High-efficiency refuse sieving machine

A screening machine and garbage technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of no sorting effect, easy blockage of screen holes, and low sorting rate, so as to improve the sorting rate and labor efficiency, ensuring normal operation, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

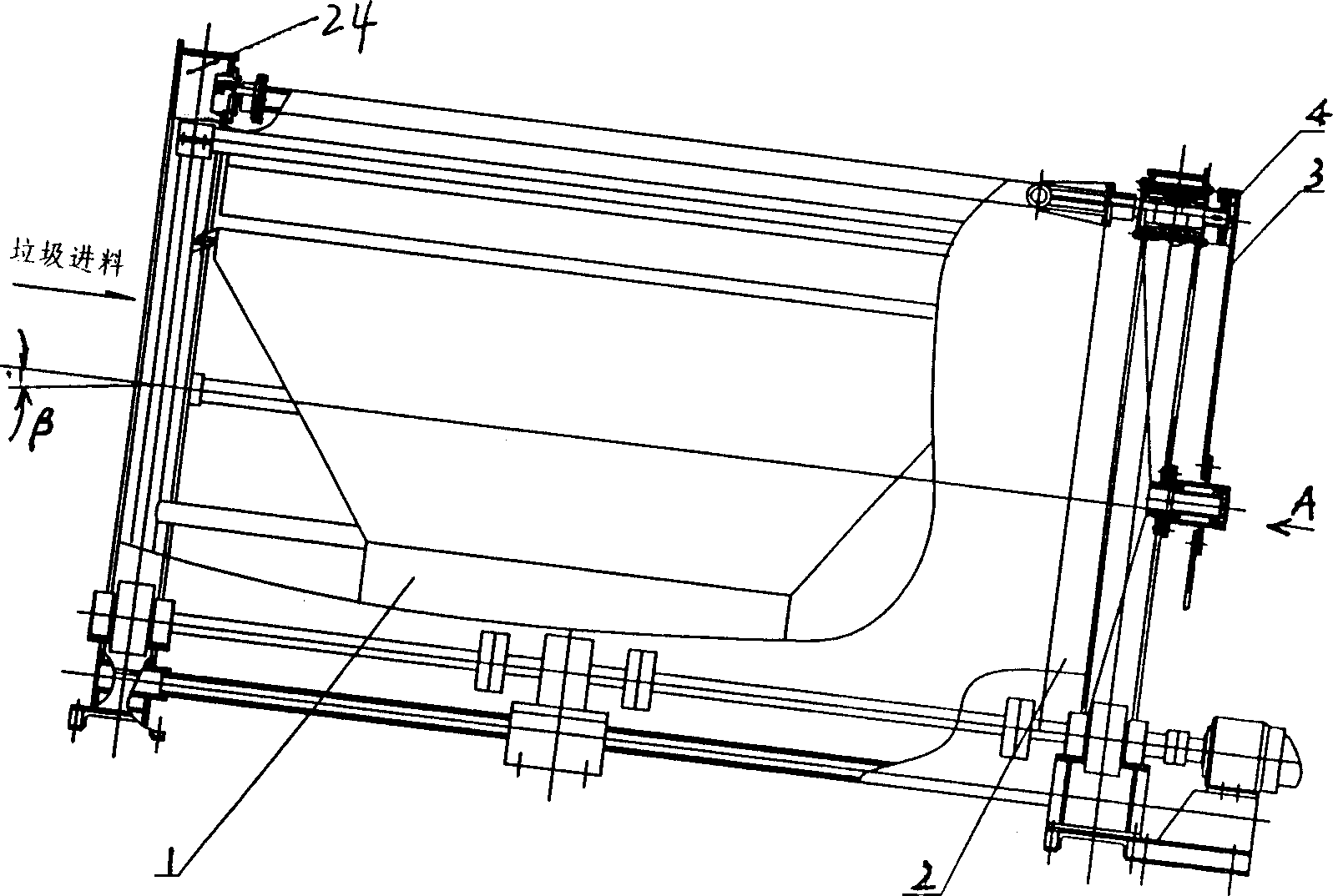

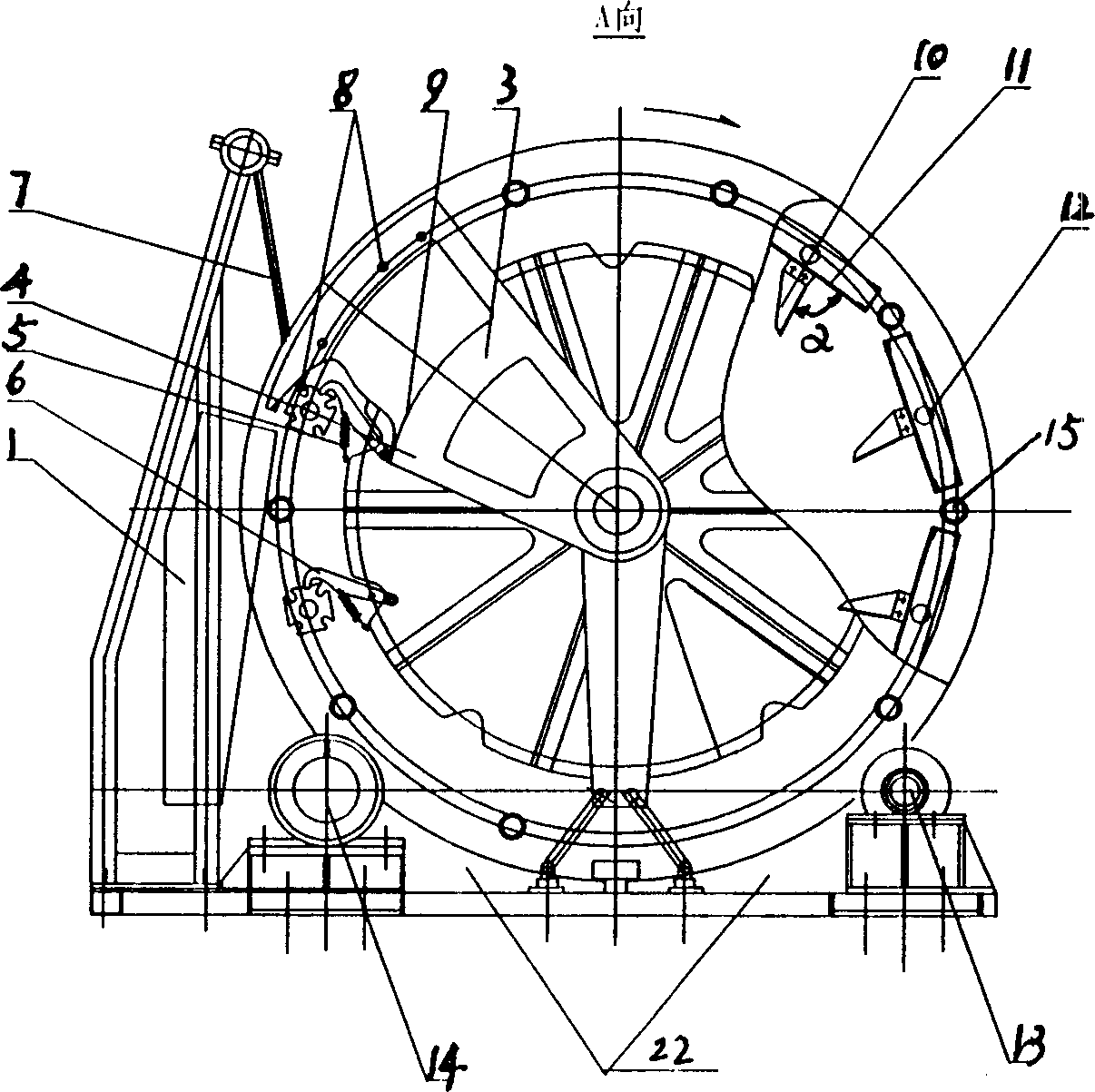

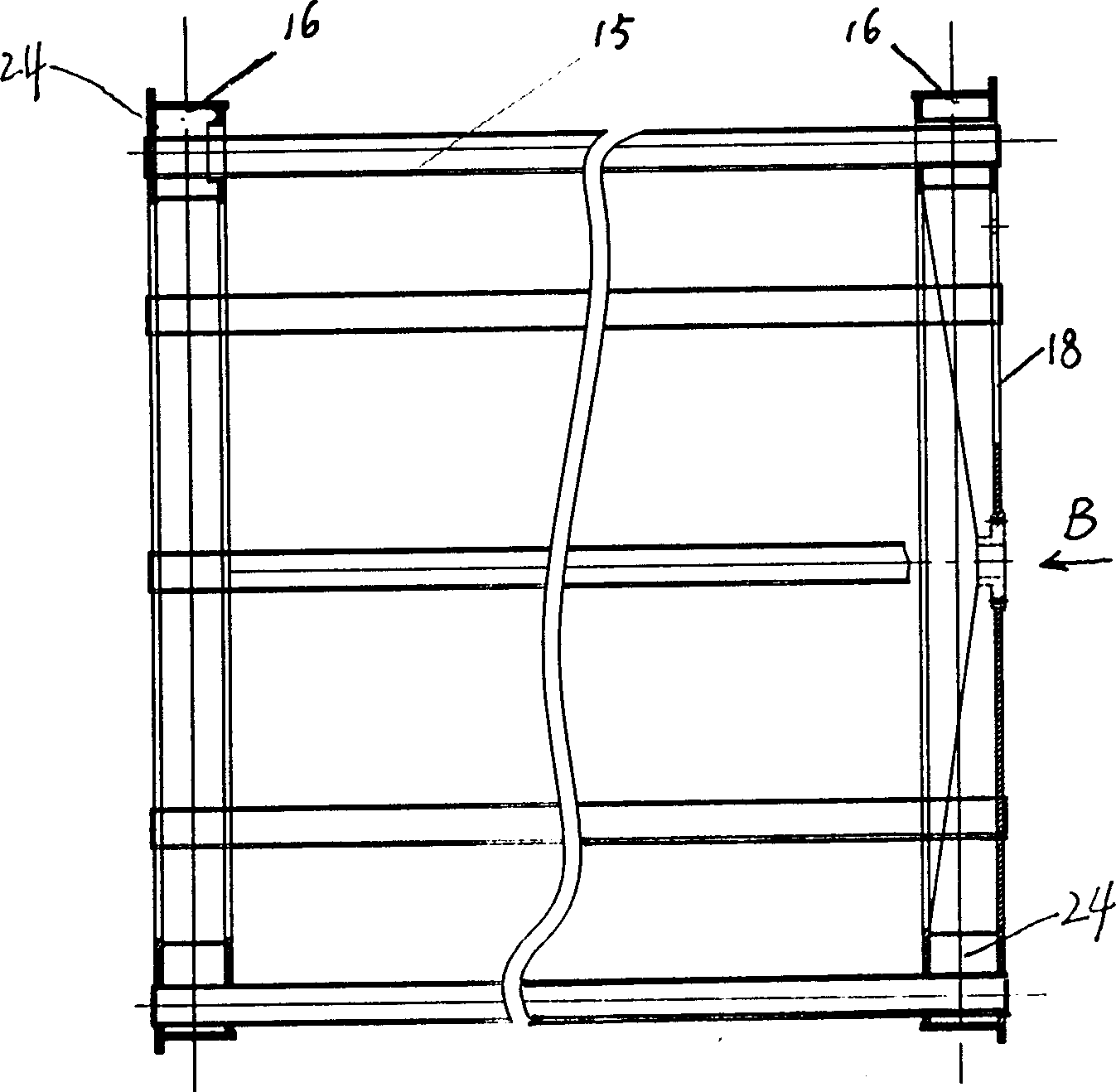

[0018] Screening machine of the present invention such as figure 1 — Figure 7 shown. The cylinder of the screening machine is a cage-shaped cylinder (such as image 3 shown). The frame of cage-shaped cylinder is made of cage bar 15 and the end frame 24 of its two ends, and end frame 24 has roller track 16 (as image 3 , Figure 4 shown). A sieve plate 11 is arranged between the cage bars 15 of the cage-shaped cylinder. Each sieve plate is rotated and assembled on the end frames 24 at both ends of the cage-shaped cylinder body through the rotating shaft 12 assembled on the respective longitudinal symmetry line, and the inner plate surface of each sieve plate 11 is uniformly fixed with an inward hanging body, and the hanging body is Pick up the hanging tooth cutter 10, the hanging surface of the hanging tooth cutter is provided with hanging teeth, the angle α of the tangent between the hanging surface and the direction of rotation of the cylinder is an acute angle (settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com