Step distributed downhole parellel blowing fan station

A step-type, fan station technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve the problems of increased operating costs of the ventilation system, large local resistance of the fan station, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

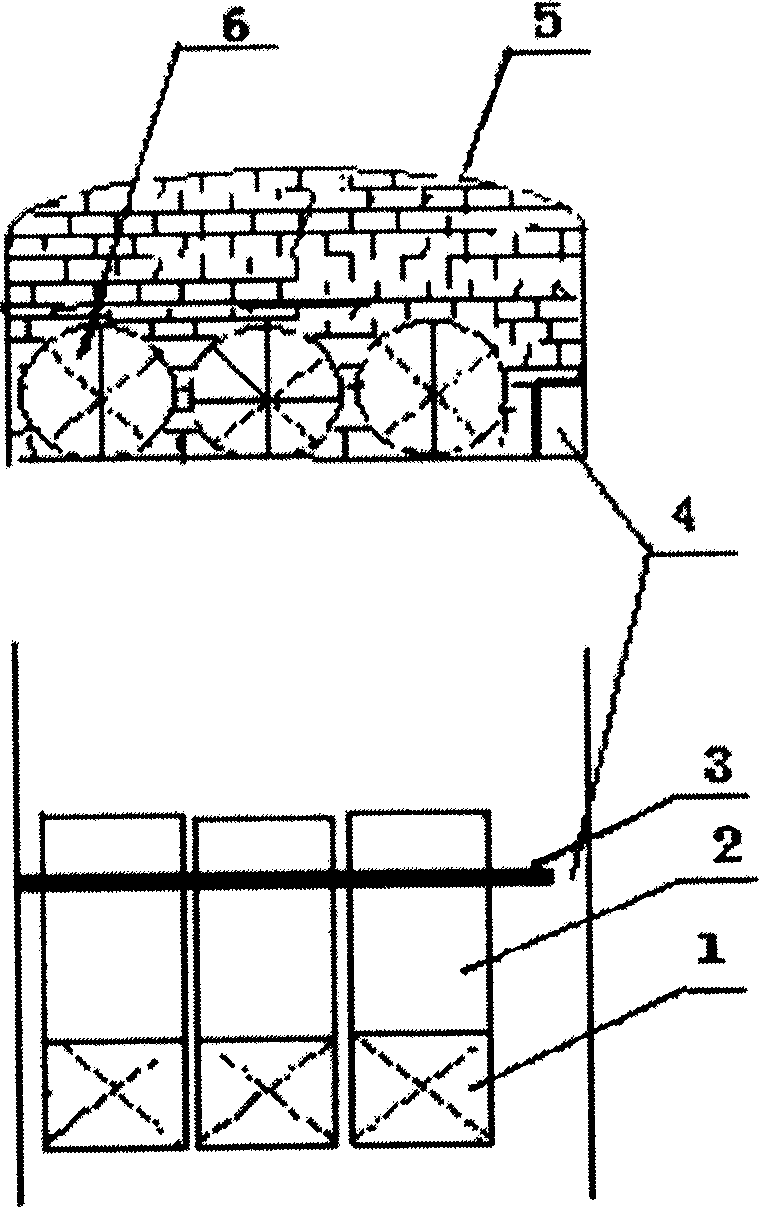

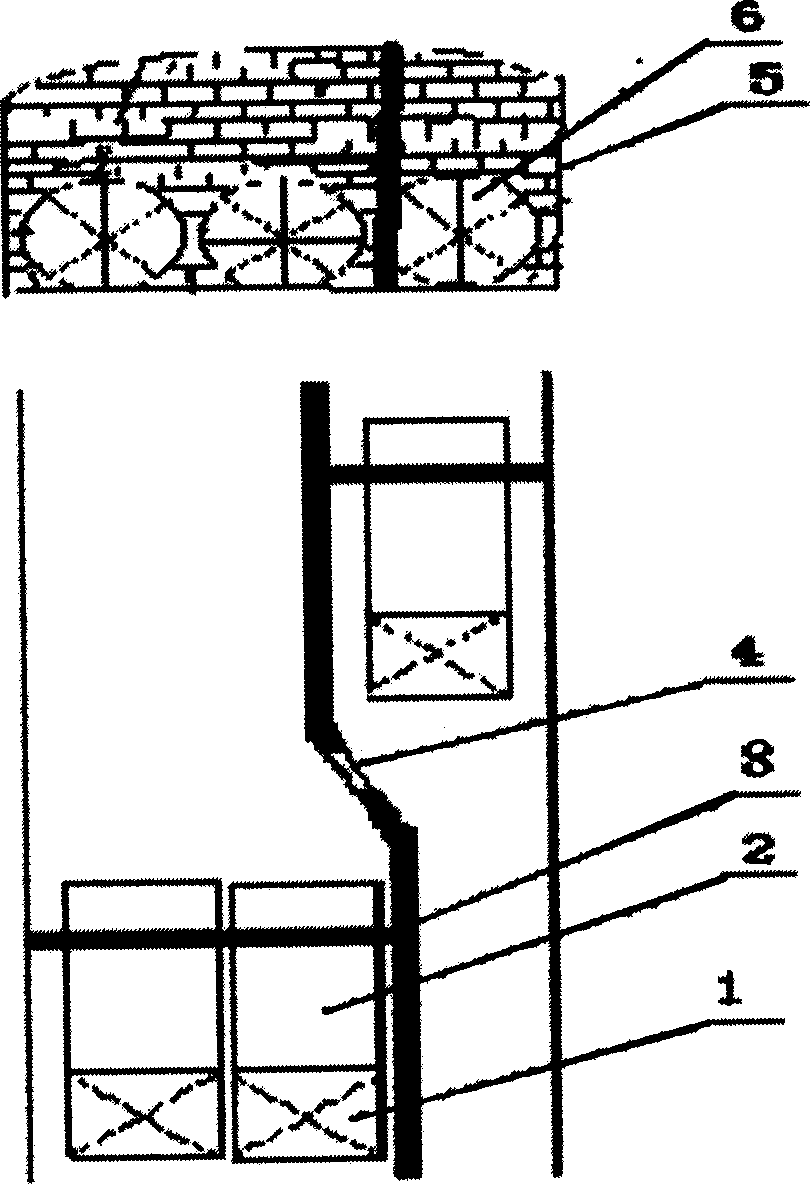

Embodiment 1

[0007] Example 1: A total of 3 sets of K40-6-19 fans need to be installed in the wind shaft-198m horizontal machine station, with a single unit capacity of 110KW. The original roadway space is fully utilized to make the fan station arranged in steps, and the 6 fans of the machine station are divided into Two groups, one of which is installed in parallel on the same section of the roadway 5, and the other group of fans are arranged in steps at a distance from