Thermal treatment method of metal tube and said thermal treatment apparatus

A technology of heat treatment method and heat treatment device, applied in the direction of heat treatment furnace, heat treatment equipment, improvement of process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Although the implementation of the present invention may not consider the purpose and material of the metal cylinder, the main purpose of the cylinder is rolls and rotating shafts, and the main material can be carbon steel, low alloy steel, mold steel, high-speed steel or stainless steel. .

[0030] Here, first, an apparatus used for carrying out the present invention will be described.

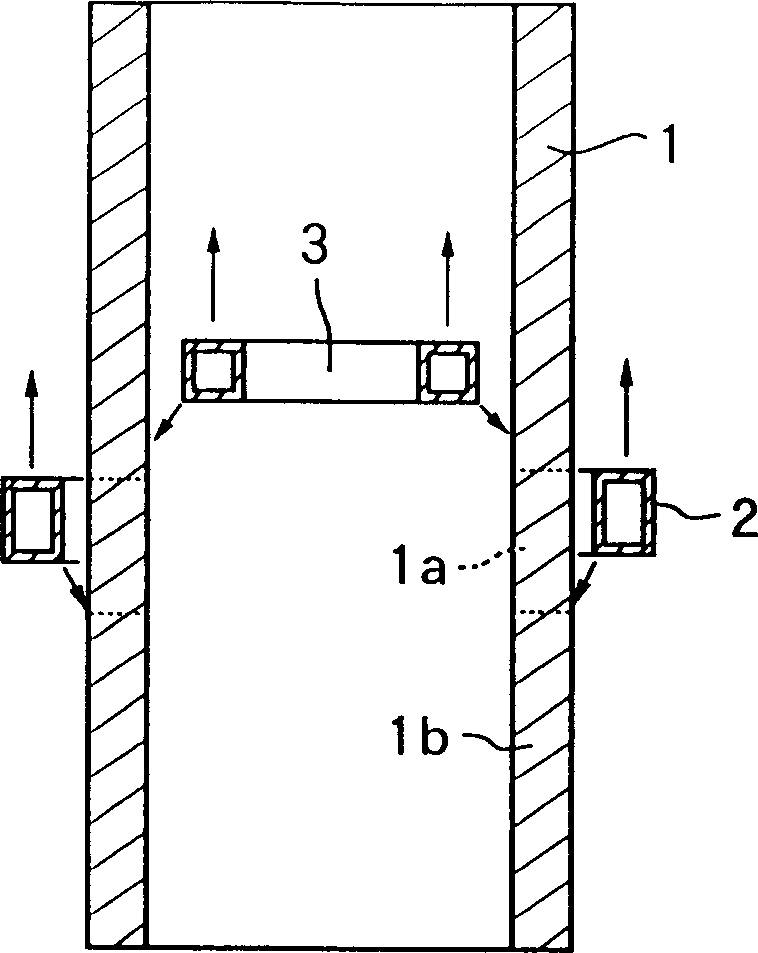

