Method for cleaning track and ballast

A technology for track and ballast, which is applied in the field of screening device to screen the track ballast and dirt, and can solve problems such as water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

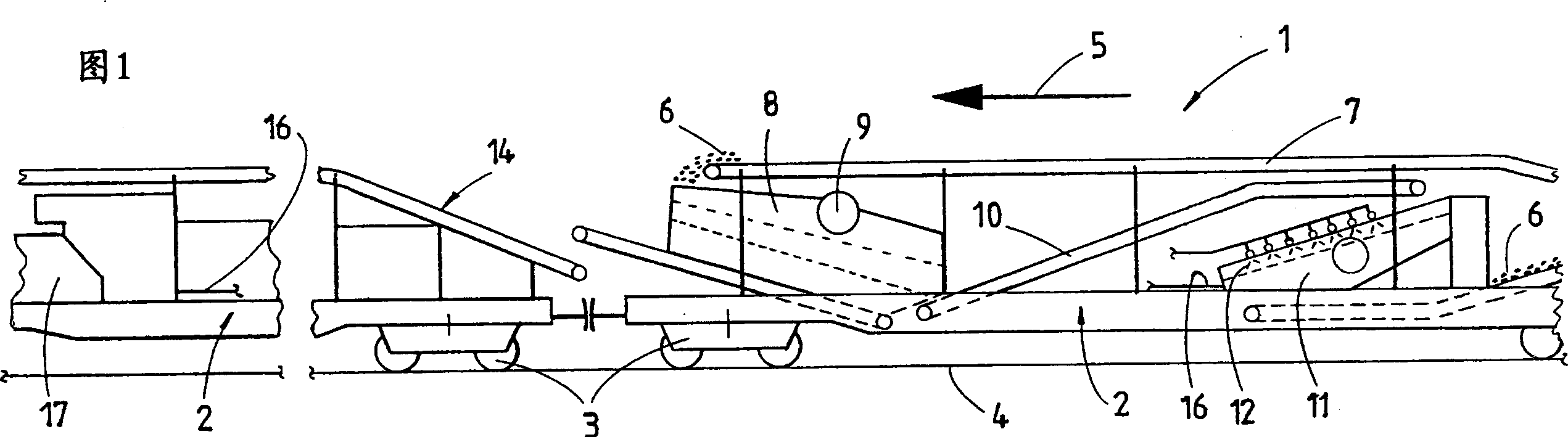

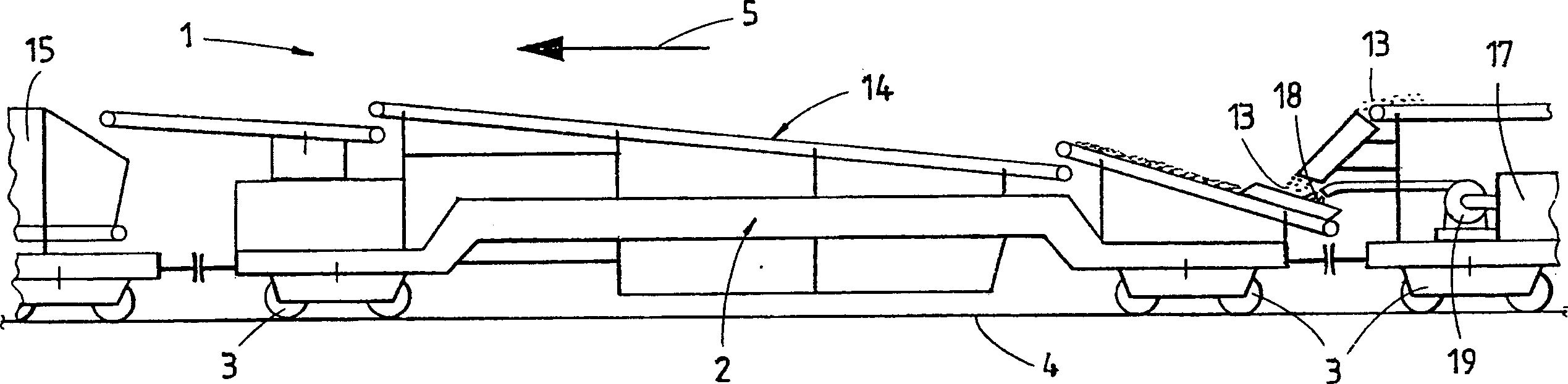

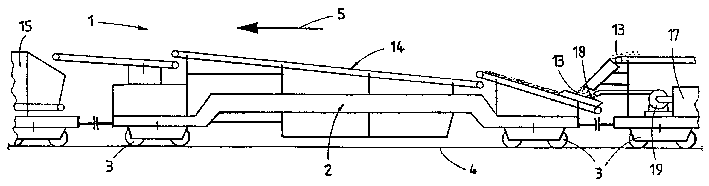

[0008] Partially shown machinery 1 among Fig. 1 and 2 is made up of several linked vehicles 2, utilizes track mechanism 3 to be able to walk on track 4 along working direction 5. As is known, the ballast 6 of the track 4 can be excavated by means of an excavating chain not shown in the figure, and then conveyed via a conveyor belt 7 to a screening device 8 equipped with a vibration drive 9 .

[0009] The ballast 6 that this mechanization method preliminarily sieves clears continues to be sent into cleaning device 11 by conveyer belt 10, and is cleaned under the situation of spraying into water 12. Thereafter the ballast 6 through twice cleaning will be thrown below the track 4 again.

[0010] The dirt 13 separated from the ballast 6 by the screening device 8 is sent to the storage car 15 through the conveyor belt unit 14 . The water 12 sprayed in the cleaning device 11 is pumped via a line 16 into a cleaning device 17 and is cleaned if sediment is formed. Utilize pump 19 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com