A kind of lithium-ion battery forming method

A lithium ion battery and a technology of a chemical formation method are applied in the field of lithium ion battery preparation, and can solve the problems such as the inability to fully utilize the capacity of the lithium ion battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

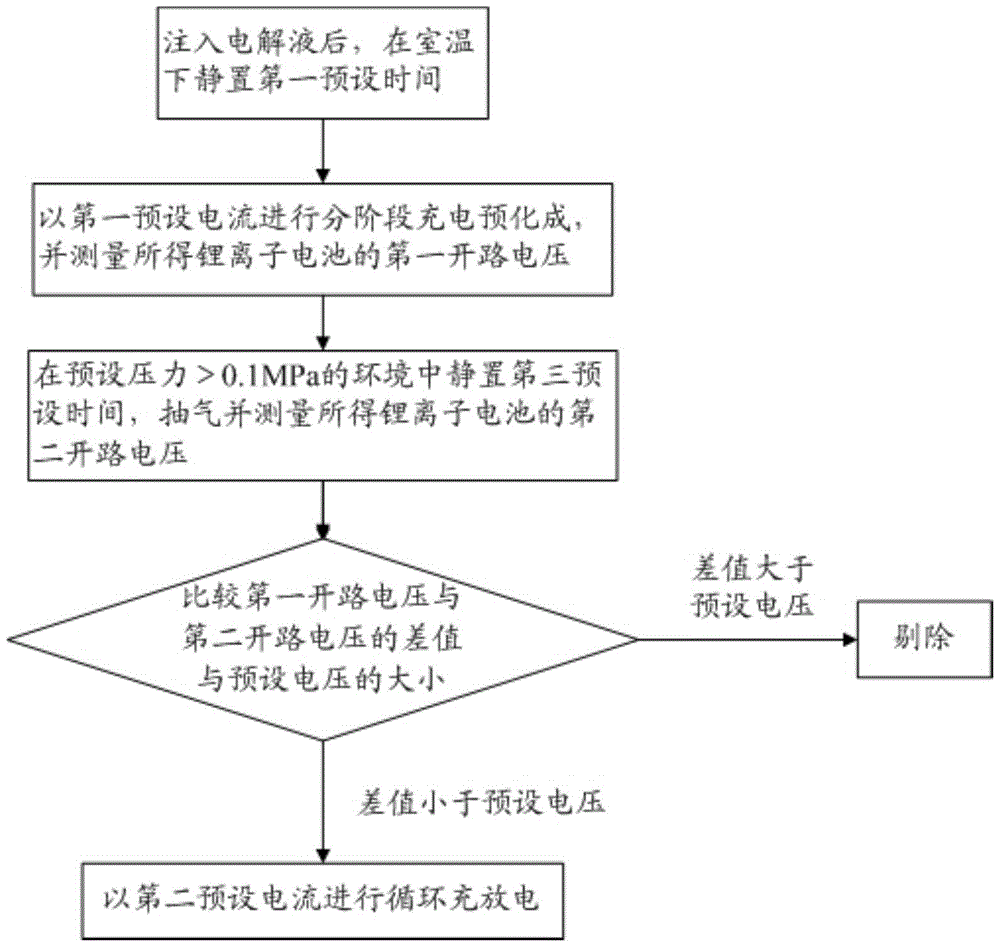

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for forming a 633448 type soft-packed square lithium iron phosphate battery. The specific steps are as follows:

[0045] Step 1, inject electrolyte solution into the rolled and dried 633448 soft-packed square lithium iron phosphate battery, and then let it stand at room temperature for 48 hours;

[0046] Step 2, use a current of 90mA (ie 0.1C) to charge and preform the lithium iron phosphate battery obtained in step 1 in stages, and charge it with a capacity of 0.135Ah (ie 15% SOC), and let it stand for 10min until it is charged to 0.45Ah (i.e. 50% SOC); the first open circuit voltage U1 of the lithium iron phosphate battery after pre-forming is 3.19V;

[0047] Step 3, place the lithium iron phosphate battery obtained in step 2 in a high-pressure environment with a pressure of 1 MPa and let it stand for 24 hours; then take the battery out of the high-pressure environment and pump air, and the second open circuit voltage U2 of the batter...

Embodiment 2

[0051] This embodiment provides a method for forming a 633448 type soft-packed square lithium iron phosphate battery. The specific steps are as follows:

[0052] Step 1, inject electrolyte solution into the rolled and dried 633448 soft-packed square lithium iron phosphate battery, and then let it stand at room temperature for 24 hours;

[0053] Step 2, use a current of 45mA (that is, 0.05C) to charge and preform the lithium iron phosphate battery obtained in step 1 in stages, and charge it with a capacity of 0.135Ah (that is, 15% SOC), and let it stand for 10 minutes until it is charged to 0.27Ah (i.e. 30% SOC); the first open circuit voltage U1 of the lithium iron phosphate battery after pre-forming is 3.19V;

[0054] Step 3, place the lithium iron phosphate battery obtained in step 2 in a high-pressure environment with a pressure of 0.5 MPa and let it stand for 12 hours; then take the battery out of the high-pressure environment and pump air, and the second open circuit volt...

Embodiment 3

[0058] This embodiment provides a method for forming a 633448 type soft-packed square lithium iron phosphate battery. The specific steps are as follows:

[0059] Step 1, inject electrolyte solution into the rolled and dried 633448 soft-packed square lithium iron phosphate battery, and then let it stand at room temperature for 50 hours;

[0060] Step 2, use a current of 180mA (ie 0.2C) to charge and preform the lithium iron phosphate battery obtained in step 1 in stages, and charge it with a capacity of 0.135Ah (ie 15% SOC), and let it stand for 10 minutes until it is charged to 0.63Ah (i.e. 70% SOC); the first open circuit voltage U1 of the lithium iron phosphate battery after pre-forming is 3.21V;

[0061] Step 3, placing the lithium iron phosphate battery obtained in step 2 in a high-pressure environment with a pressure of 0.8 MPa and standing for 18 hours; then taking the battery out of the high-pressure environment and pumping air, at this time, the second open circuit vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com