Joint for casing and casing connecting structure using said joint

A technology for connecting structures and casings, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of poor connection, troublesome connection of PC casings, and many times of spiral bonding and wrapping tape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below according to the accompanying drawings.

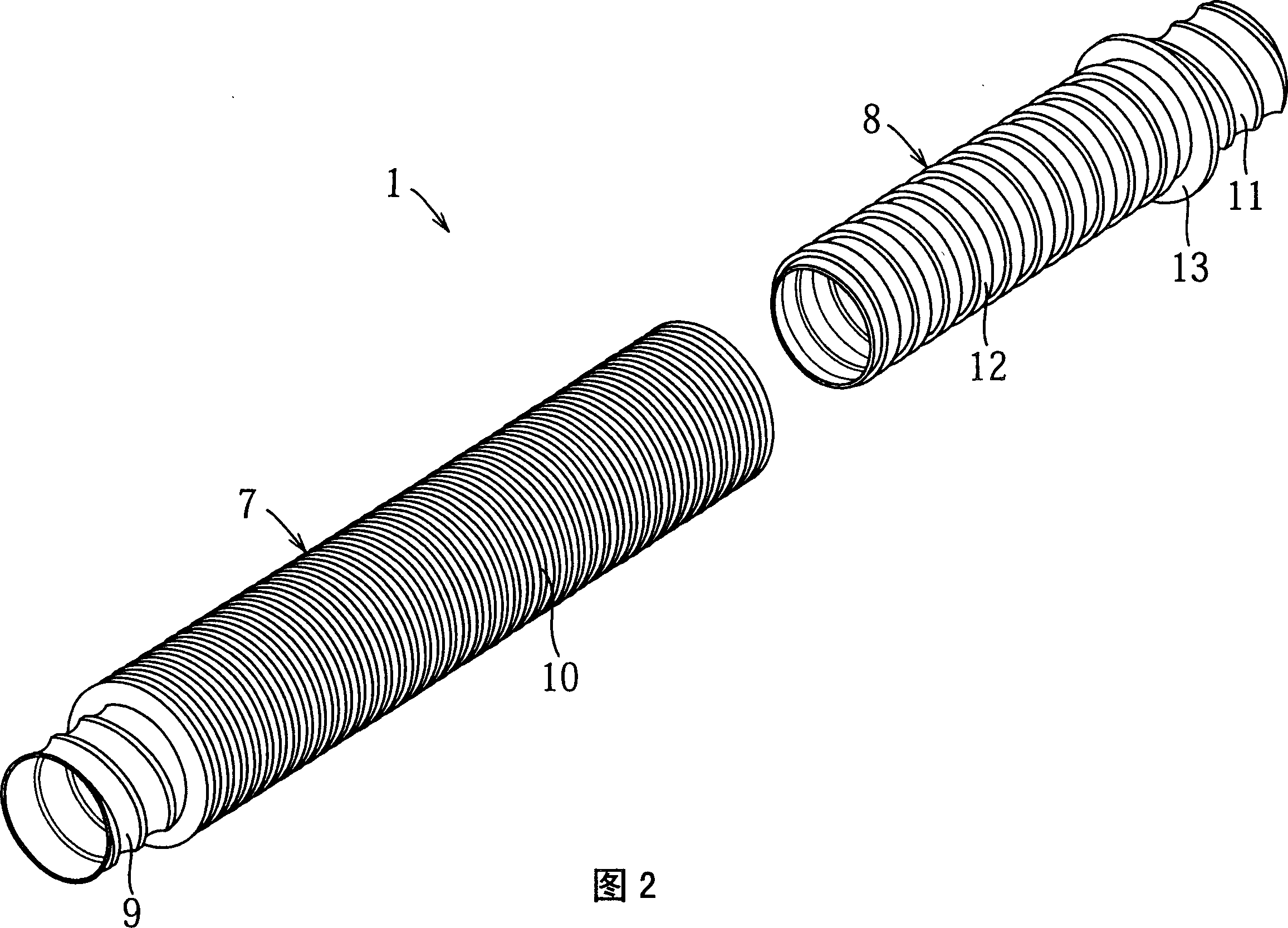

[0028] Such as Figure 4 As shown in the following figures, 1 is the gap filling part 6 arranged between the adjacent concrete bridge decks 2, 3 and connecting the PC casings 4, 5 for penetrating PC steel embedded in the concrete bridge decks 2, 3. Connectors for bushings. And the concrete bridge decks 2 and 3 are made of prefabricated concrete. The PC sleeve pipes 4 and 5 are helical corrugated pipes made of synthetic resin. In addition, the PC bushings 4, 5 are embedded in the plates 2, 3 so that their end surfaces substantially coincide with the end surfaces of the plates 2, 3. In addition, the width of the gap filling portion 6 is, for example, about 500 mm.

