Male and female connection plug convenient to understand internal corrosion condition

A technology of internal corrosion and plug connectors, which is applied in the direction of two-part connection devices, connections, electrical components, etc., can solve the problems of reduced electrical conductivity due to resistance, increased user electricity costs, and loose plug connectors, so as to avoid increased resistance, Avoid the effect of conductivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

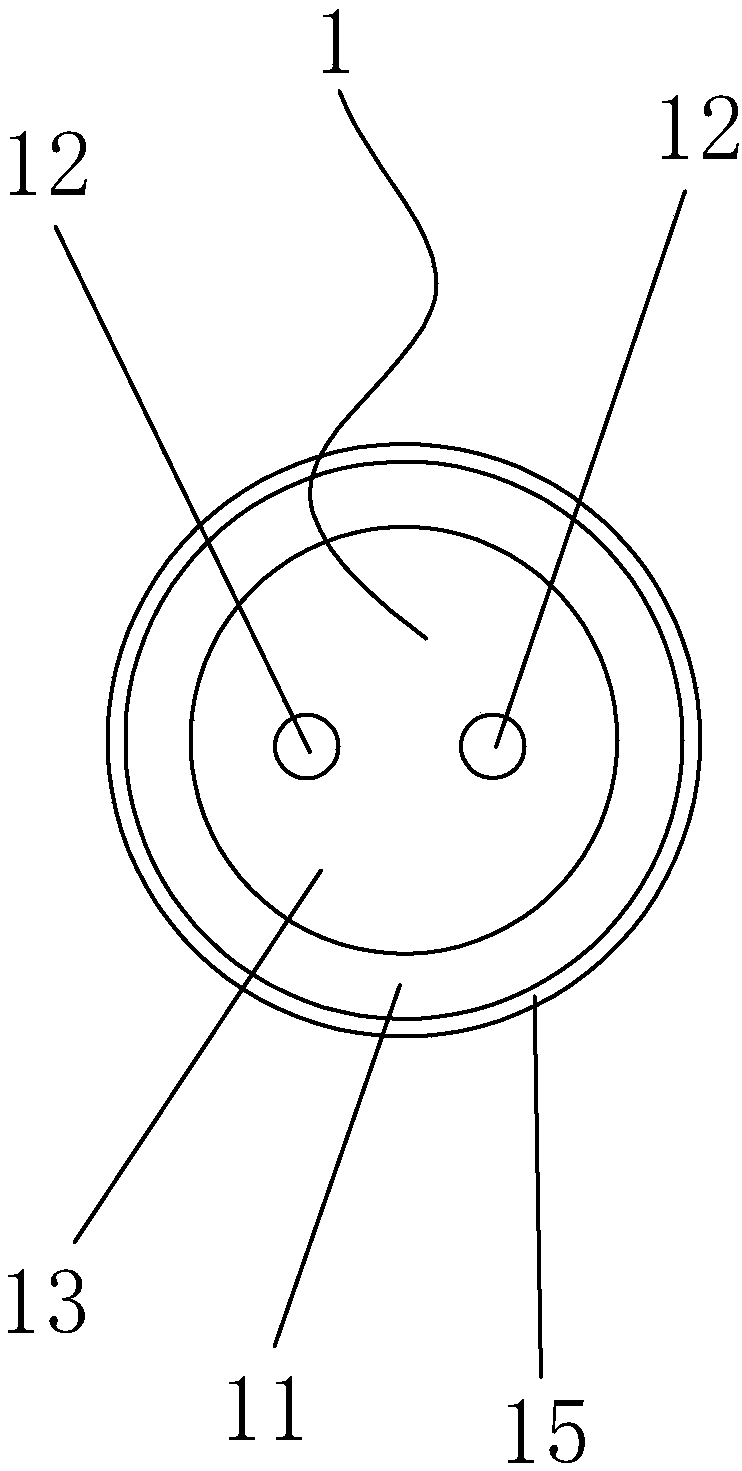

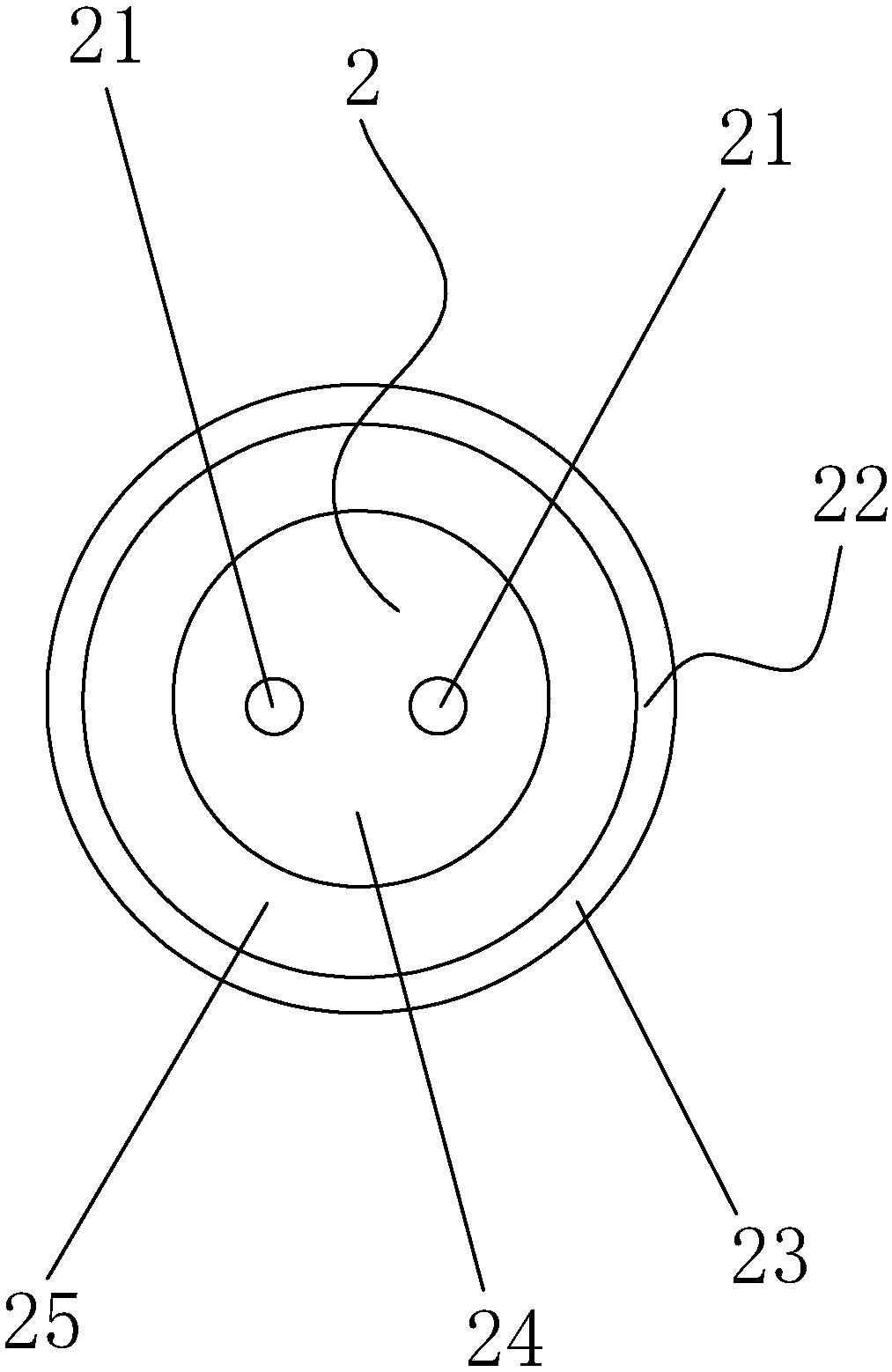

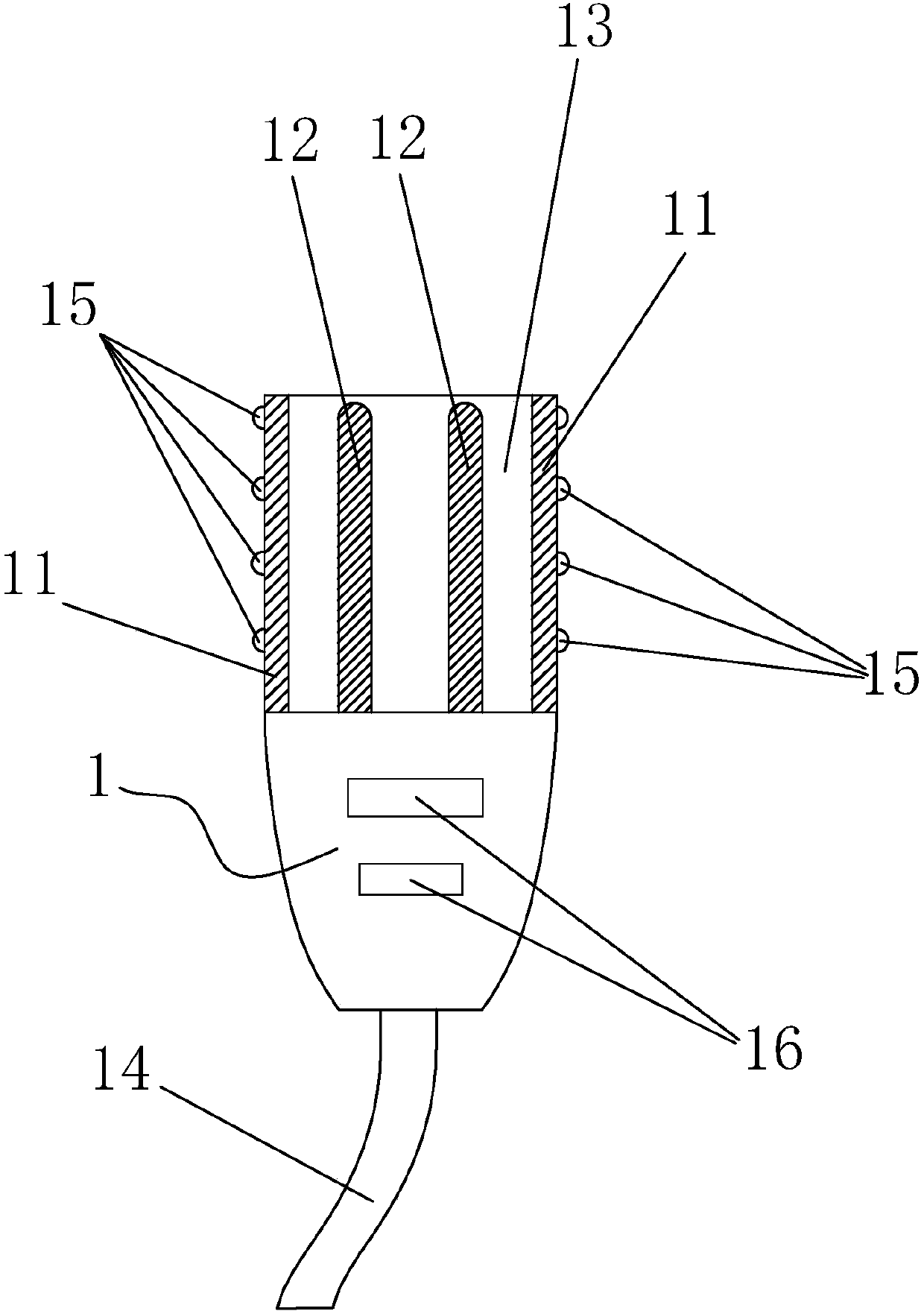

[0016] refer to Figure 1-Figure 4 , a male-female plug connector of the present invention that facilitates understanding of internal corrosion conditions, including a male plug connector 1 and a female plug connector 2 for mating and connecting with the male plug connector 1; the female plug connector 2 includes Based on the cylindrical electrode sheet 21 receiving power and the integrally formed transparent protective layer 22, the transparent protective layer 22 includes a transparent outer layer 23 and a transparent inner layer 24 for wrapping the cylindrical electrode sheet 21, between the transparent outer layer 23 and the transparent inner layer 24 There is a female connection cavity 25 for plugging in with the male plug connector 1; the male plug connector 1 includes an integrally formed transparent shell 11 and electrode terminals 12 for transmitting power, and the inside of the transparent shell 11 is provided with an end The open male connection cavity 13, the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com