Liqufied gas steel cylinder having sealing marker

A technology of liquefied gas and steel cylinders, which is applied in the direction of container discharge, gas/liquid distribution and storage, and container filling methods, and can solve problems such as conflicts between manufacturers and users, leakage of interests, safety, and illegal release of liquefied gas. Simple, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

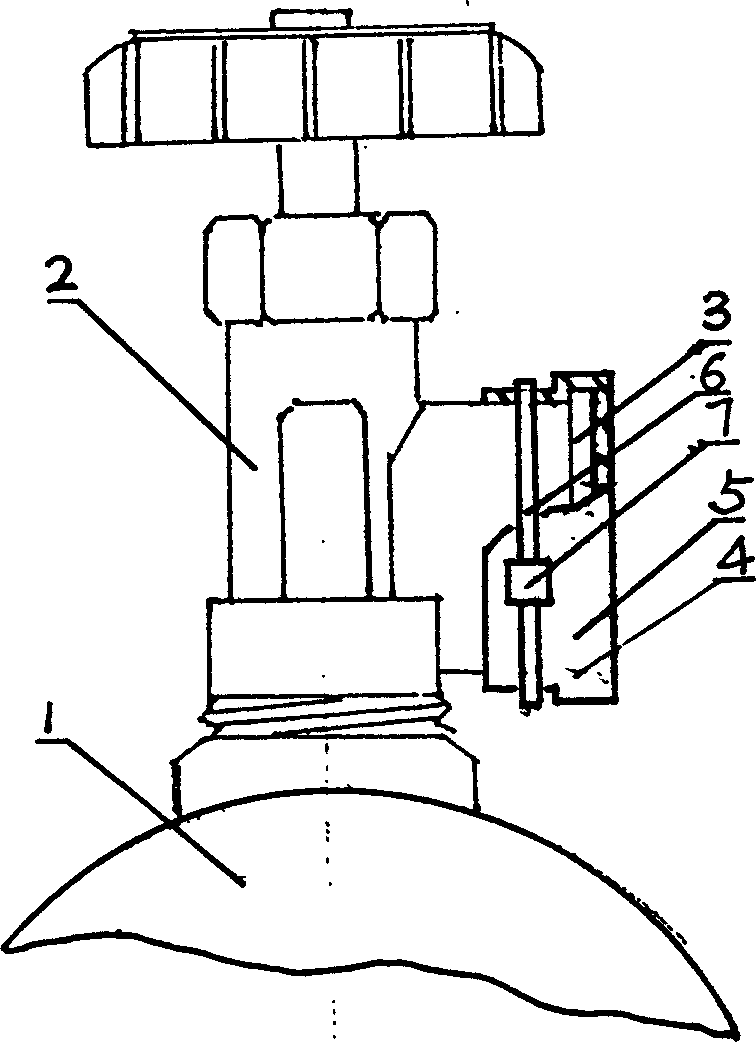

[0012] The steel cylinder of the present invention is composed of a bottle body 1, an angle valve 2 and a bottle mouth 3. A seal 4 is installed at the bottle mouth 3. The seal 4 is composed of a wrapping piece 5 and a pull ring 6. Sheet 5 and wrapping sheet 5 are soft sheet materials, and the outer side of wrapping sheet 5 has annular pull ring 6 along the outer peripheral wall of bottle mouth 3, and check seal 7 is arranged at the joint of pull ring 6, see figure 1 .

