Air intake arrangement of isolating chamber

A technology of vacuum isolation chamber and air intake structure, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of affecting the quality of the wafer, easy to generate turbulence, and increase the ventilation time, so as to improve the output and pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

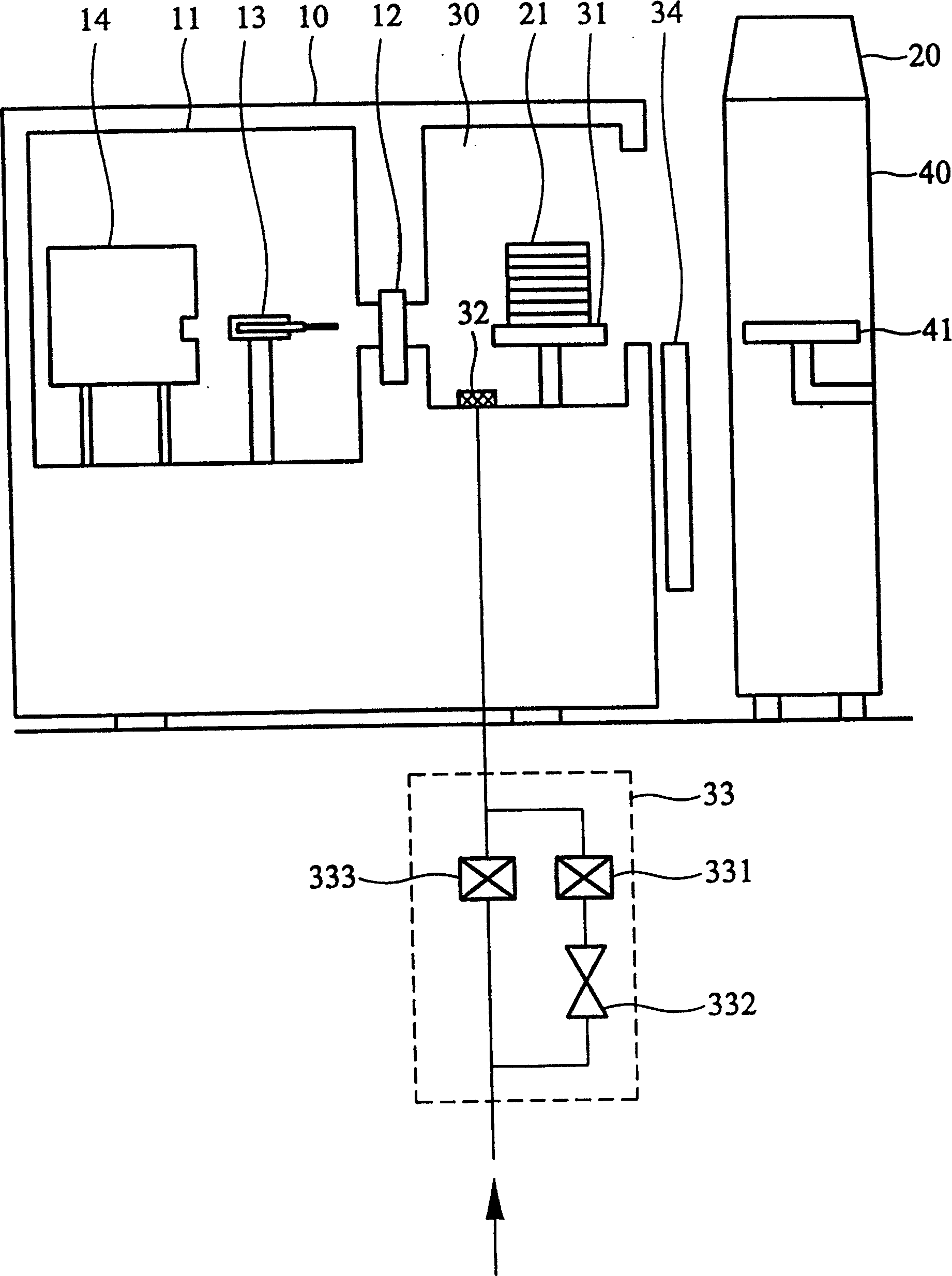

[0028] Figure 4 It is a schematic diagram of the ventilation device for the vacuum isolation chamber 30 of the semiconductor machine according to the embodiment of the present invention. Such as Figure 4 As shown, in the wafer factory, the wafer boat 20 is placed on the SMIF interface 40 by the on-line staff or the unmanned transport vehicle, and the wafer 21 is transferred from the wafer boat 20 to the semiconductor machine 10 by the robot arm of the SMIF interface 40 In the vacuum isolation chamber 30 of the vacuum isolation chamber 30, the dodge door 34 is closed and the vacuum isolation chamber 30 is airtight at this moment. Since semiconductor equipment must be in a vacuum state when producing wafers, the vacuum isolation chamber 30 must be continuously switched between vacuum and atmospheric pressure. In the embodiment of the present invention, the original gas flow controller is changed to a new control valve 50, and only a single vent valve 51 is used to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com