Nanolizing method for metal material surface

A metal material and nanotechnology, which is applied in the field of solid-liquid two-phase jet impacting the surface of metal materials, can solve the problems of processing, metal parts and large-plane metal equipment that cannot be nano-sized, and achieve low energy consumption and low cost. The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1

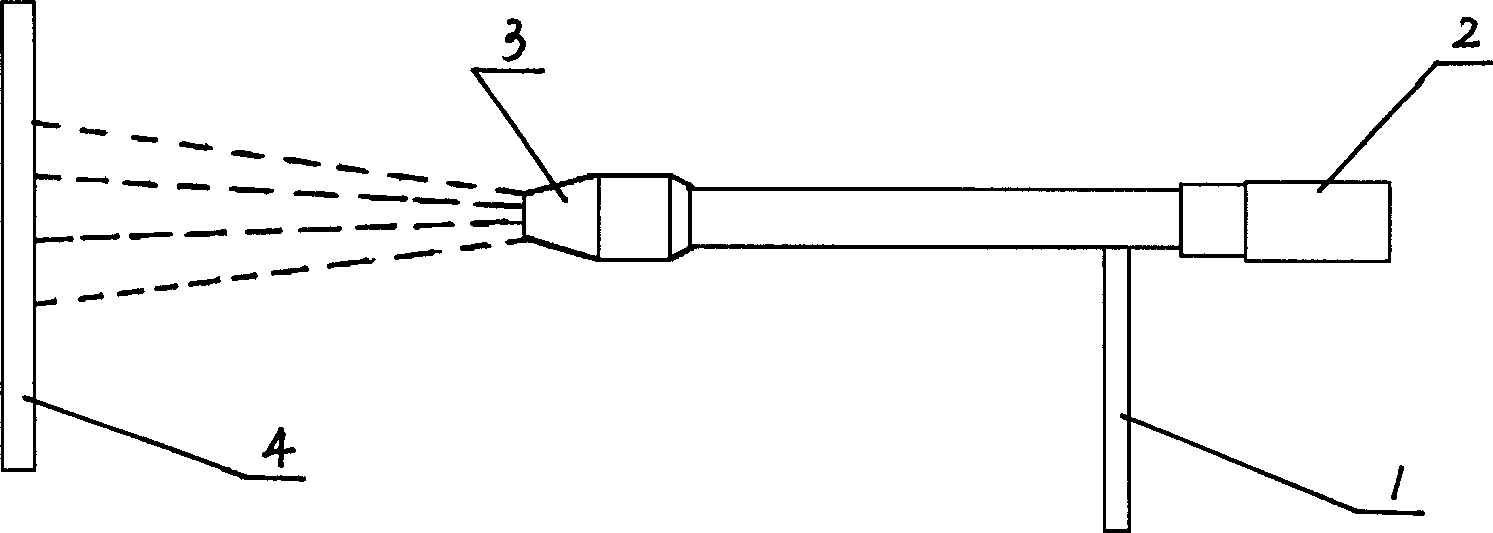

[0024] The surface nanometerization device adopts Kranzle high-pressure cleaner 3250TST or 3270TST from Shanghai Hanover Trade Development Co., Ltd., such as figure 1 As shown, the solid phase tube 1 and the liquid phase tube 2 are joined to the nozzle 3, the solid phase tube 1 is connected to the pill feeder, and the liquid phase tube 2 is connected to the high-pressure water generator. The engine power is 7.5KW, and the base material is 316L. Stainless steel test piece, hard particles are made of Al 2 O 3 (Around 500 microns);

[0025] The high-pressure water generated by the high-pressure water generator is used to generate a solid-liquid two-phase jet through the nozzle 3 to carry hard particles (spherical) to continuously bombard the surface of the matrix material 4 at a speed of 700 m / s to make it nanometer. The surface nanometerization process parameters are as follows:

[0026] The spraying distance is 500mm, the water pressure is 22MPa, the water flow ...

Example Embodiment

[0027] Example 2

[0028] The difference from Example 1 is:

[0029] The particles are made of steel balls (0.5~1mm), and the process parameters are as follows:

[0030] The spraying distance is 300mm, the water pressure is 25MPa, the water flow is 15 l / min, the solid-liquid dual-phase jet velocity is 750m / s, and the bombardment time is 4 minutes. The nanophase is formed on the surface observed by transmission electron microscope. The TEM bright field image after sample treatment, dark See the field image and diffraction ring separately Figure 5 , 6 , 7.

Example Embodiment

[0031] Example 3

[0032] Difference from Example 1:

[0033] The base material is 20# steel test piece, the particles are steel balls (about 4mm), and the process parameters are as follows:

[0034] The spraying distance is 800mm, the water pressure is 30MPa, the water flow is 11 l / min, the solid-liquid dual-phase jet velocity is 900m / s, and the bombardment time is 4 minutes. The nanophase is formed on the surface observed by transmission electron microscope. The TEM bright field image after sample treatment, dark See the field image and diffraction ring separately Figure 8 , 9 , 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com