example 2

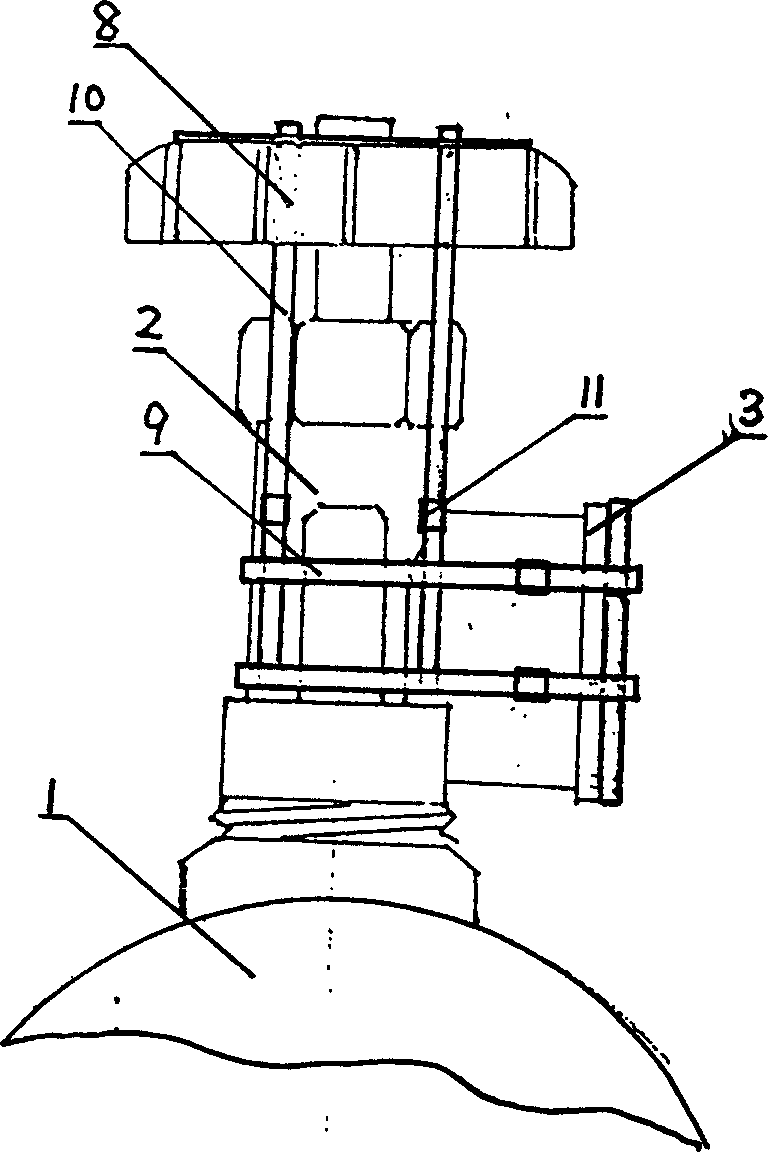

[0014] A sealing label 4 is installed at the bottle mouth 3, and there is a horizontal tension rib 9 around the bottleneck and the sealing label 4, and there is a longitudinal tension rib 10 between the horizontal tension rib 9 and the hand wheel 8, and at the joint of the horizontal tension rib 9 and the longitudinal tension rib 10 Lead seals 11 are installed respectively, and the seal 4 can be a sheet, the shape is the same as the outer edge of the bottle mouth 3, and it is attached to the bottle mouth 3, and the seal 4 can also be a pipe plug, which is installed on the bottle mouth within 3. See figure 2 .

example 3

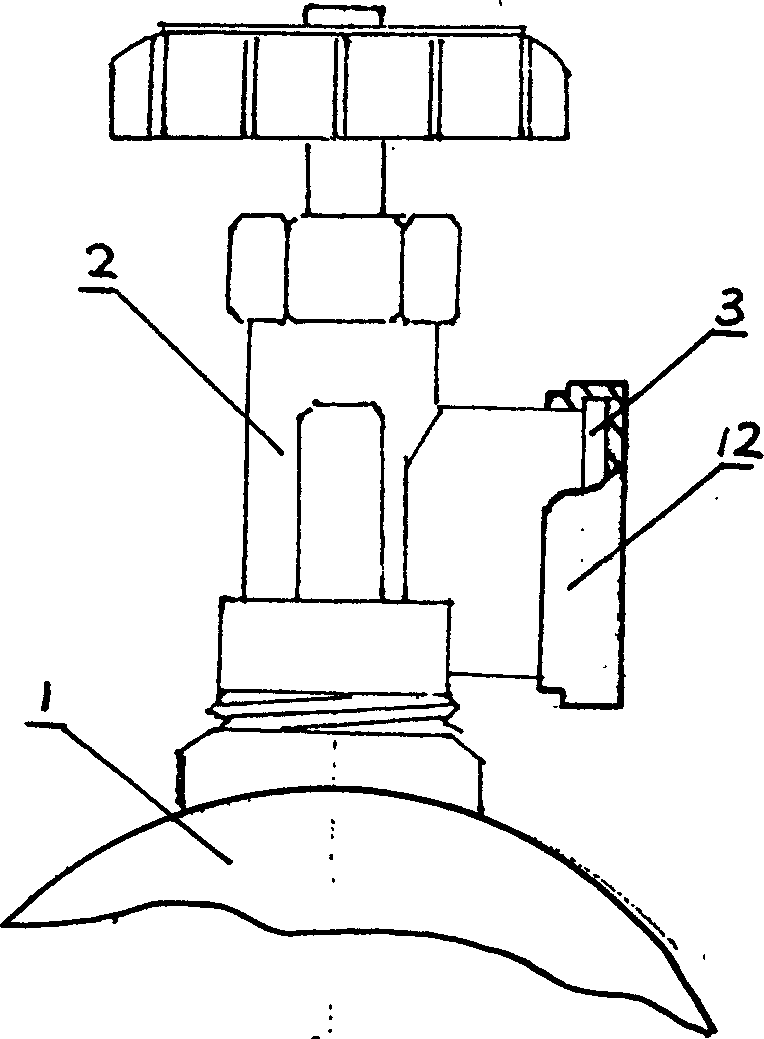

[0016] Gland 12 is equipped with as sealing label (4) at bottleneck 3 places, and the axial section of gland 12 is boss shape, and correspondingly cooperates with the peripheral wall shape of bottleneck 3 places, and gland 12 surrounds bottleneck 3. The gland 12 is similar to the bottle caps of injection medicines such as penicillin. After the manufacturer canned liquefied gas, the gland 12 is pressed on the bottle mouth 3, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com