Medium testing fixtutre for PDP-plate

A hose and flexible technology, applied in the field of flexible hoses, can solve problems such as reducing the bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

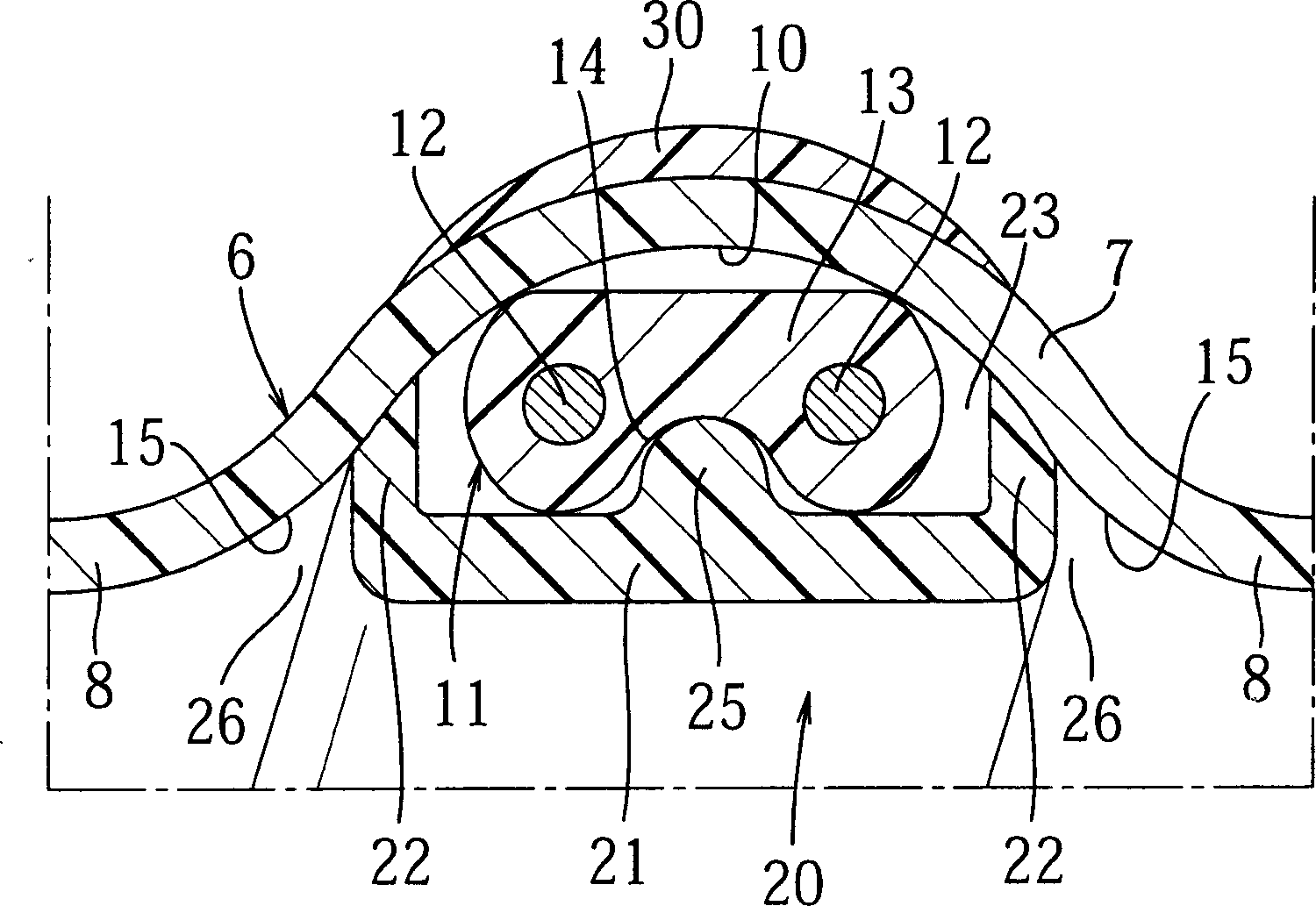

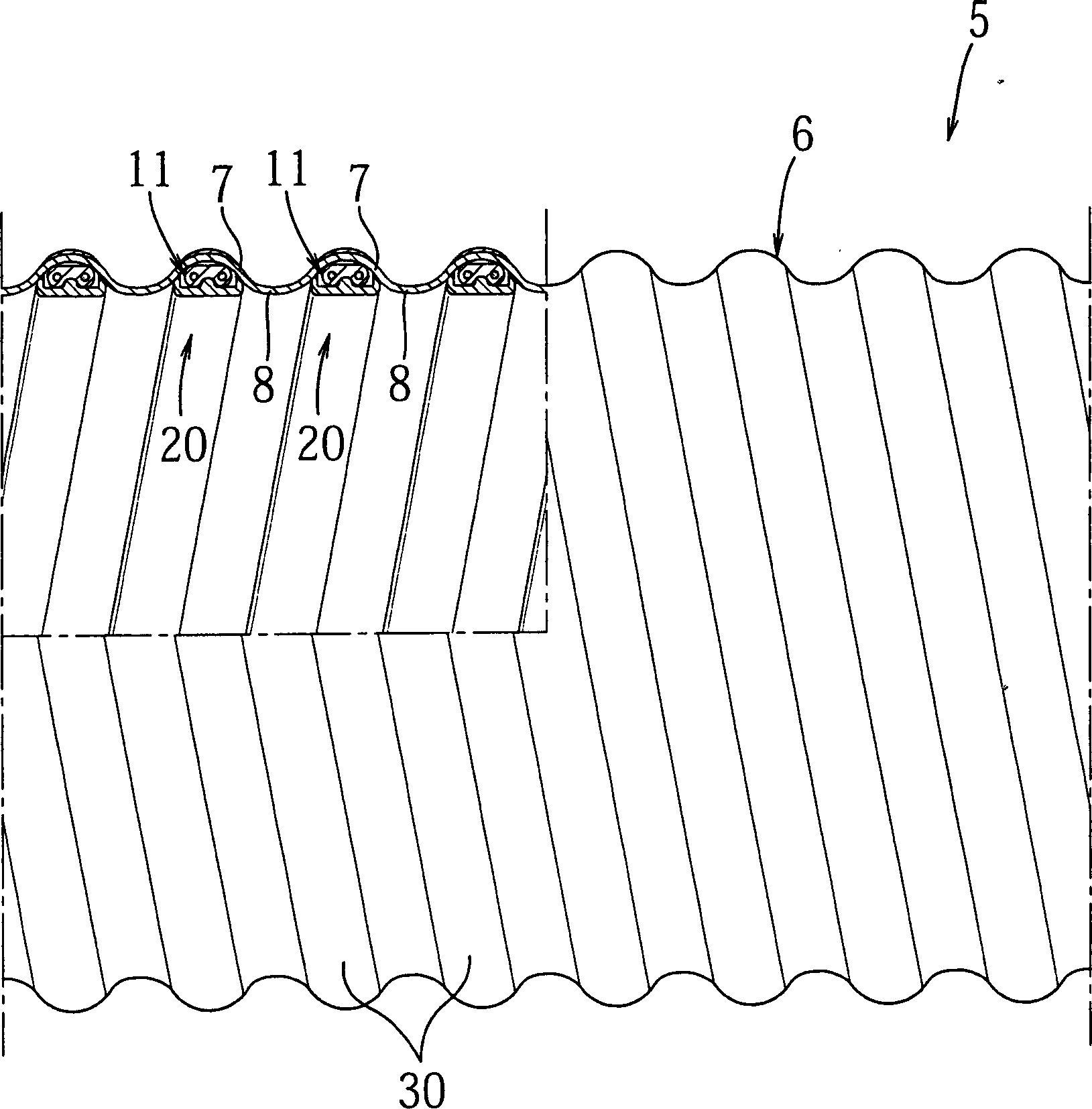

[0024] Hereinafter, an embodiment of the present invention will be described in detail based on the drawings. The flexible hose of an embodiment of the present invention, such as figure 2 As shown, in the electric vacuum cleaner 1, it is used as the vacuum cleaner hose 5 which connects the operation cylinder 3 which has the suction nozzle 2, and the vacuum cleaner main body 4. Especially useful as a wet cleaner hose for suctioning liquids such as water.

[0025] The pipe wall 6 of the vacuum cleaner hose 5 is spirally wound with a resin belt made of, for example, a soft synthetic resin material such as dechlorinated vinyl, a soft synthetic resin material such as vinyl chloride, or a material mixed with rubber or the like. , and overlap and weld or overlap and weld the side edges of the front resin tape and the rear resin tape.

[0026] The pipe wall 6 is transparent or translucent so that the flow state of the fluid passing through the inside can be visually confirmed. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com