Switchboard

A switchboard and equipment installation technology, applied in substation/power distribution device casing, electrical components, substation/switch layout details, etc., can solve problems such as equipment skew, deterioration of completed state, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

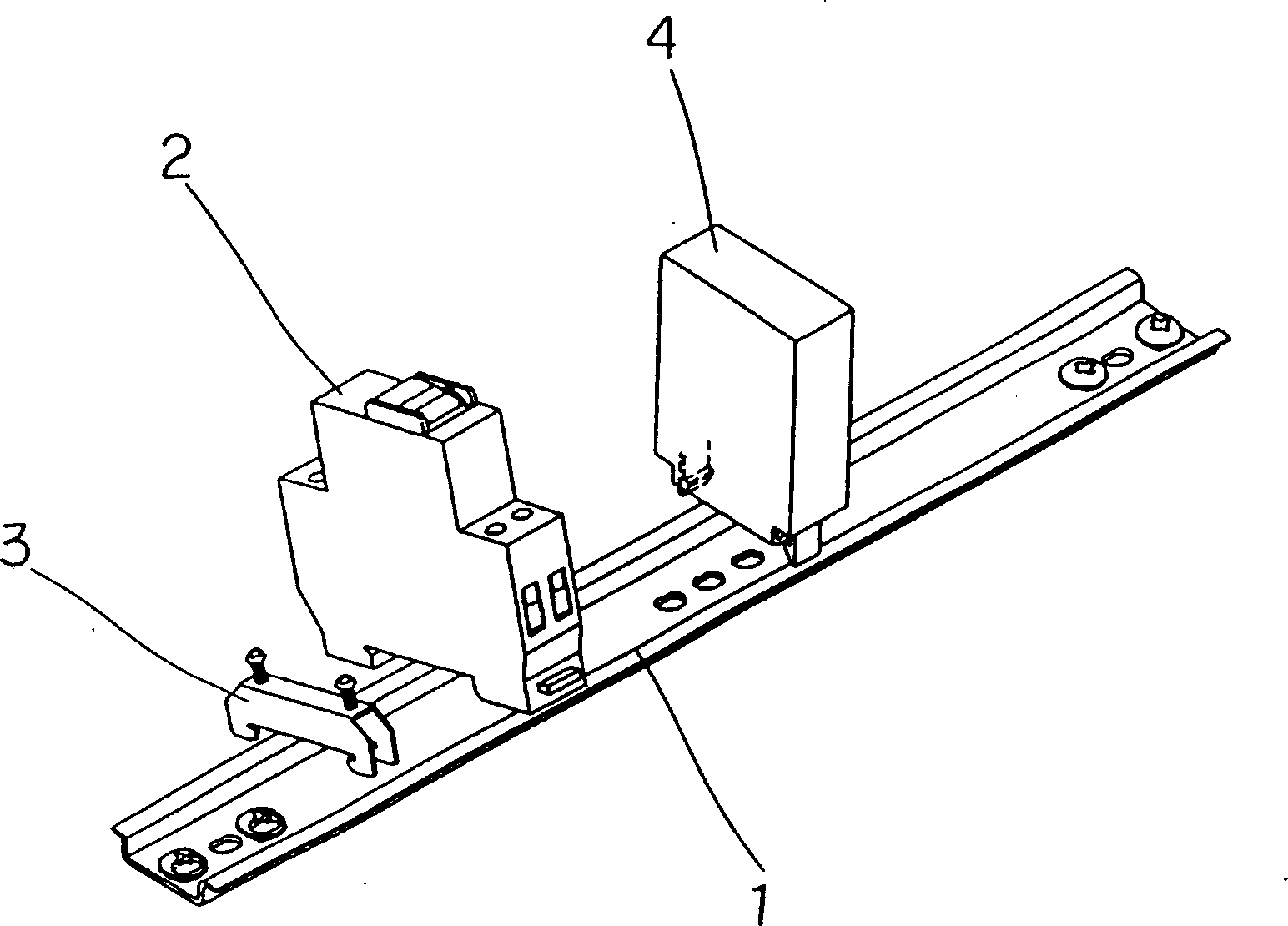

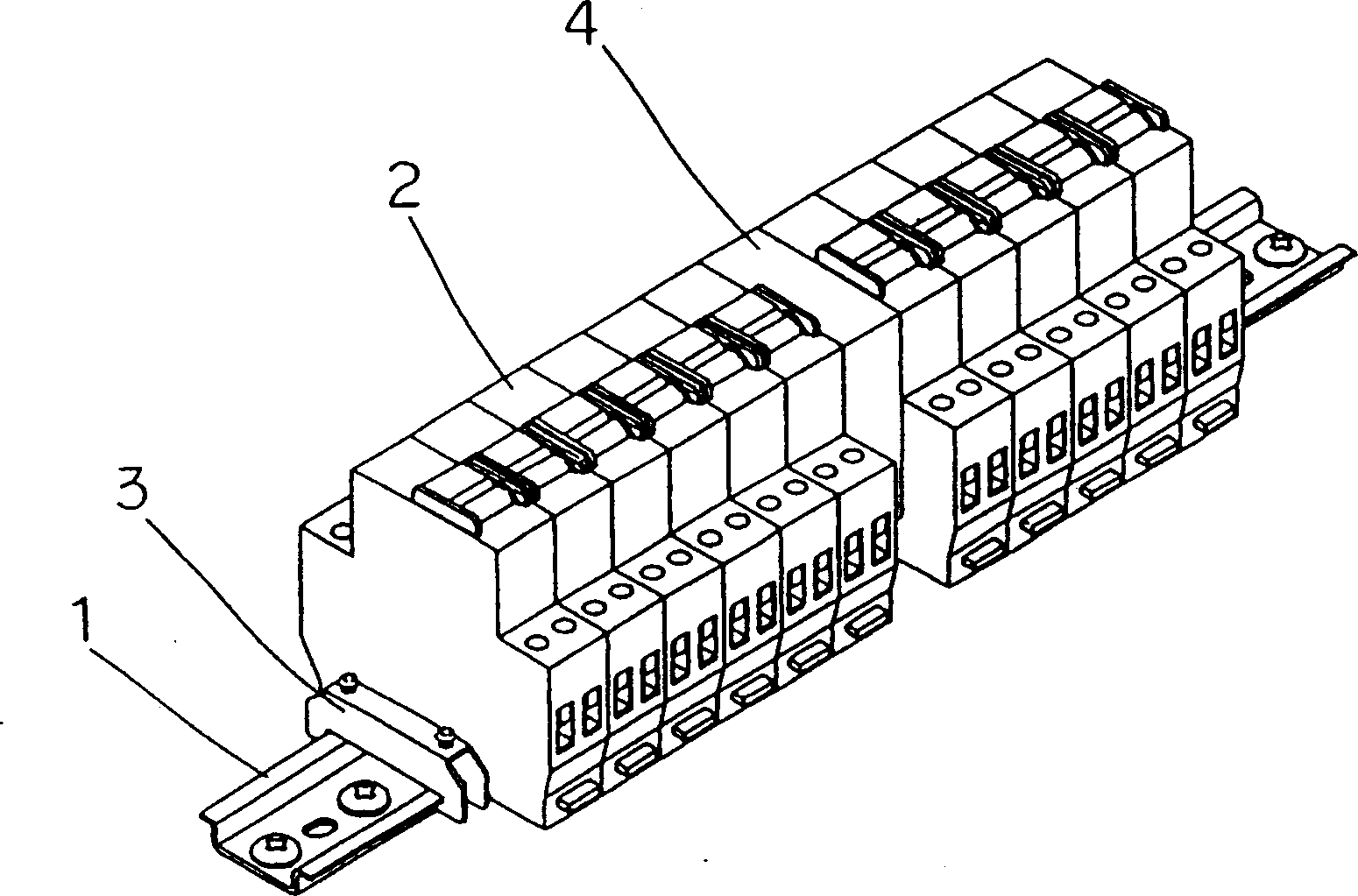

[0021] refer to Figure 1 to Figure 4 The accompanying drawings illustrate an embodiment of the switchboard of the present invention.

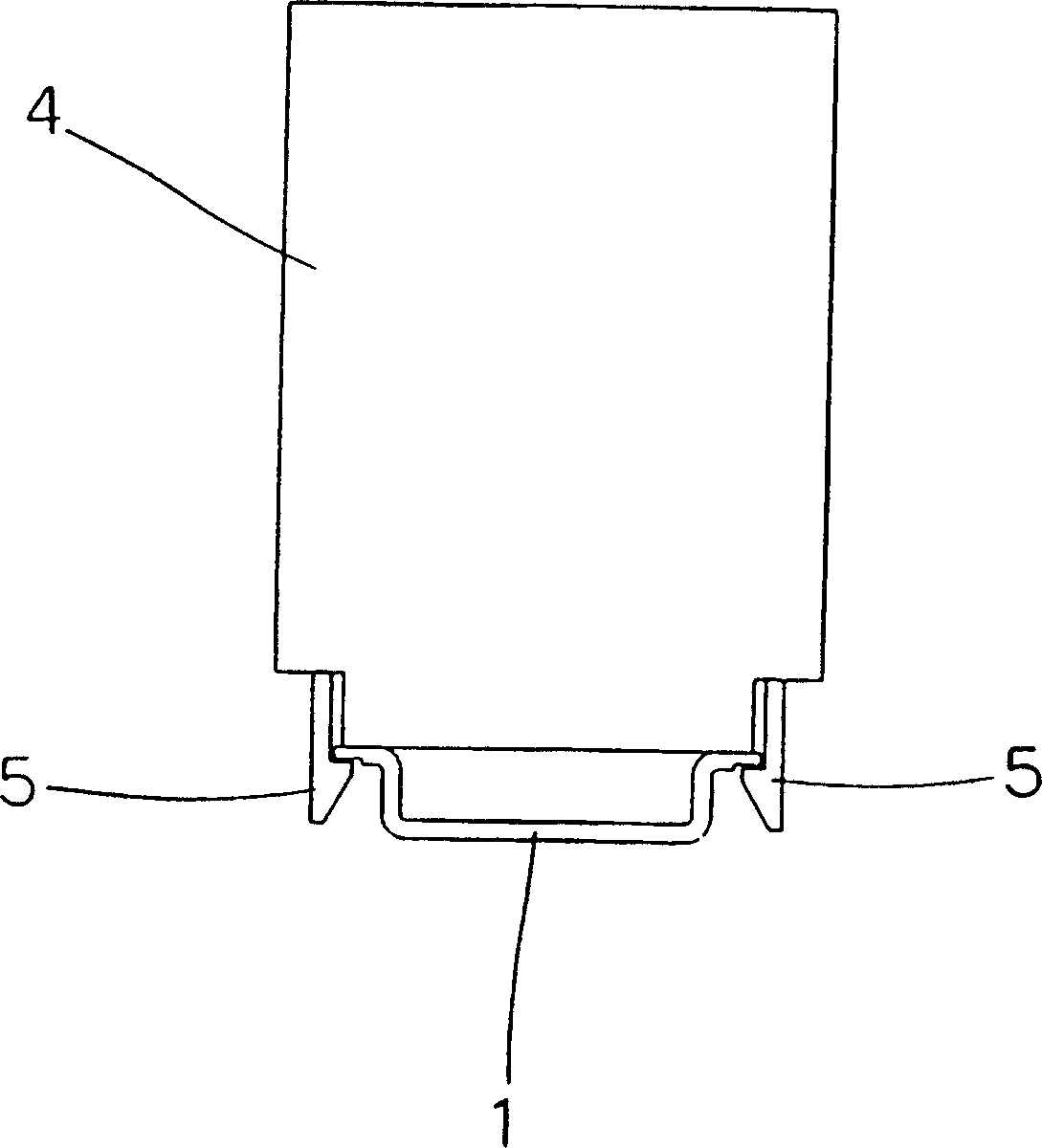

[0022] The configuration is such that the panel is installed on the switchboard, the equipment installation rail 1 is laid on the panel, and equipment such as the circuit breaker 2 is arranged on the equipment installation rail 1 . The equipment installation rail 1 is cut into the required length in advance, bolts are fastened on the panel, and the fixtures 3 for equipment positioning are installed on the left and right of the equipment installation rail 1 . Arrange the circuit breakers 2 between the fixing pieces 3 .

[0023] When there is a gap between the circuit breaker 2 and the circuit breaker 2, a spacer 4 formed in a shape similar to the circuit breaker 2 and having the same width as the circuit breaker 2 is installed on the equipment installation rail 1 to fill the gap. At the same time, the circuit breaker 2 is supported.

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com