Plant for manufacturing cement clinker

A technology of cement slag and cyclone dust collector, which is applied to furnaces, lighting and heating equipment, furnace types, etc., and can solve problems such as uneconomical use of heat and lowering of roasting furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

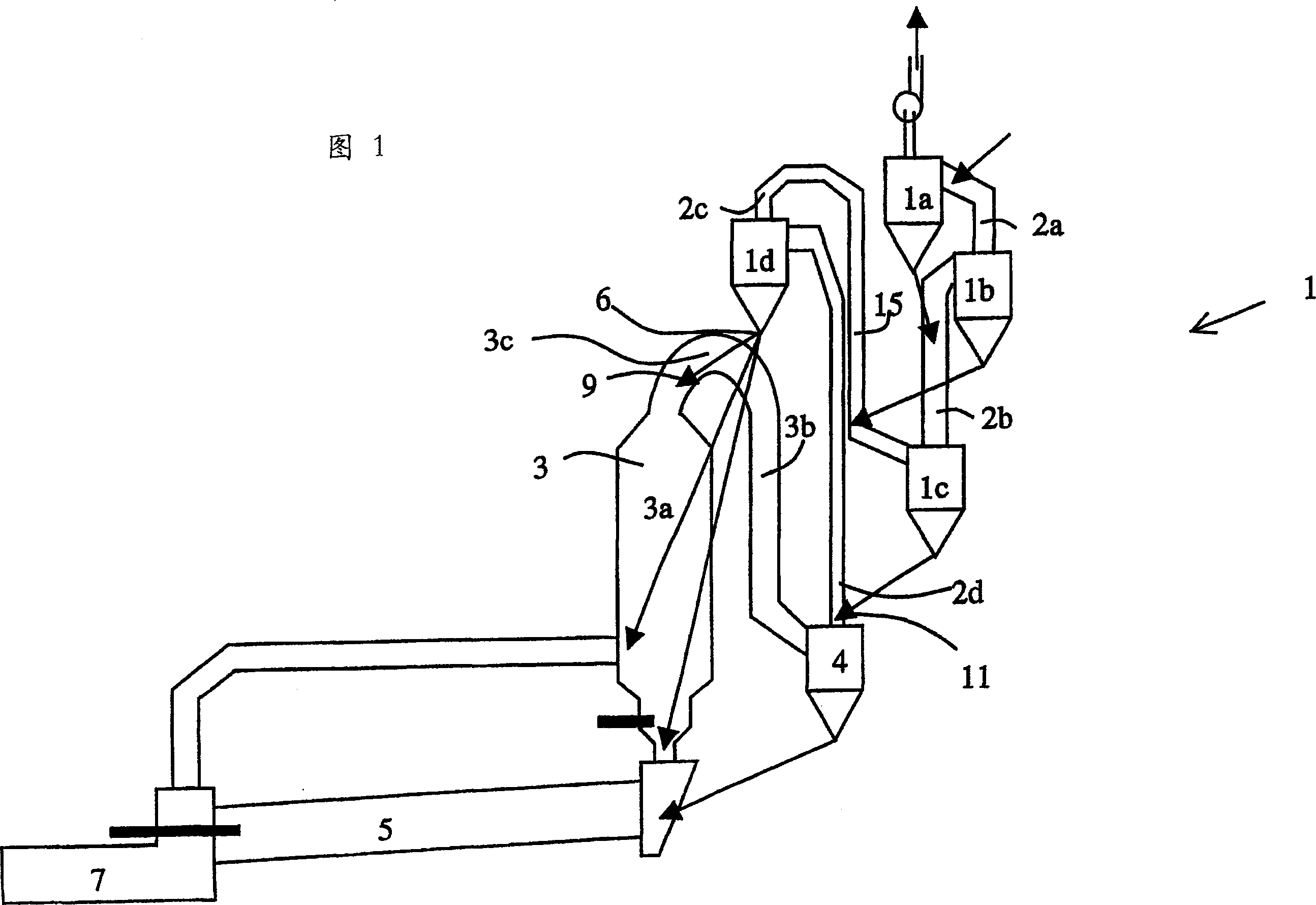

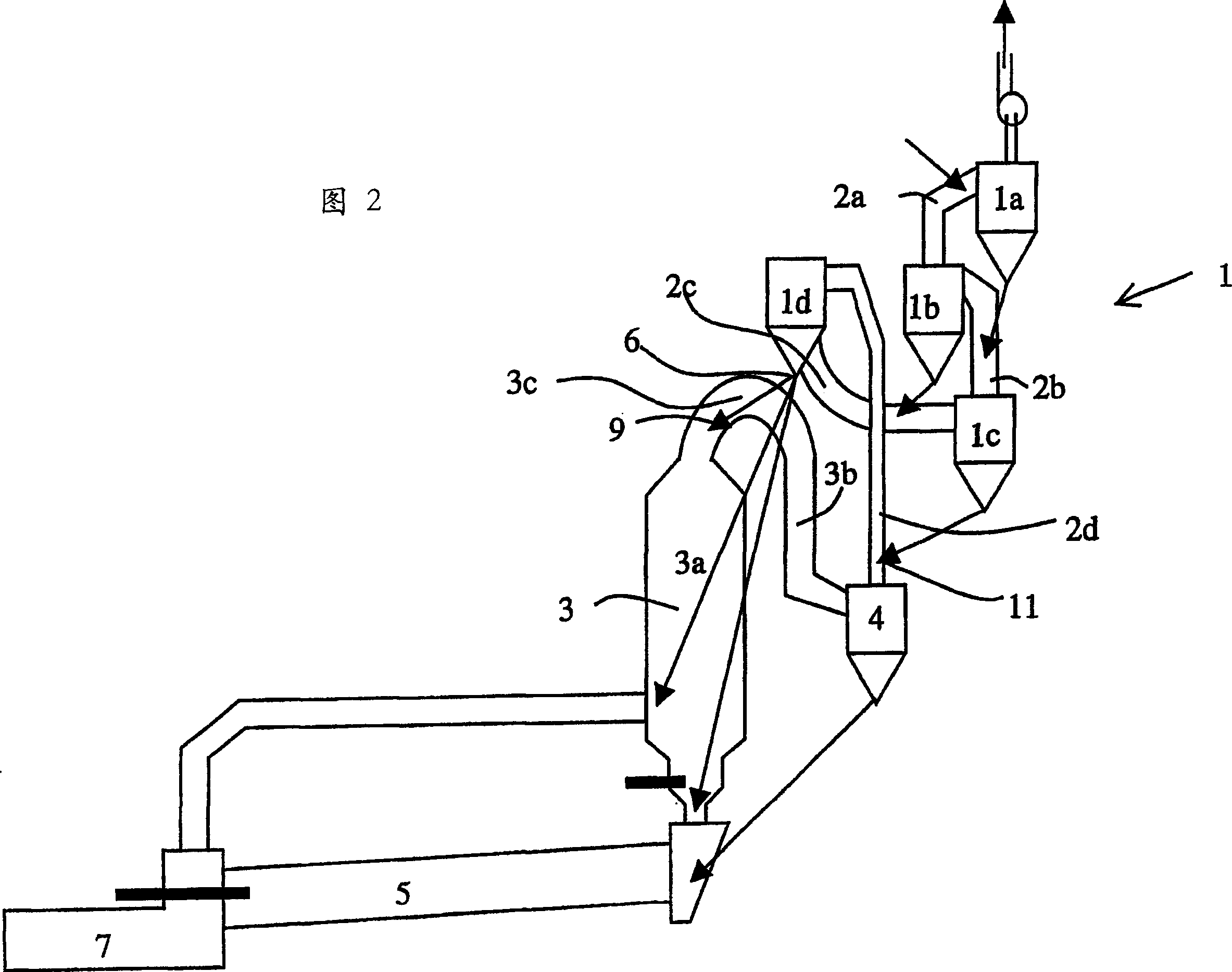

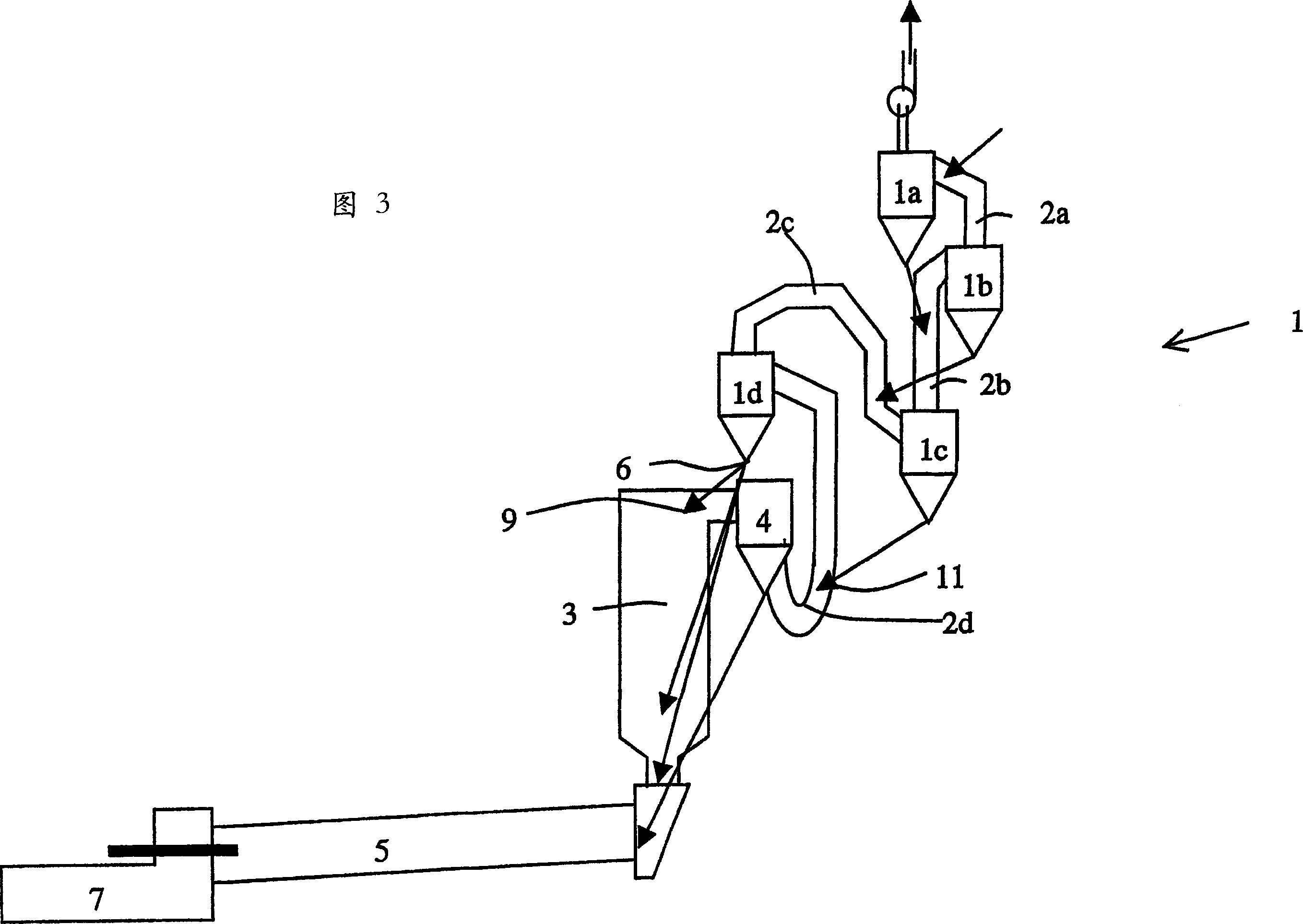

[0013] Figures 1 to 4 show examples of different kiln installations for the manufacture of cement clinker. All kiln units shown are of the ILC type, but the invention may also be used with units of the SLC type, or other combinations of such units.

[0014] All plants consist of a cyclone preheater 1 with 4 cyclones 1a, 1b, 1c and 1d. Among them, 1a is the first cyclone dust collector, 1b is the second cyclone dust collector, 1c is the third or penultimate cyclone dust collector, and 1d is the fourth or last cyclone dust collector. The cyclone dust collectors are connected in series and fed with gas / raw material coarse powder suspension through gas conduits 2a, 2b, 2c and 2d.

[0015] The apparatus also includes a calciner 3 comprising at least one inlet 9 for feeding preheated raw material meal from the last cyclone 1a through the material outlet 6; and with a separate cyclone 4 , The rotary kiln 5 is connected to a slag block cooler 7 . The gas duct 2d connecting the sepa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap