High-Effective bed unit disinfecting method and disinfecting machine

A bed unit and disinfection machine technology, applied in the field of medical disinfection and disinfection, to achieve the effect of solving multiple problems, thorough disinfection and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

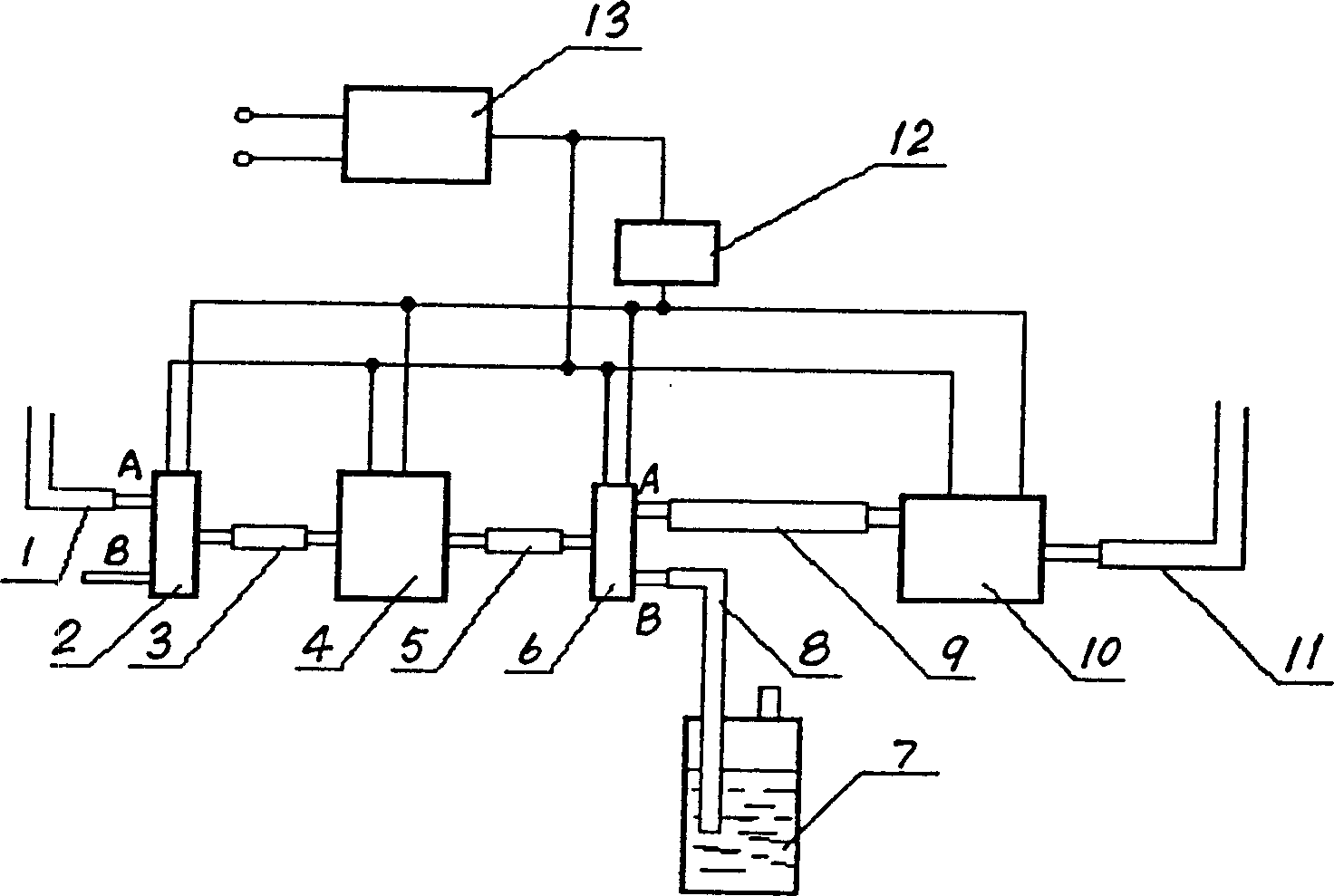

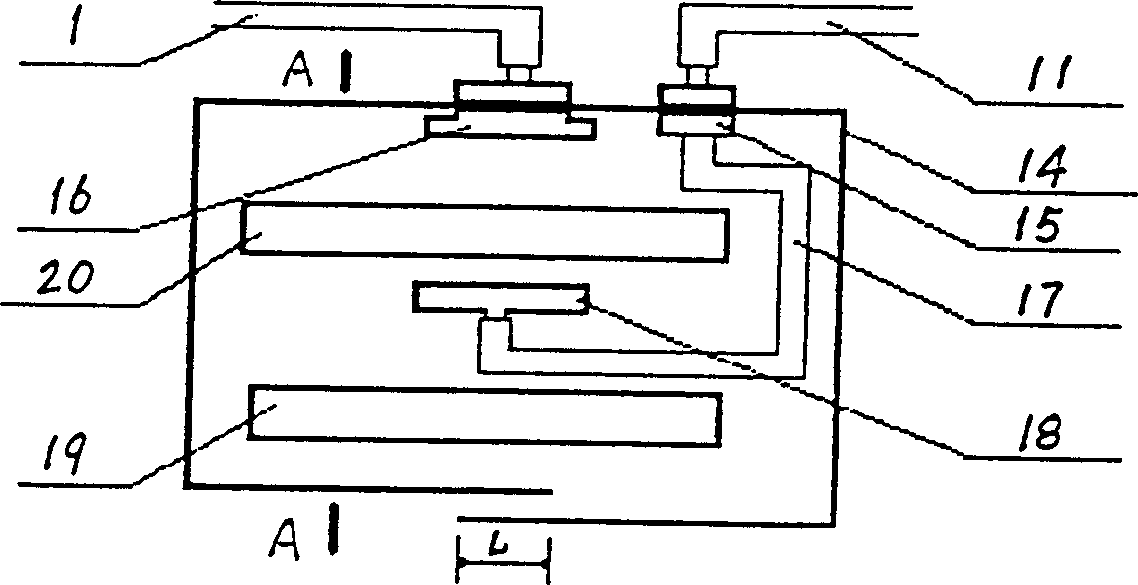

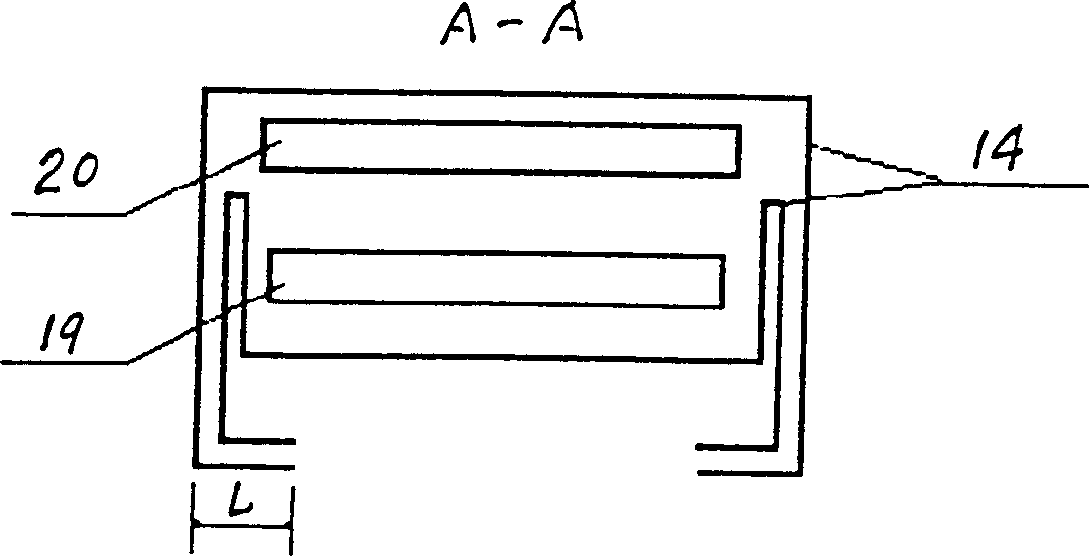

[0021] The vacuum method high-efficiency bed unit disinfection machine of the present embodiment is mainly composed of an ozone generator 10, a disinfection air bag 14 made of plastic film, a pumping air machine 4 and a chemical sterilizer 7. Wherein the output end of the ozone generator 10 is connected to the inflation joint 15 of the sterilizing air bag 14 by an inflatable plastic pipe. The air extraction connector 16 of the disinfection air bag 14 is connected to the A port of the inlet solenoid valve 2 through the air extraction plastic pipe, and then connected to the air extraction port of the air extraction air machine 4 by connecting the plastic pipe 3. The air pressure port of the pumping air machine 4 is connected to the outlet electromagnetic valve 6 through the connecting plastic pipe 5, and then connected to the air inlet of the ozone generator 10 through the connecting plastic pipe 9. The B port of the inlet electromagnetic valve 2 is connected to the atmosphere, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com