Frame composed of rigid construstion element and flexible construction element

A technology of rigid components and flexible components, which is applied in the field of stable stress-bearing structural systems, can solve problems such as installation (inconvenient disassembly, consumption of steel materials, and failure to complete smoothly), and achieve the effects of light weight, steel saving, and small cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

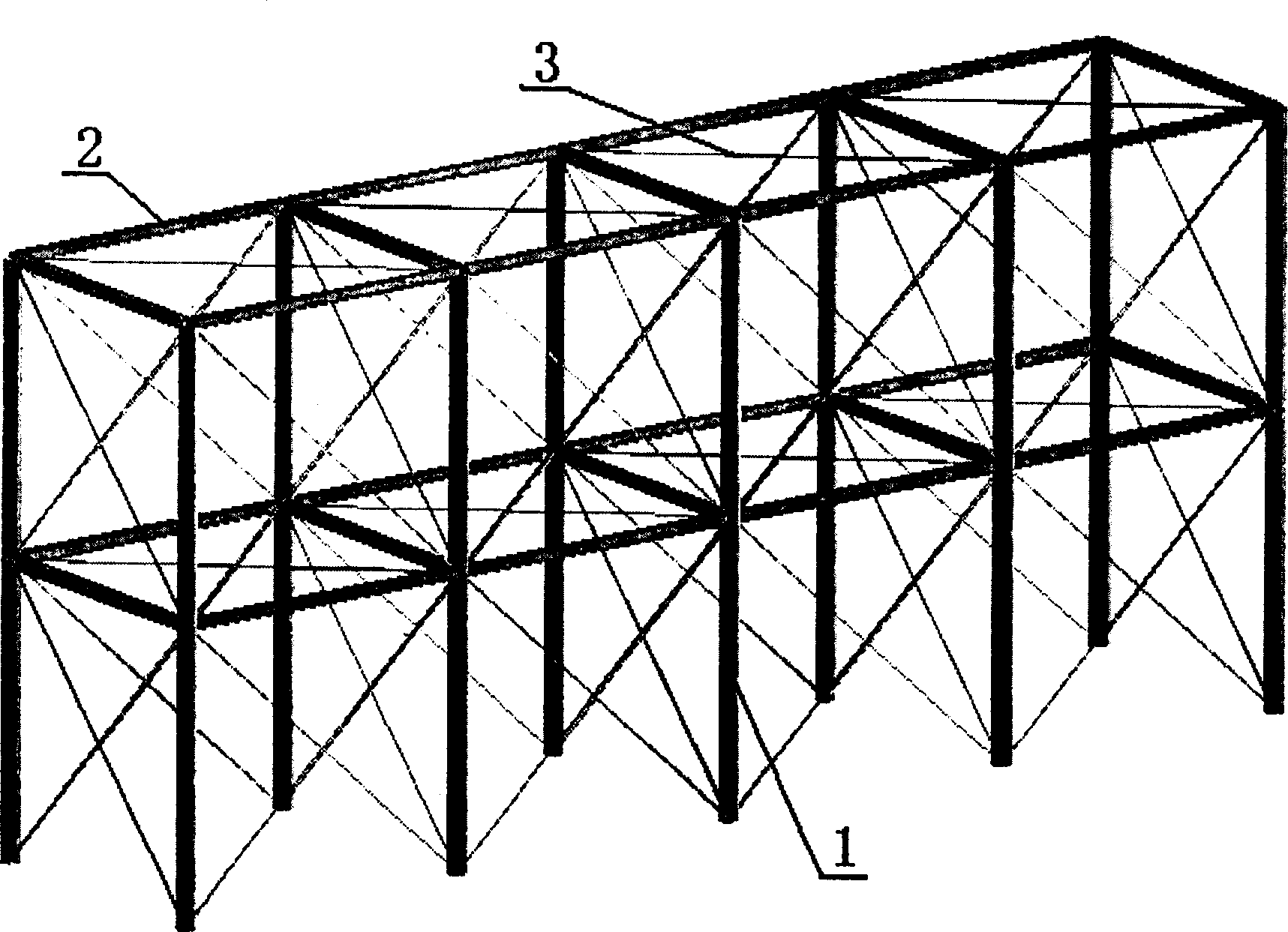

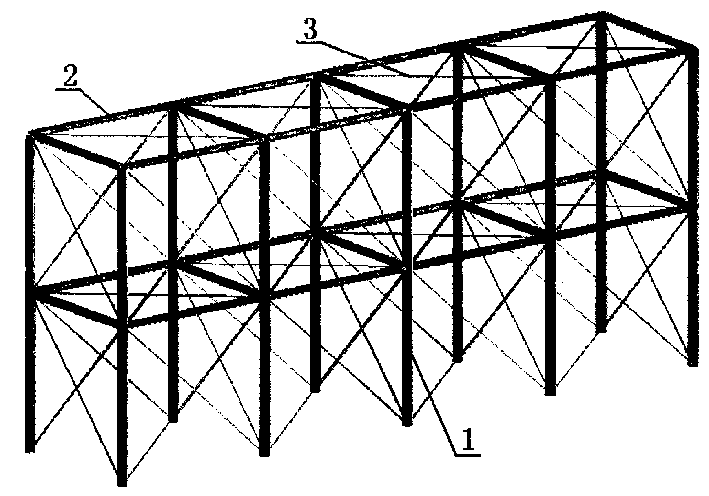

[0009] As shown in the figure, the present invention includes rigid structural members vertical columns 1 and horizontal cross braces 2, the vertical columns and horizontal horizontal braces are combined to form a three-dimensional space bent frame, in addition to flexible components pre-tensioned cable braces 3, The pre-tensioned cable bracing 3 is connected to the vertical column 1 through detachable connecting pieces in each force-bearing surface of the three-dimensional space bent frame.

[0010] The bent frame structure is mainly composed of columns and cross braces. The columns bear the vertical load, and the cross braces can reduce the calculated length of the columns and transmit part of the horizontal load. As can be seen from the figure, the combination of columns and cross braces forms an unstable three-dimensional bent frame struc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap