Flow control valve

A technology of flow control valve and fluid flow, applied in flow control without auxiliary power, safety valve, balance valve, etc., can solve the problems of complex mechanism, complex manufacturing method, lack of repeatability, etc., and achieve the effect of simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

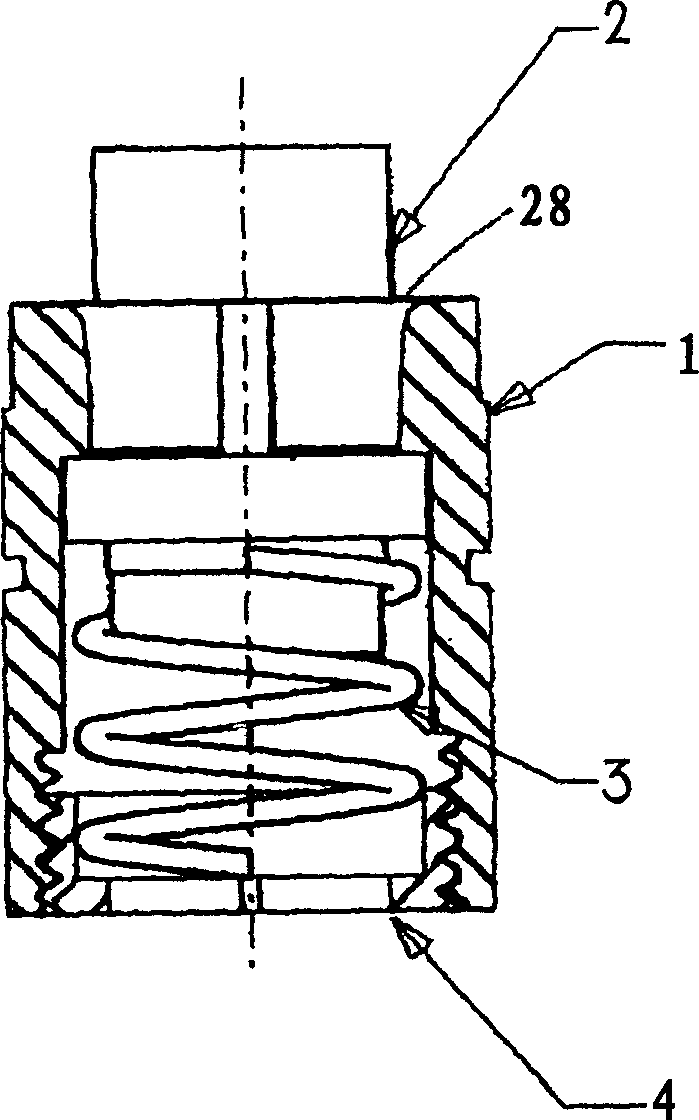

[0036] The constant flow valve is formed in the form of a cartridge which, in use, is mounted within a housing (not shown). The valve comprises a body part 1 , a piston part 2 , a compression spring 3 and a bottom ring 4 . The dimensions of these components can be varied to provide different predetermined fluid flow rates, and the housing can be fitted with a range of different cartridges depending on the required flow rates.

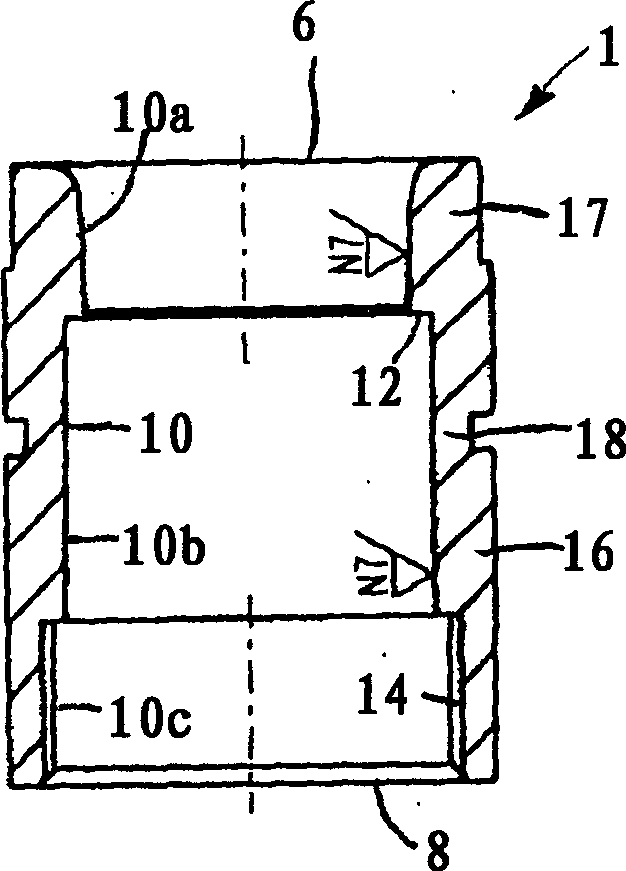

[0037] The main body 1 is substantially cylindrical with an inlet end 6 and an outlet end 8 . An axial bore 10 defining a fluid flow passage extends longitudinally through the body, the bore comprising an upper portion 10a, a middle portion 10b and a lower portion 10c.

[0038] The diameter of the upper part 10 a of the hole is non-uniform, increasing towards the inlet end 6 . The upper portion is flared or flared, and in the embodiment shown its diameter increases from about 13 mm at the lower end to about 15 mm at the inlet end. The shape of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com