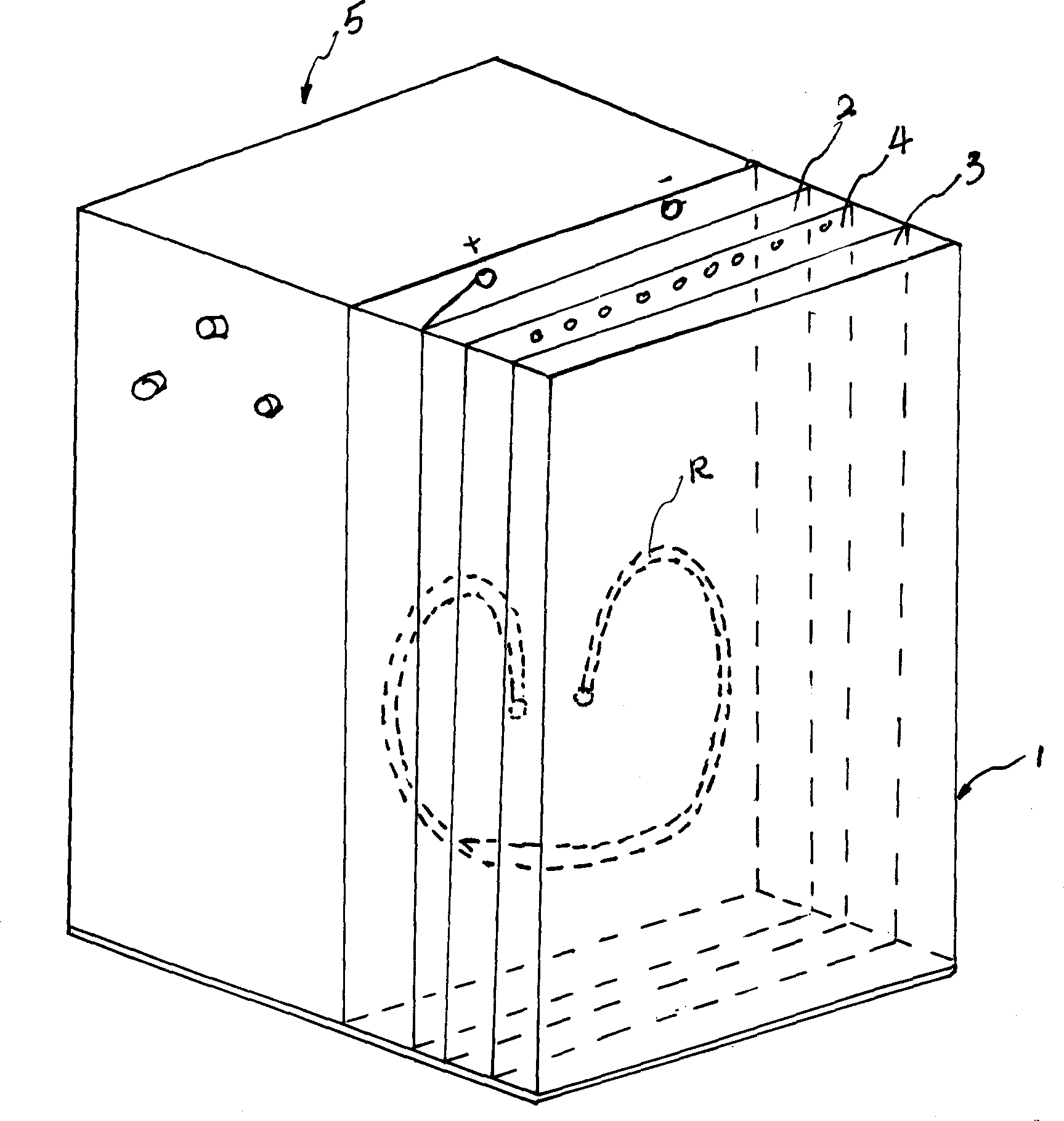

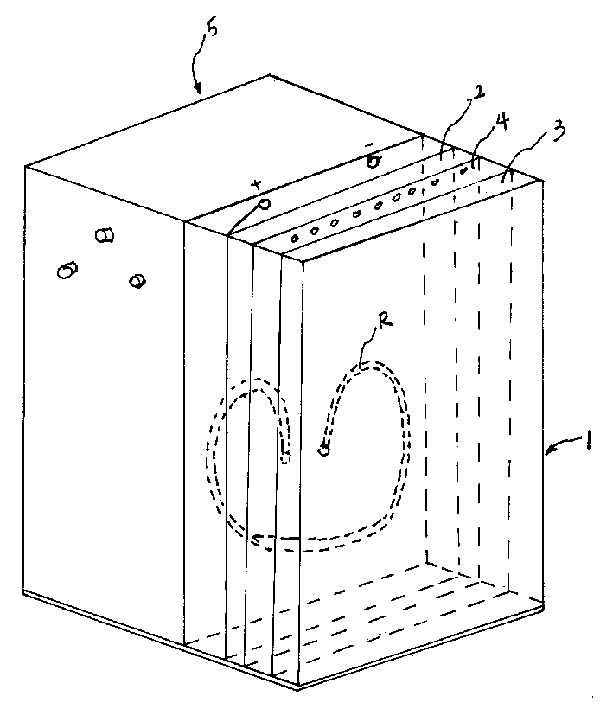

Running water paint-removing method and its water paint-removing machine

A tap water and paint stripping technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

