Process and apparatus for expanding multi-stage axial flow gas compressor stable operation zone

An axial flow compressor, stable operation technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve catastrophic accidents, reduce unit operating efficiency, affect system stable operation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the present invention more clearly, this embodiment takes a four-stage axial flow compressor as an example.

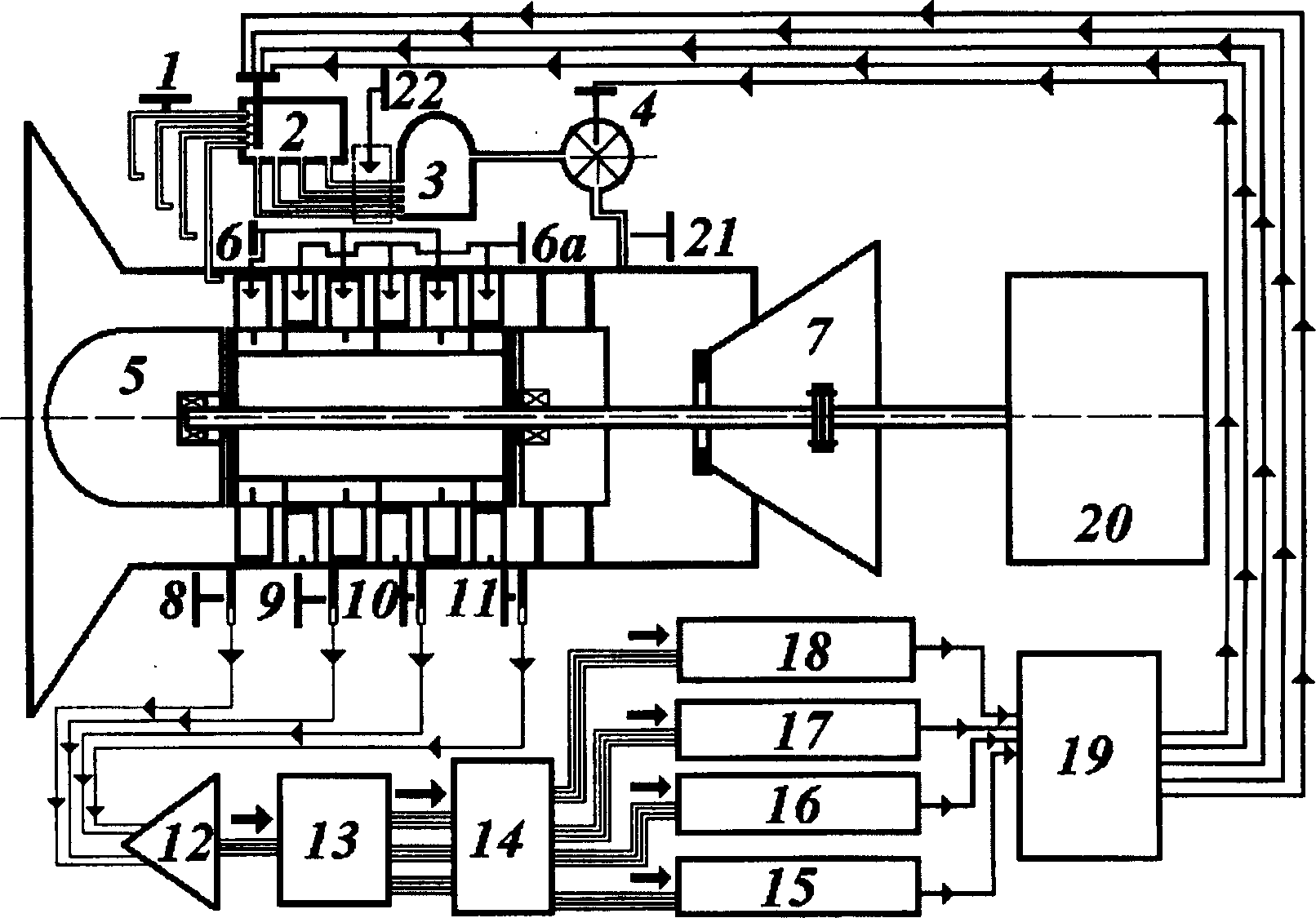

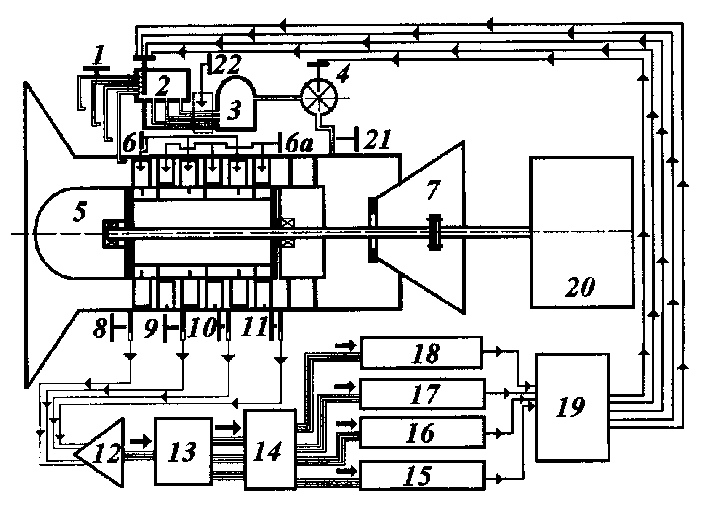

[0036] like figure 1 , 2 As shown, powered by the motor 20, the four-stage axial flow compressor 5 inhales gas, the gas flowing through the moving blade 6 and the stationary blade 6a is compressed, and the flow and pressure of the gas is controlled by the air outlet regulating valve 7 .

