Moulding apparatus with external mold block cooling

A technology of model blocks and equipment, applied to corrugated products, household appliances, and other household appliances, etc., can solve the problems that the cooling air cannot keep in contact with the model blocks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

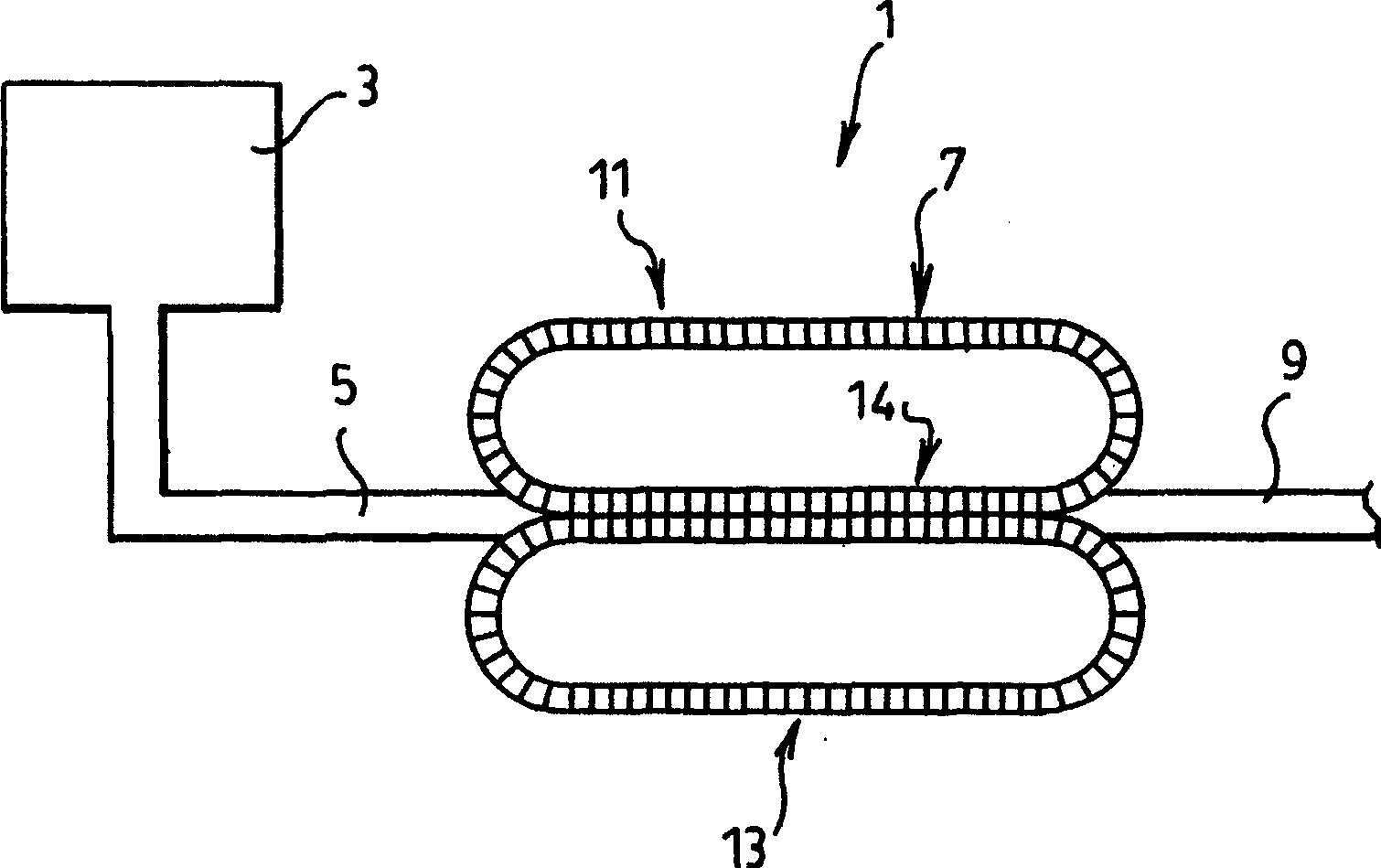

[0016] figure 1 The pipe molding apparatus 1 shown comprises an extruder 3 which sends molten plastic through a die 5 to a plastic corrugator 7 . The plastic corrugator 7 includes an upper annular formation 11 and a lower annular formation 13 of model block segments which are brought together to form a mold tunnel which accepts molten plastic to form a plastic tube 9. The plastic pipe is discharged from the downstream end of the mold channel.

