Process and apparatus for coal-charging and tamping synchronizing cycle operation into horizontal coking furnace

A cycle operation and coking oven technology, applied in coking ovens, petroleum industry, charging devices, etc., can solve the problem of prolonging the tamping coal-coal charging operation cycle, reducing equipment utilization, and being unable to distribute coal and tamping briquettes and other problems, to achieve the effect of shortening the coal loading operation cycle, improving the utilization rate, and making full use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

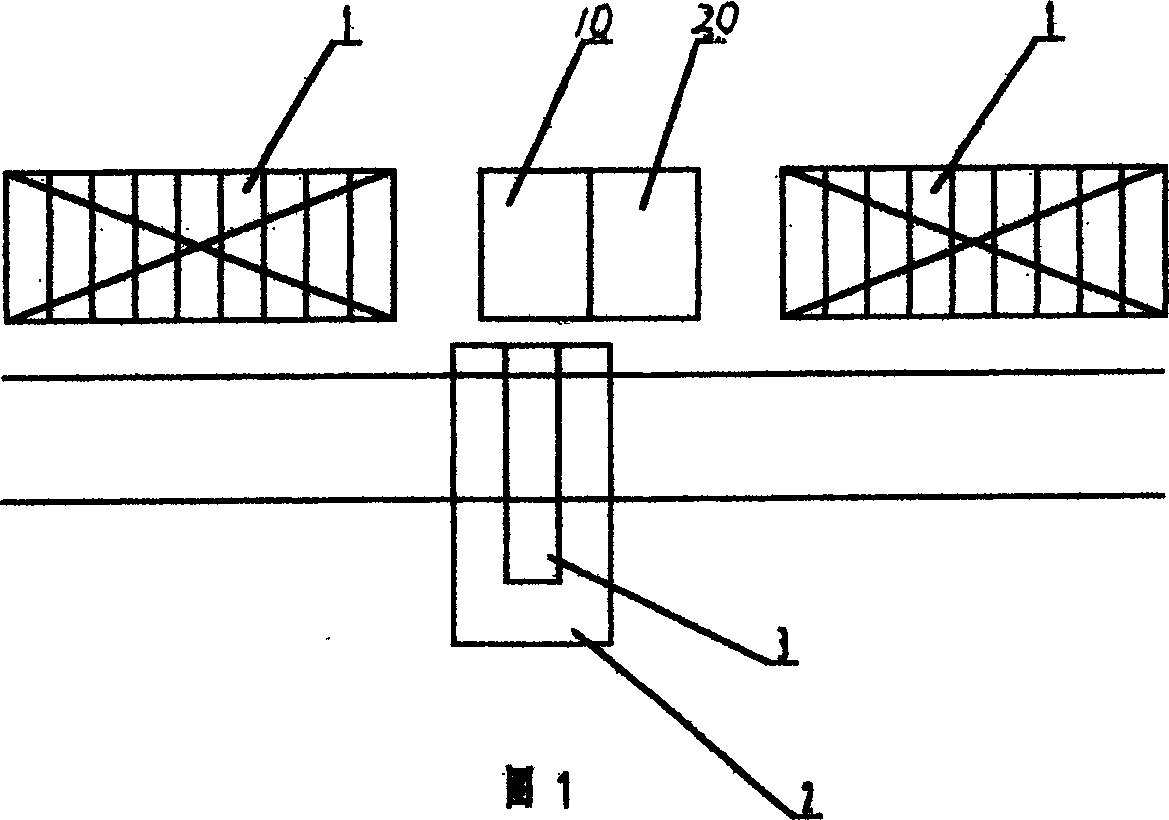

[0027] Figure 1, image 3 Shown, a kind of method for synchronous cycle operation of charging coal and tamping coal in the horizontal coke oven, its steps are:

[0028] 1) The coal loading car 2 runs from the front track of the horizontal coke oven 1 to the A tamping platform 10 where the coal is to be tamped. image 3 (a);