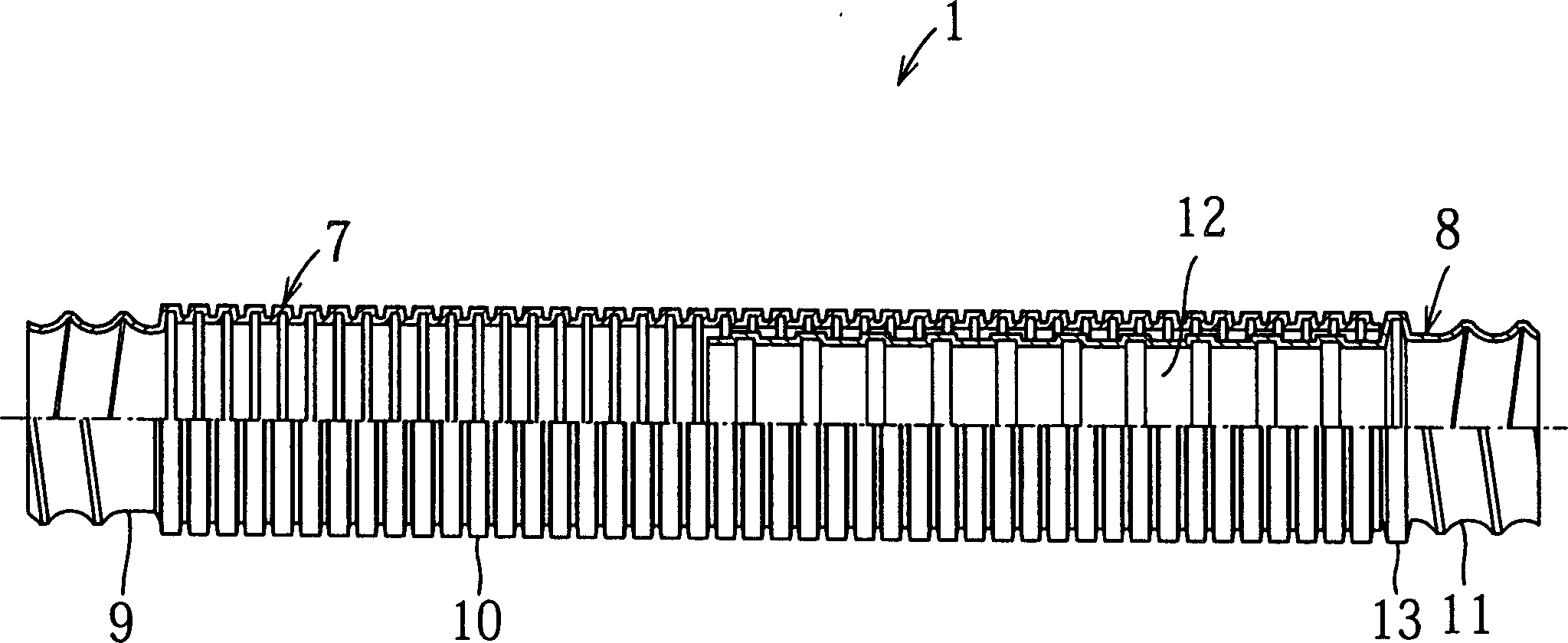

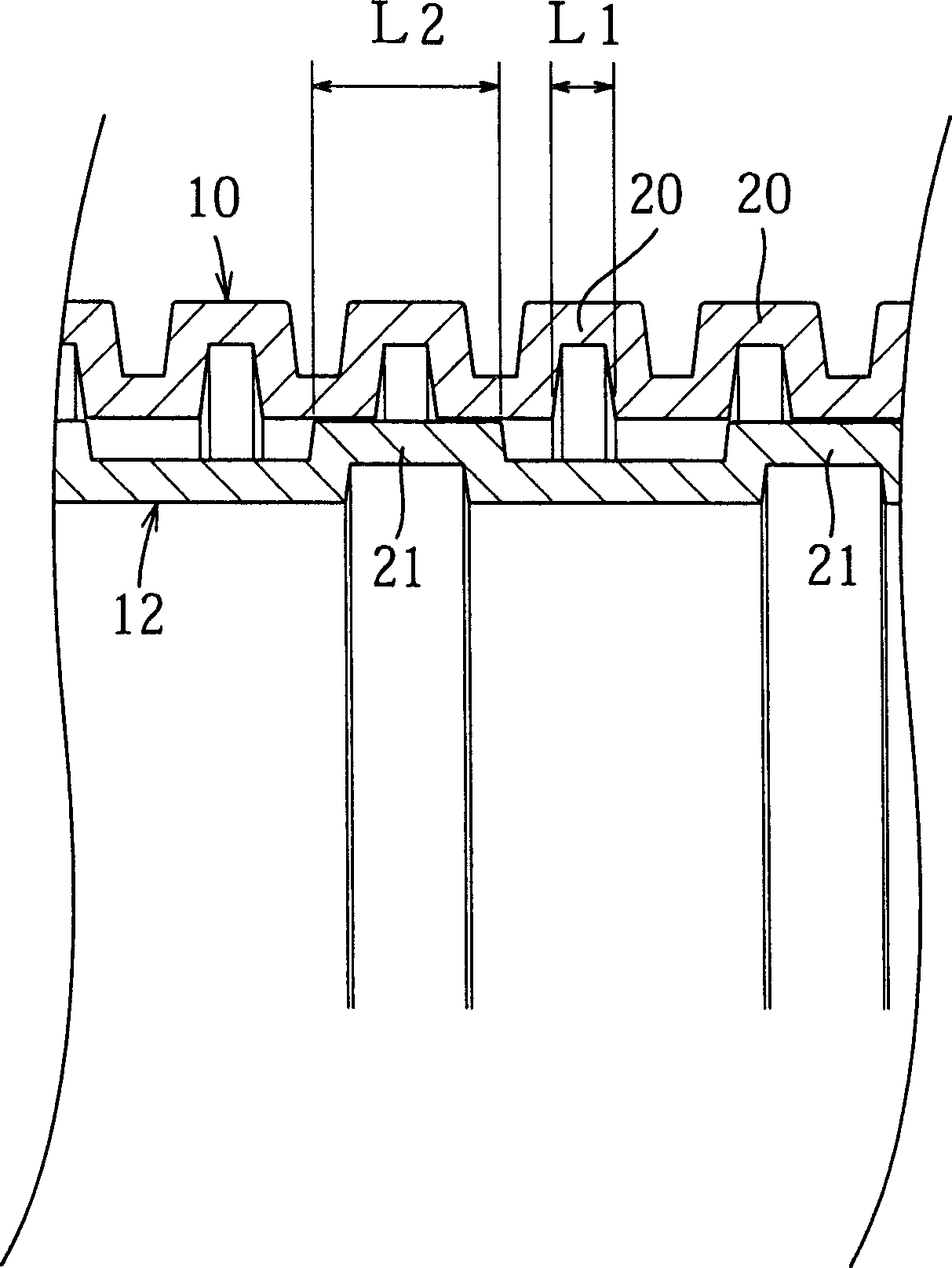

[0029] The casing joint 1 has a first connecting pipe, that is, an outer pipe 7, which is connected to the PC casing 4 on one side so as to be movable in the direction of the pipe axis, and is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com