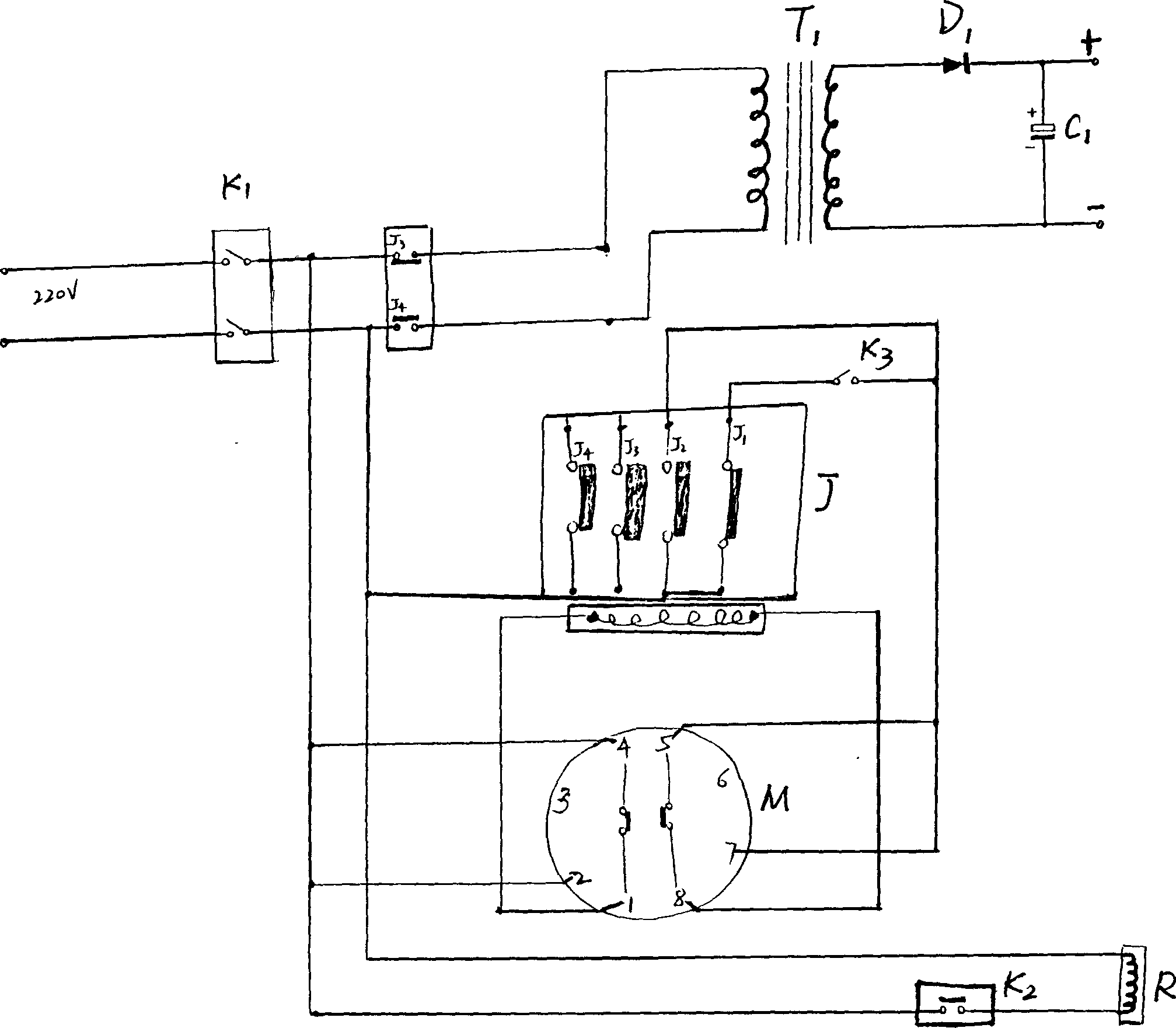

[0015] Such as figure 1 As shown, the rectification filter circuit in this embodiment is composed of a transformer T1, a rectification diode D1, and a filter capacitor C1, and the time control circuit is a time relay composed of a relay J and a timer M, wherein the two contacts of the relay J are respectively connected to The two AC input ends of the rectification filter circuit. The output voltage of the rectifying and filtering circuit in this embodiment is 50V, and the current is about 3A, which can be used for stripping paint of small metal parts such as watch case surfaces. The rectifier and filter circuit can output different output voltages according to the different paint-removing metal parts. If the object is large, the required voltage and current should be correspondingly high, so that there will be more air bubbles, and the required paint-removing time will be correspondingly longer. some. The heating element R is directly connected to 220V AC voltage, and a temp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap