High-frequency heater

A technology of high-frequency heating device and rectifying device, which is applied in microwave heating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

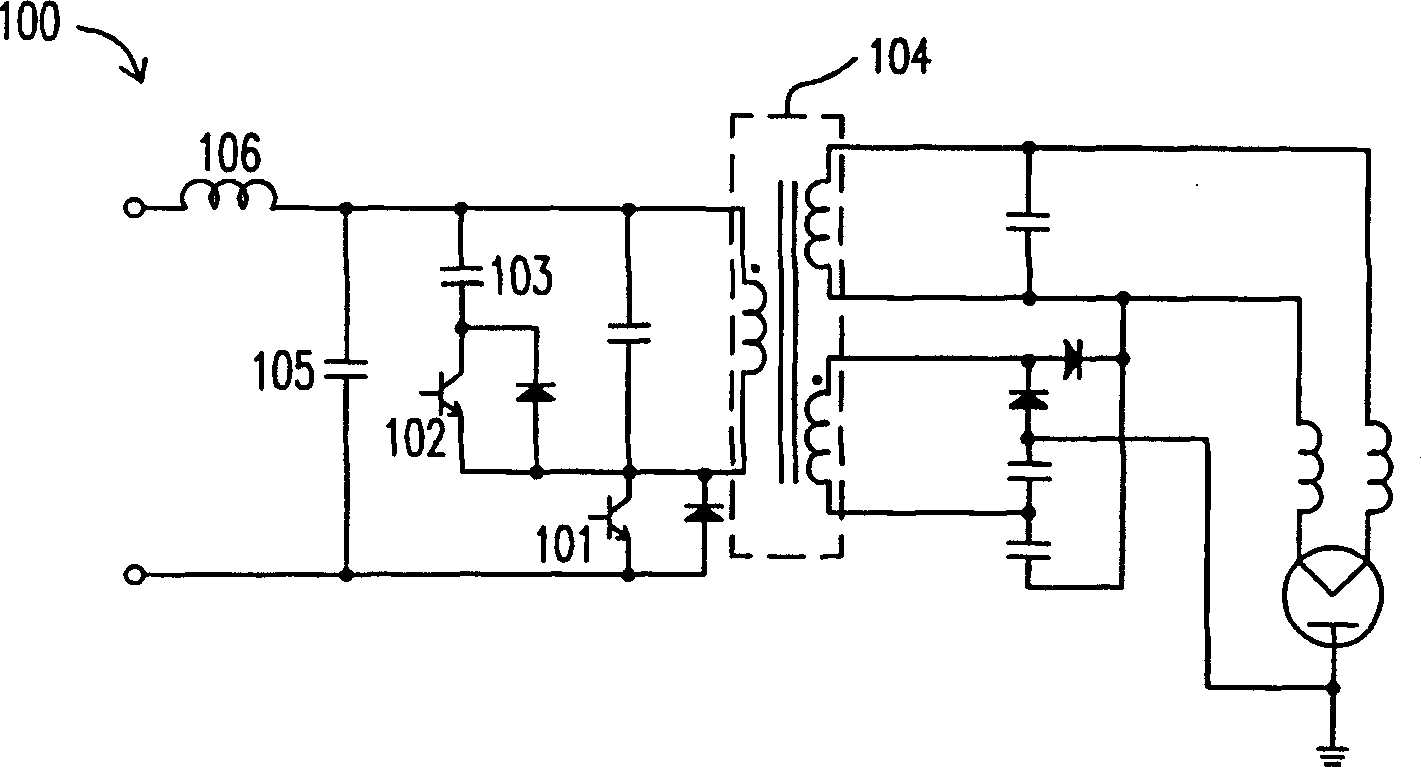

[0052] see Figure 6 , is a schematic circuit diagram of a current-mode regulating transformer DC-DC converter (DC / DC Converter) in the first preferred embodiment of the present invention, that is, a CTT (Current Tapping Transformer) DC / DC converter. Such as Figure 6 As shown, a high-frequency heating device 200 includes: a filter inductor 201, a center-tapped transformer 202, a filter capacitor 203, a first switch 204, and a series circuit including a second switch 205 and a first switch 205 connected in series. Two capacitors 206 , a first capacitor 207 , a rectifier 208 and a magnetron 209 . The filter inductor 201 is connected to a DC power supply V dc A positive terminal (+). The center tap transformer 202 includes a center tap end, a first end and a second end, and the center tap end is connected to the other end of the filter inductor 201 . The filter capacitor 203 has one end connected to the first end of the center-tapped transformer 202, and the other end connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com