Discharge apparatus for reciprocating compressor

An exhaust device, reciprocating technology, applied in the direction of liquid variable volume machinery, mechanical equipment, machine/engine, etc., can solve the problem of increasing exhaust cover pressure pulse, increasing exhaust cover noise, and impact noise that cannot be fully reduced. minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

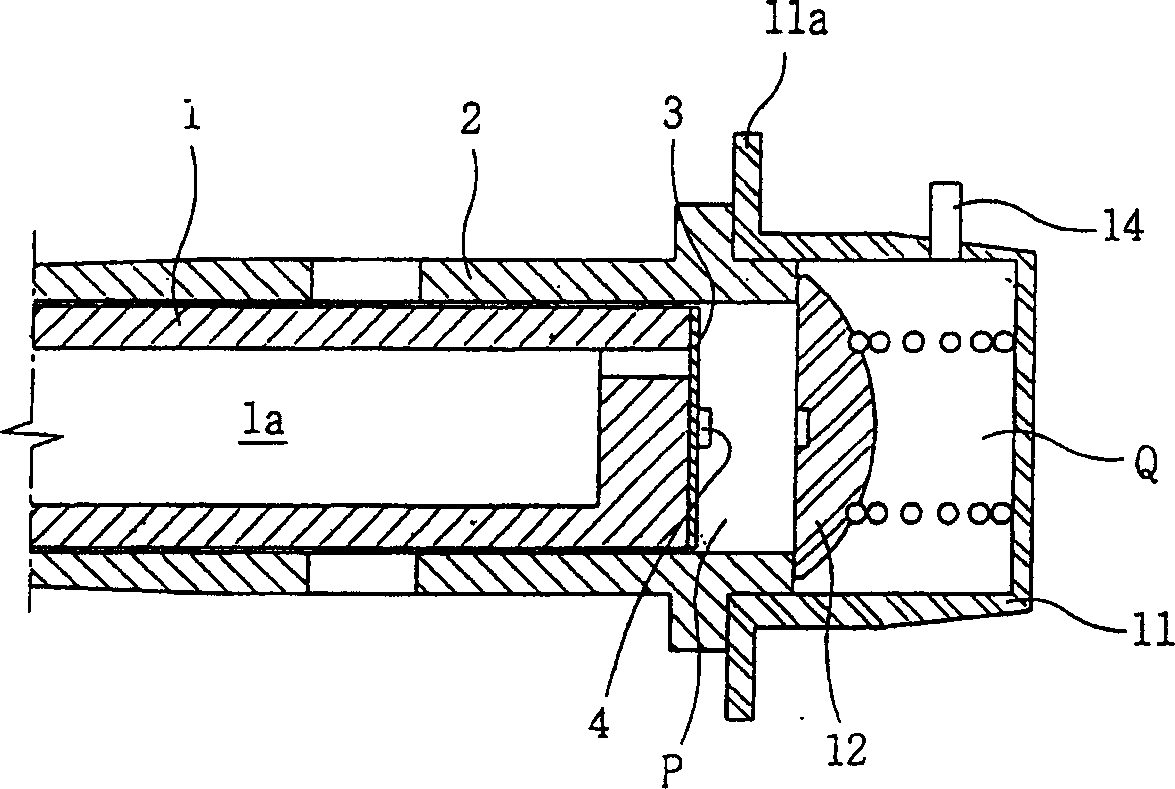

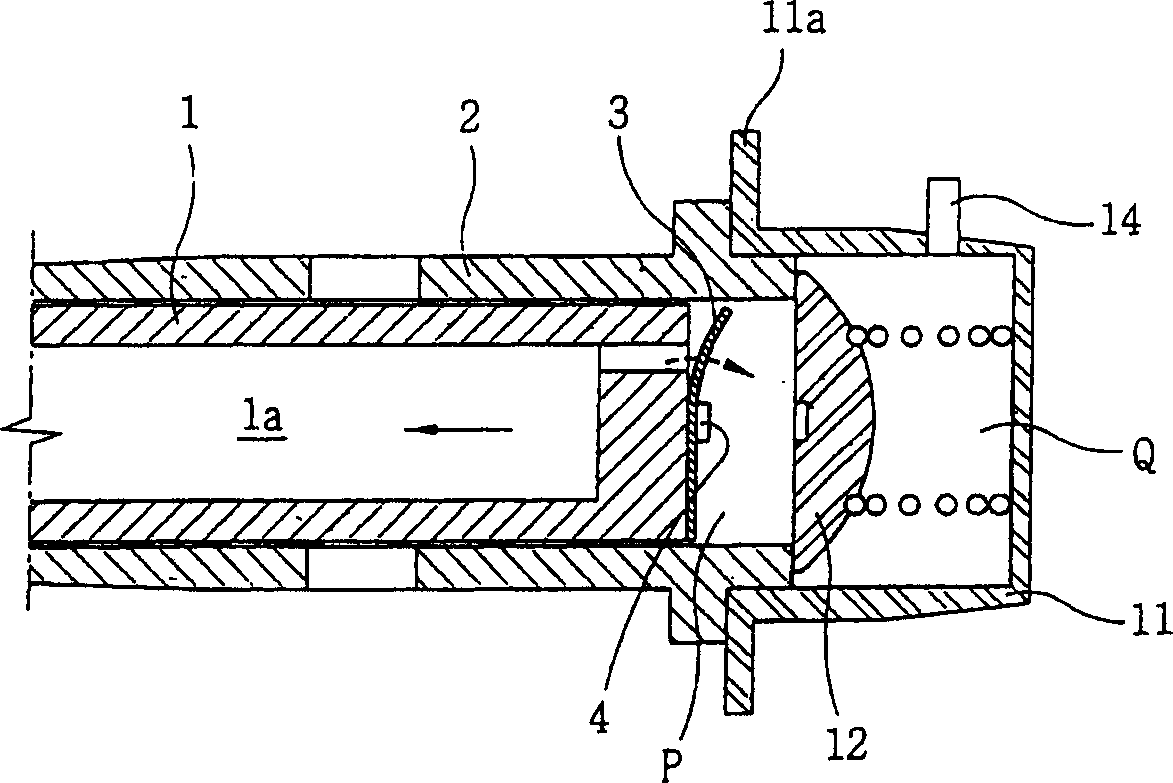

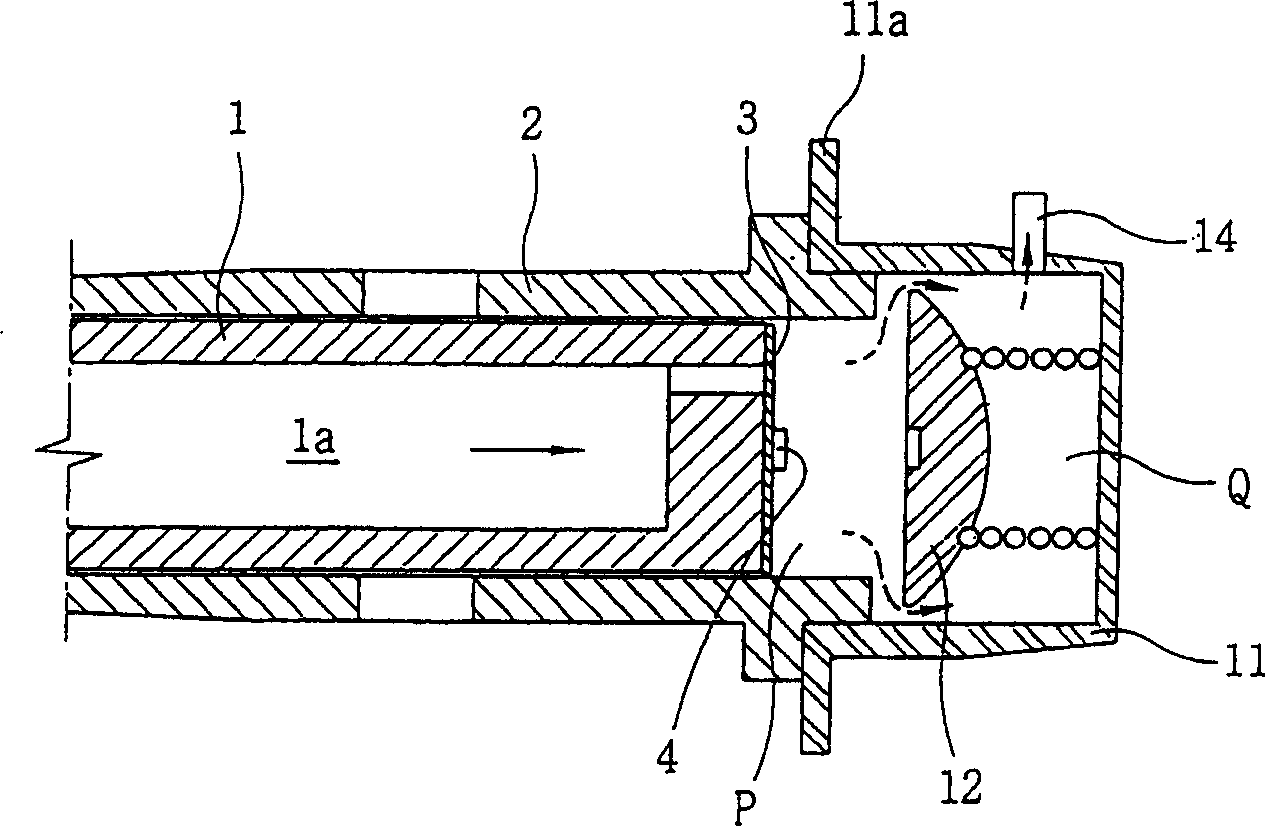

[0033] The exhaust device of the reciprocating compressor according to the present invention will be described below with reference to the drawings of the embodiments.

[0034] Components that are the same as those in the conventional art are denoted by the same reference numerals, and descriptions of the same functions thereof are omitted.

[0035] Next, a first embodiment of the present invention will be described.

[0036] Such as Figure 4 As shown, the exhaust device of the reciprocating compressor according to the present invention includes: a reciprocating piston 10, which receives a driving force from a vibrating device unit generating a driving force; a compression space P, in which gas is compressed by the piston 10 and the cylinder 20; The exhaust valve assembly 112 is used to open and close the compression space P according to the movement of the piston 10 in the exhaust cover 111, so as to cover the compression space P and discharge compressed gas, and the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com