it, and the roadway is sealed by the air wall 3 at the fan diffuser 2, and the wind wall between the two groups of fans is used to seal the roadway. The wall 3 is partitioned, and the damper 4 is installed, which is convenient for personnel to overhaul and maintain the fan. When the fan is running, the air flow passes through the machine station, which generates less local resistance, reduces the operating cost of the ventilation system, and at the same time reduces the roadway space for the machine station installation, sa...

Embodiment 2

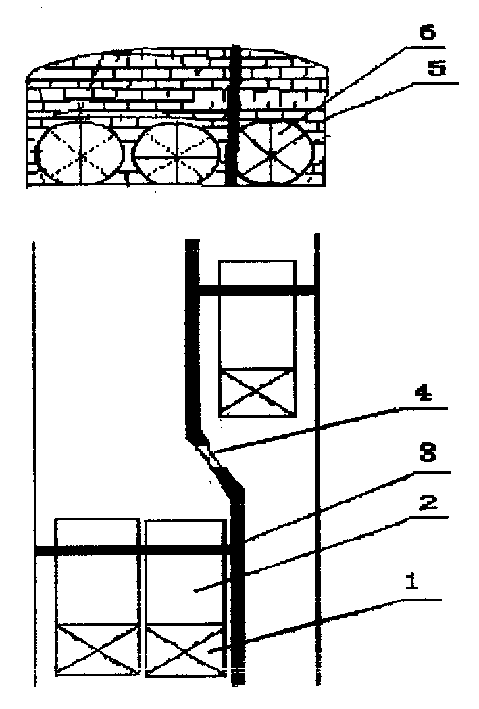

[0008] Embodiment 2: The fan station is composed of 3 groups of fans, each group of fans is connected in parallel by 2 fans, each group of fans is installed in a staggered position, and is arranged in the roadway in a stepped manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com