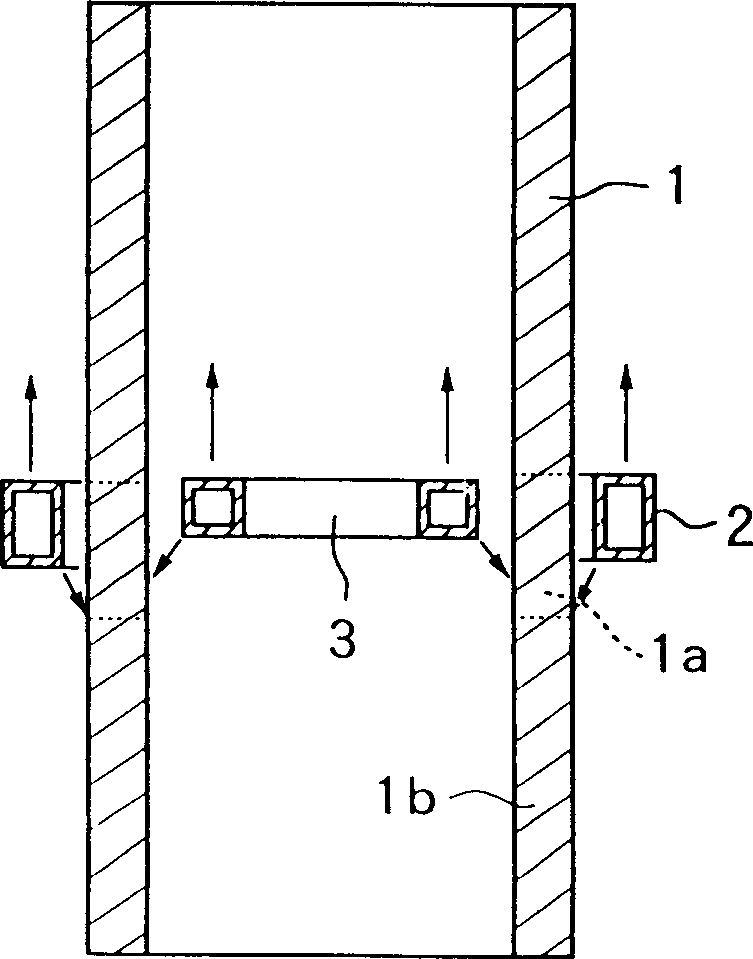

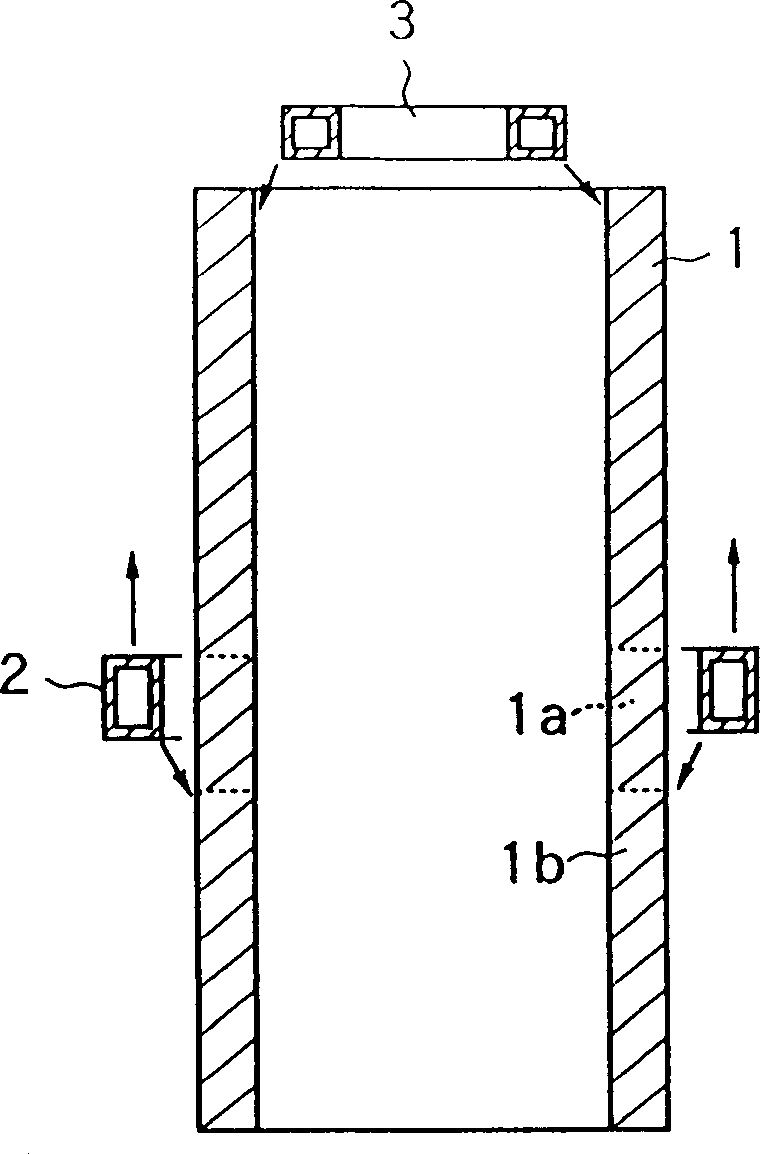

[0031] figure 1 Taking an example of the device for implementing the present invention as a model to show its front sectional view, on the outer surface side, the axial small area 1a of the metal cylinder 1 is inductively heated to the heat treatment temperature by the heating coil 2 surrounding it, and this heating operation is performed by The lower end of the cylindrical body is continuously advanced to the upper end. At the same time, the cooling device 2a that injects cooling water in the coil from the small hole group 2aa provided on the coil cools the rear end side adjacent ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com