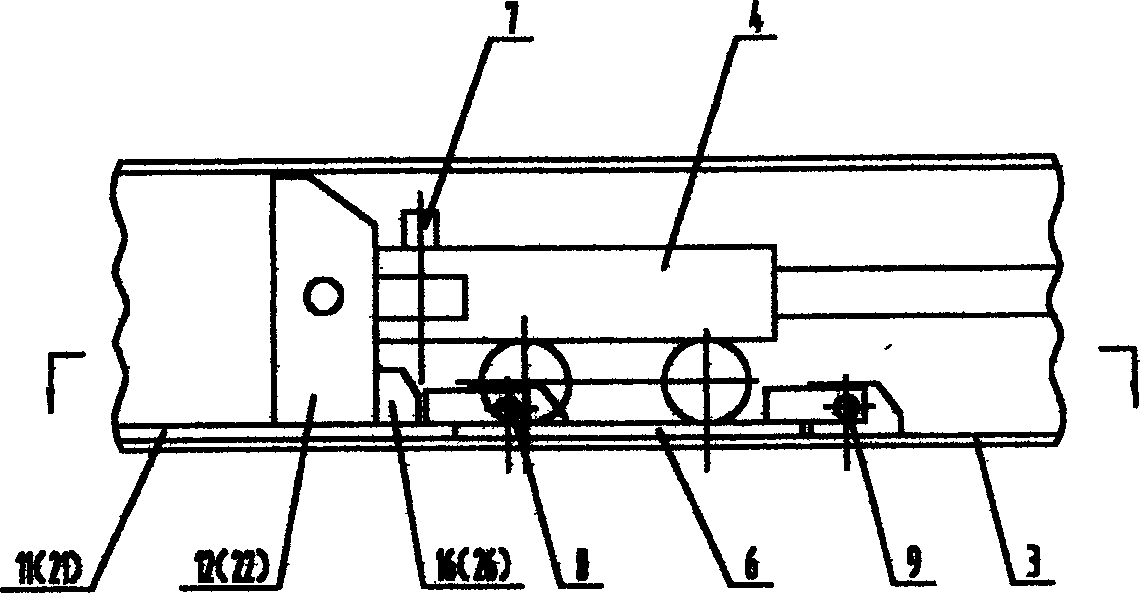

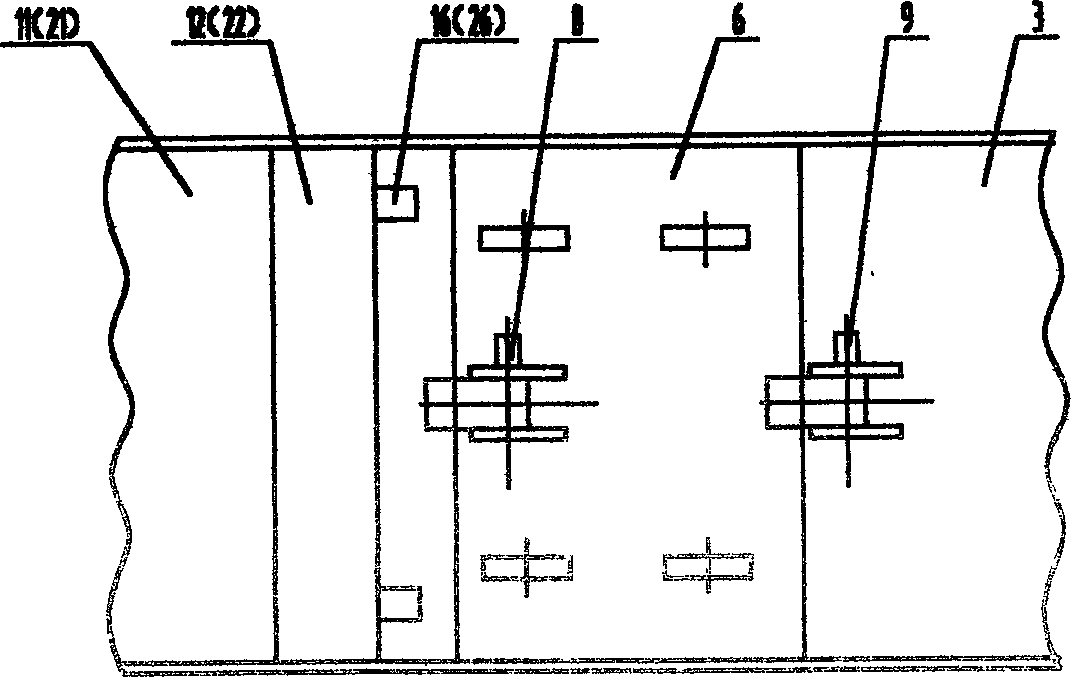

[0029] 2) Disengage the locking of the A coal support plate 11 and the box-shaped coal drum 3 of the coal loading car 2, and the A coal support plate 11 together with the A coal retaining plate 12 and the ejector head 4 of the coal loading car 2, from the coal loading car 2 The coal drum 3 is dragged to the A tamping platform 10 by the traction mechanism 15, as image 3 (b);

[0030] 3) Close the A side formwork 14 arranged on both sides of the A coal support plate 11 on the A tamping platform 10, and lock with the end formwork 12, 13 at both ends, wherein the end formwork 12 is the A coal retaining plate of the coal loading car;

[0031] 4) Disengage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com