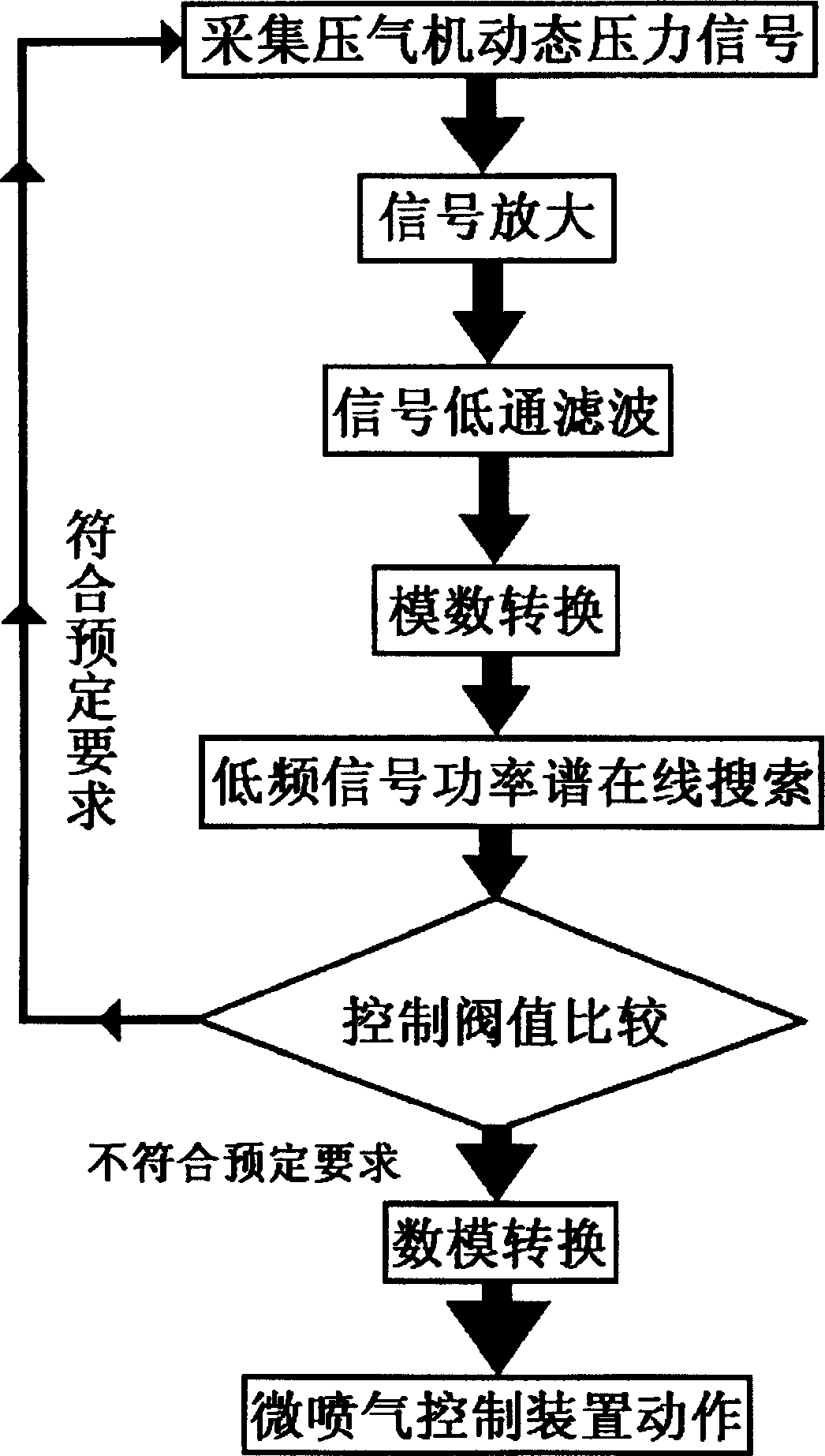

[0037] Four high-frequency response dynamic pressure sensors 8, 9, 10, 11 are used to collect dynamic pressure signals during compressor operation. Installed on the casing at the trailing edge of the stator vane of the last stage; then the signals are respectively sent to a pre-signal amplifier 12 to simulate and amplify the collected dynamic signals, and the gain of the amplifier is selected to be the highest pressure when the compressor is running stably The value is the upper limit, and the upper limit value is selected on the order of 4.5 volts; then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com