Embossing roller and multi-section rubberized fabric which is formed by using said embossing roller and has no sharp angle in its end edge

An embossing wheel and embossing technology, which is applied in the field of embossing wheels with a special structure, can solve problems such as poor door curtain visibility, personnel collision, and turbidity of tape, and achieve good visual transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Further description will be made below with specific embodiments of the present utility model in conjunction with the accompanying drawings.

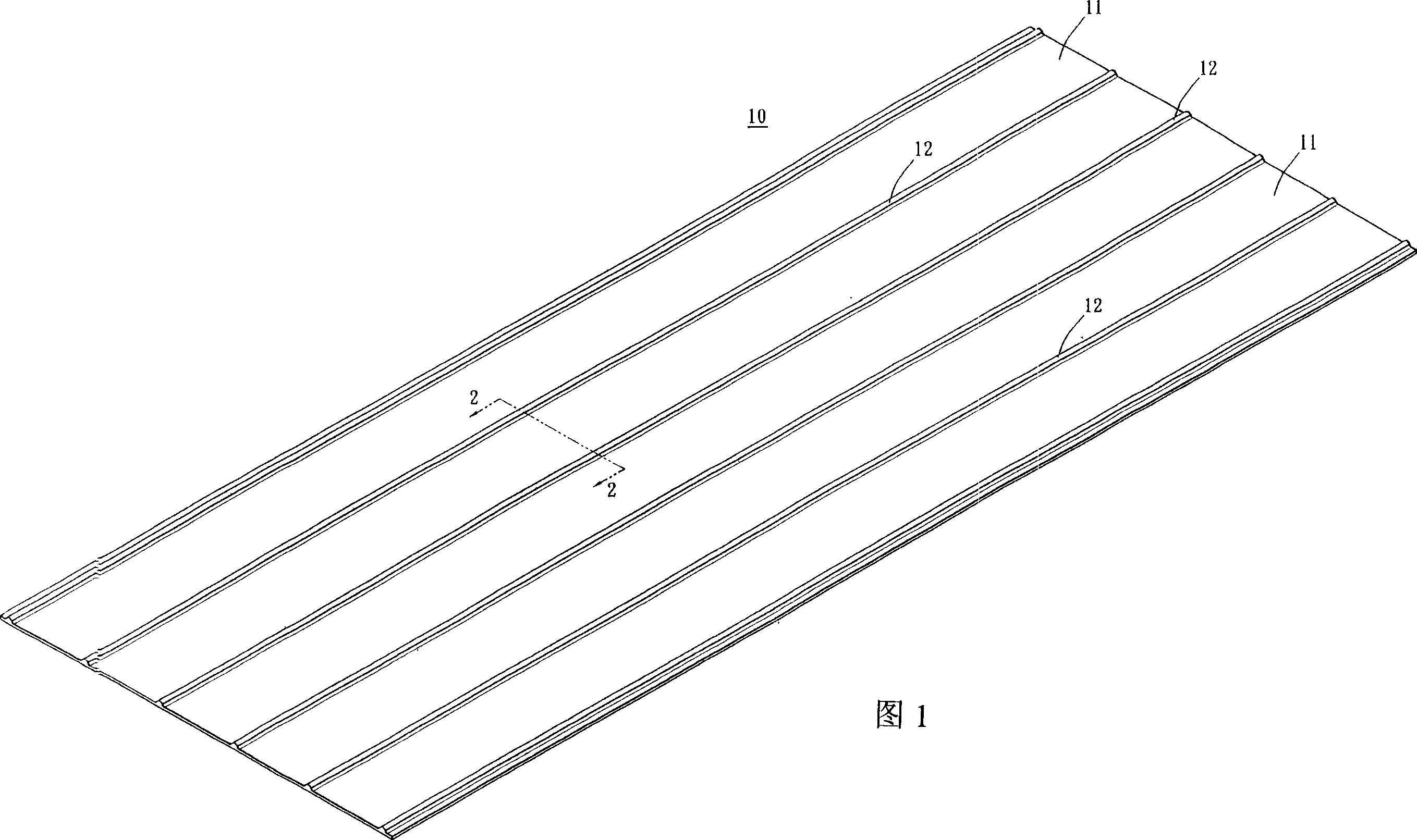

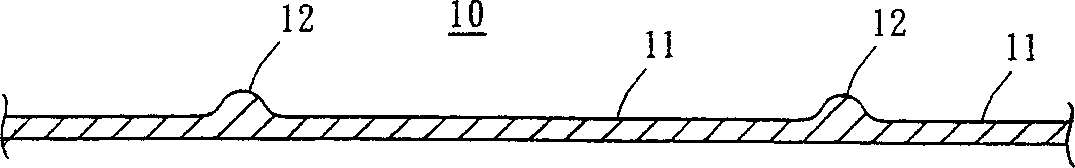

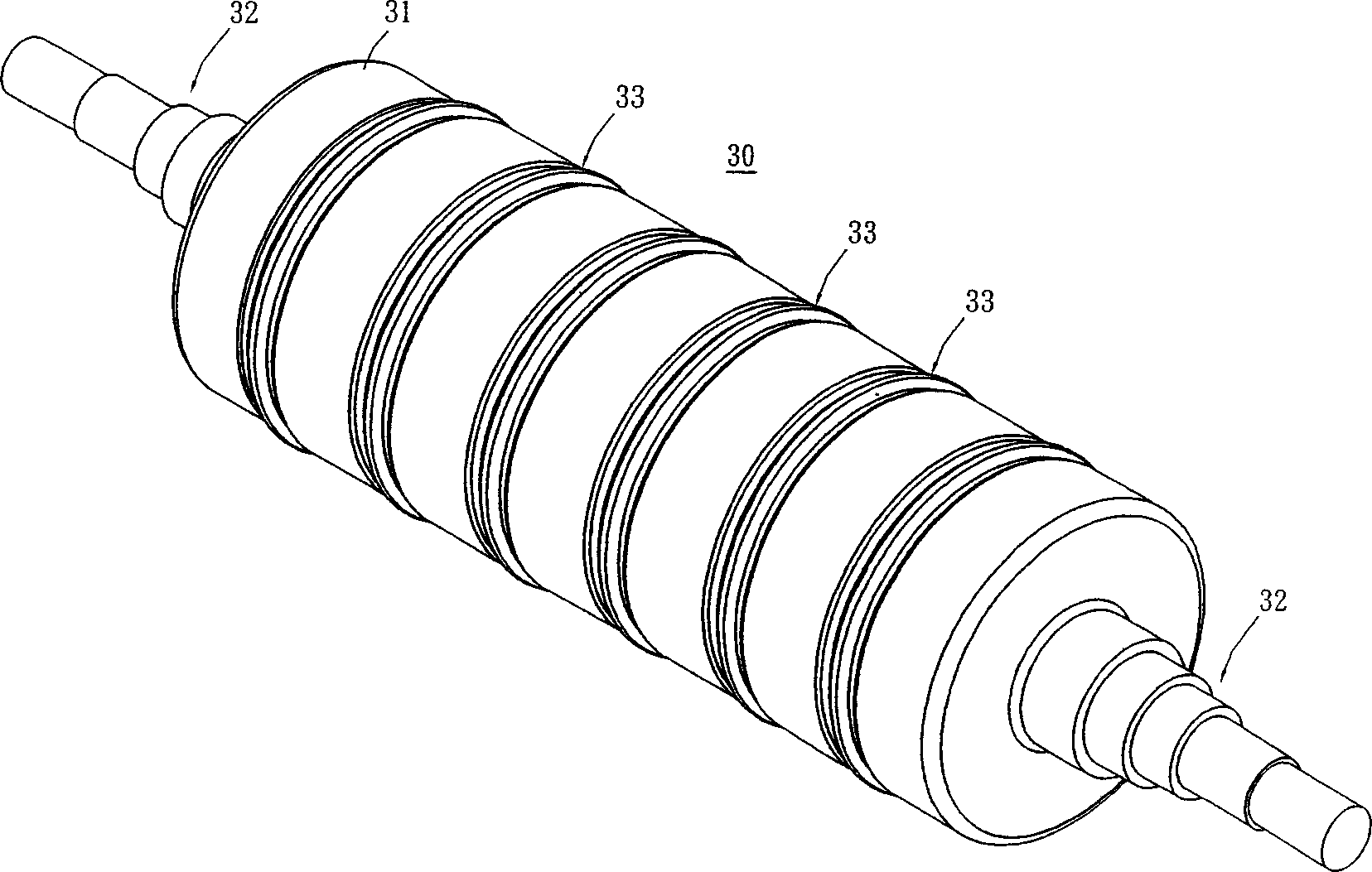

[0040] The embossed wheel tool 30 disclosed by the present invention has a structure such as Figure 3 to Figure 5 As shown, there is a wheel body 31 and two wheel shafts 32 arranged on the axle centers on both sides of the wheel body 31; on the wheel surface of the wheel body 31, a number of embossed grooves 33 are formed at equal intervals A. , and the wheel surface of the wheel body 31 and the embossing groove 33 are subjected to high-mirror treatment; moreover, for various thermoplastics or rubber polymers, the embossing wheel tool 30 of the present invention is suitable for embossing operations , in addition, the embossing wheel tool 30 of the present invention can be installed in such as Figure 6 to Figure 9 In the process of drawing rubber cloth of various plastics and rubber shown, it is used in conjunction with various...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com