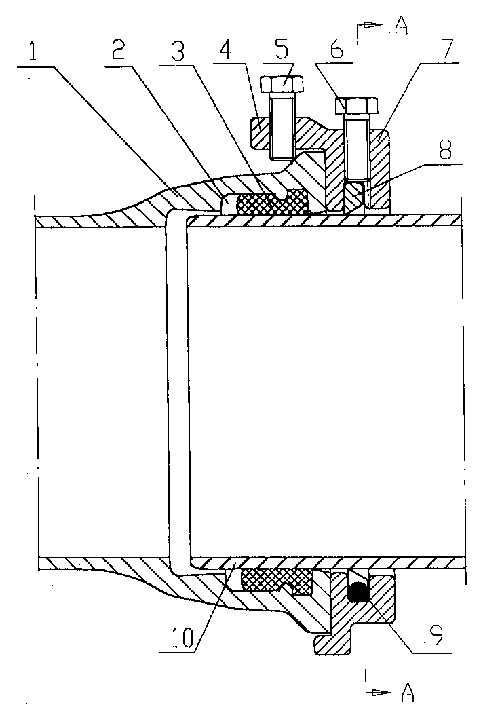

[0009] Put the sealing ring 3 in the inner groove 2 of the socket 1 of the casting pipe, insert the socket 10 of another casting pipe into the socket 1 of the casting pipe, and squeeze the sealing ring 3 tightly on the socket of the casting pipe Between port 1 and socket 10, such as figure 1 , 2 shown. A clamp 7 is sheathed on the outer cylindrical surface close to the junction of the cast pipe socket 1 and the socket 10, the clamp 7 is radially and evenly distributed to lock the threaded hole of the socket 10, and the shoulder 4 of the clamp 7 is radially Evenly distribute the threaded holes of locking socket 1. The threaded hole of the locking socket 10 is a groove near the outer cylindrical surface of the socket 10, and the pressure ring 8 is slidably installed in the groove, and the compression bolt 6 is screwed in the threaded hole of the locking socket 10, and the inner surface of the compression bolt 6 The end is pressed on the pressure ring 8. Tighten the compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com