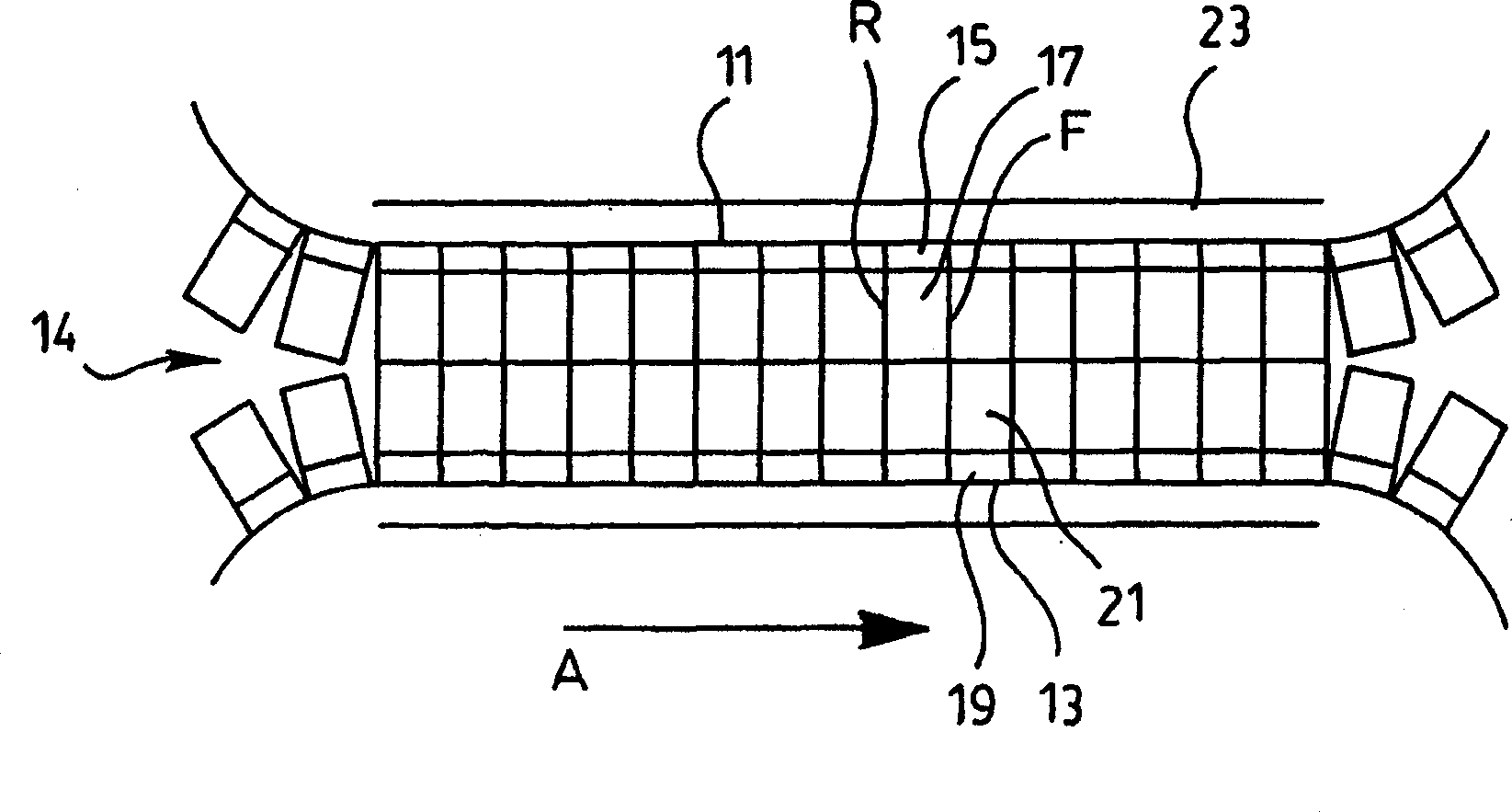

[0017] figure 2 Model block segments 17 are shown loaded by model block segment conveyor chain 15 into the upper queue 11 of the corrugator and model block segments 21 are loaded by conveyor chain 19 into the lower queue 13 of the corrugator. These upper and lower rows of model block segments all move in the direction of arrow A through the model tunnel 14 . Each model block segment such as figure 2 Reference numeral 17 is shown having a front F and a rear R facing the direction of movement of the model block through the model tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com