Rotary dobby machine for weaving machine and weaving machine with said rotary dobby machine

A technology of dobby looms and looms, applied in dobby machines, textiles, papermaking, textiles, etc., can solve problems such as shortening service life, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

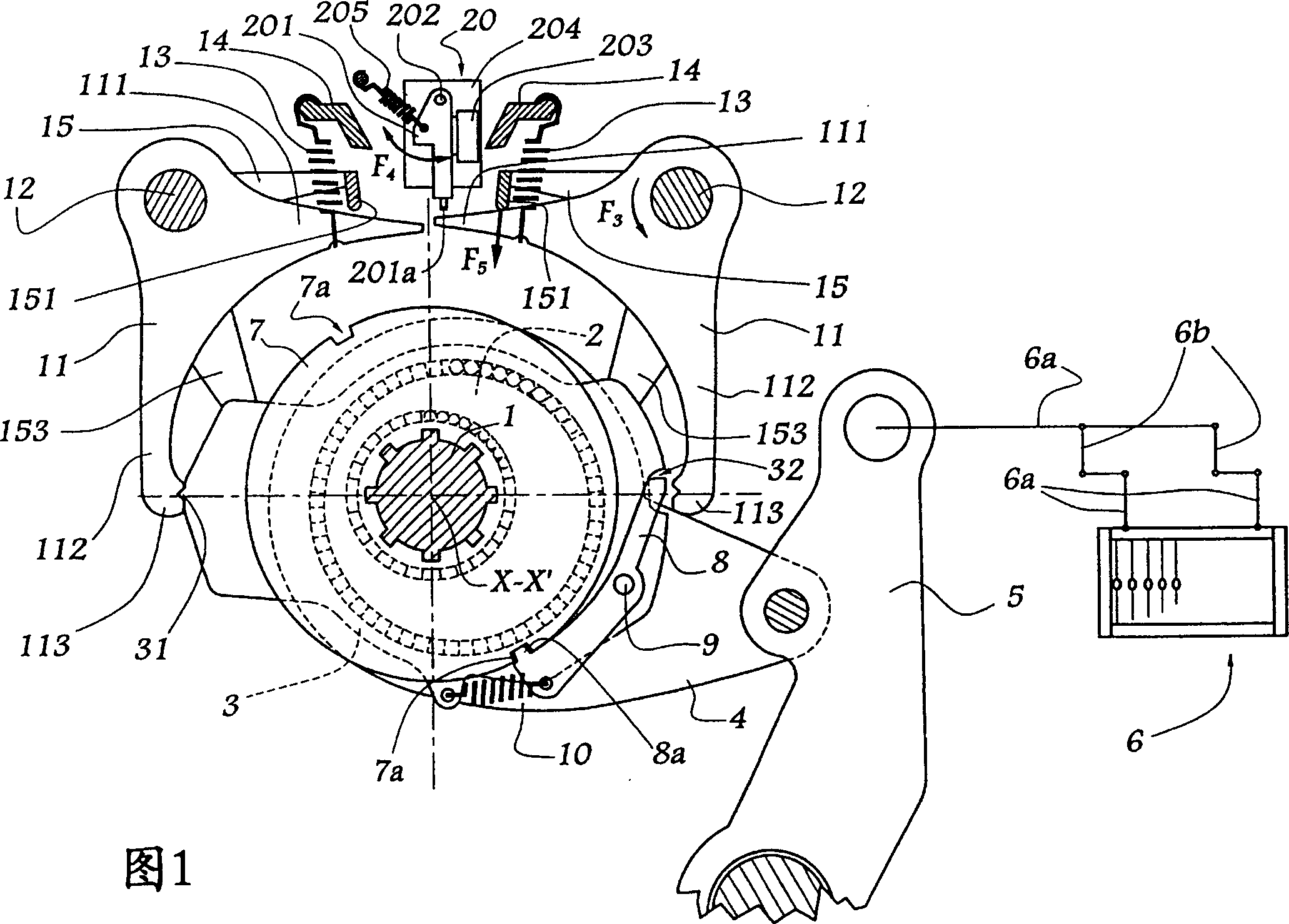

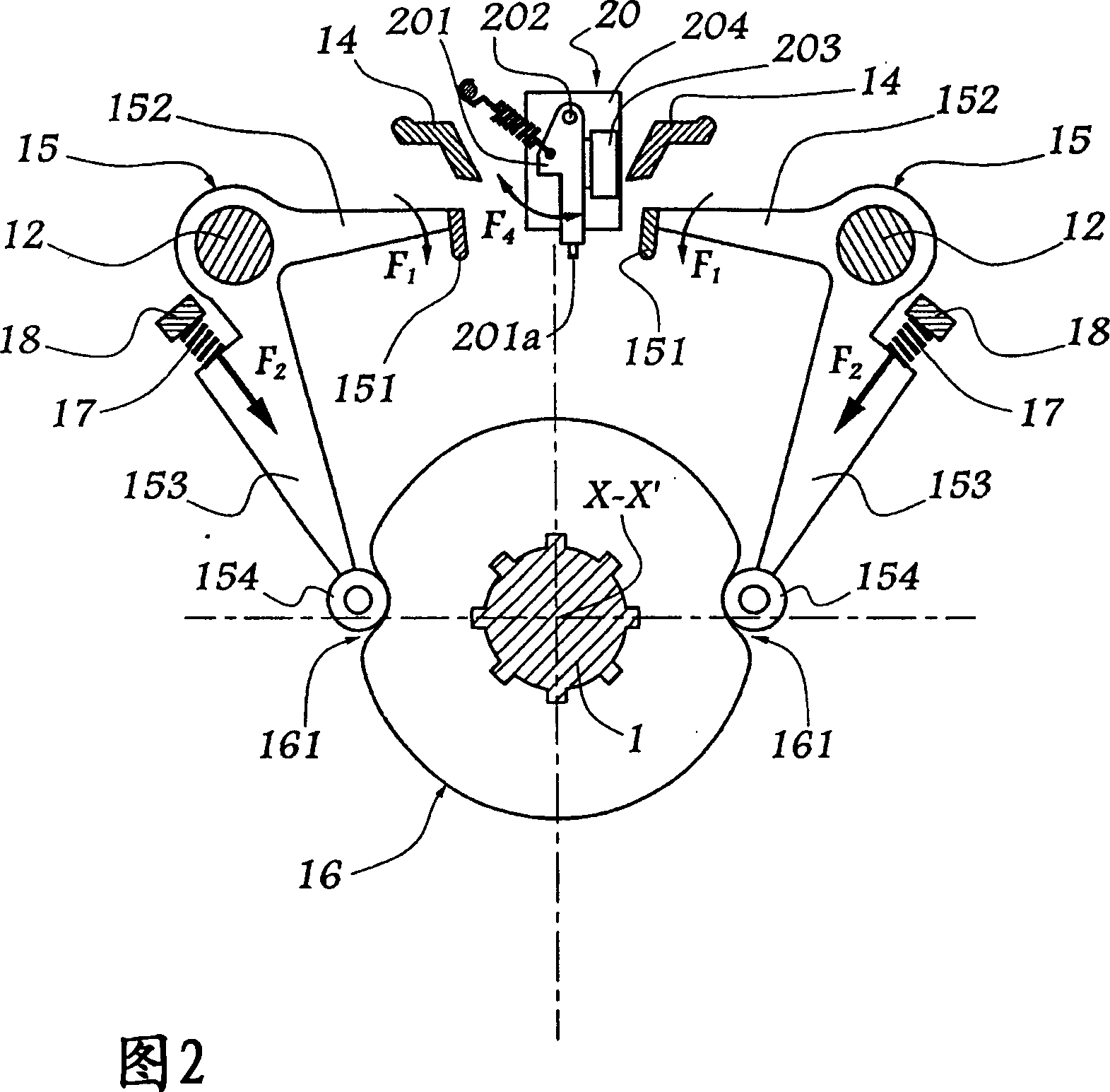

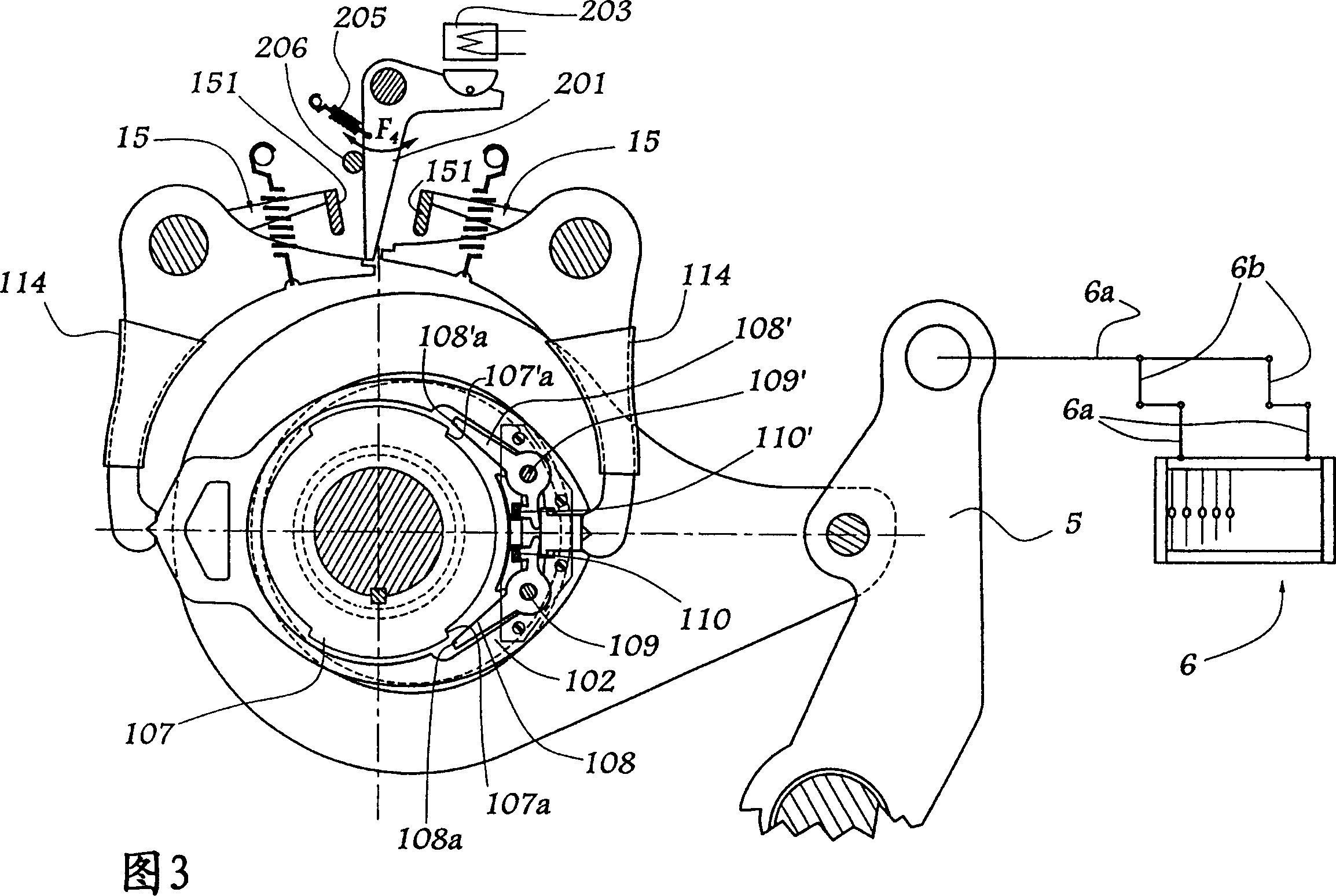

[0019] Referring now to the drawings, the dobby shown in Figures 1 and 2 comprises a main shaft 1 energized by intermittent rotary motion which stops every half revolution. The shaft 1 houses a series of roller bearings, the number of which is the same as the number of healds or needle bars of the loom. A laterally extending eccentric 2 is mounted loosely on each roller bearing with a disc (plate) 3 . On each eccentric 2 the opening of the connecting rod 4 is installed empty, the free end of the connecting rod 4 is connected with the pivot arm 5, which ensures the The vertical movement of the heddle 6 of the needle bar, the heddle 6 is shown schematically in the figure.

[0020] Between two adjacent eccentrics 2, the splined shaft 1 supports a drive disc 7, which is firmly connected to the shaft 1 and has two diameters cut out diametrically opposite each other on its periphery. to the notch 7a. These notches 7 a are intended to selectively receive the end fingers 8 a of a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com