Articles transfer device

A technology for handling devices and objects, which is applied in the direction of object destacking, transportation and packaging, object stacking, etc., which can solve the problems of increasing assembly workpieces and increasing product production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

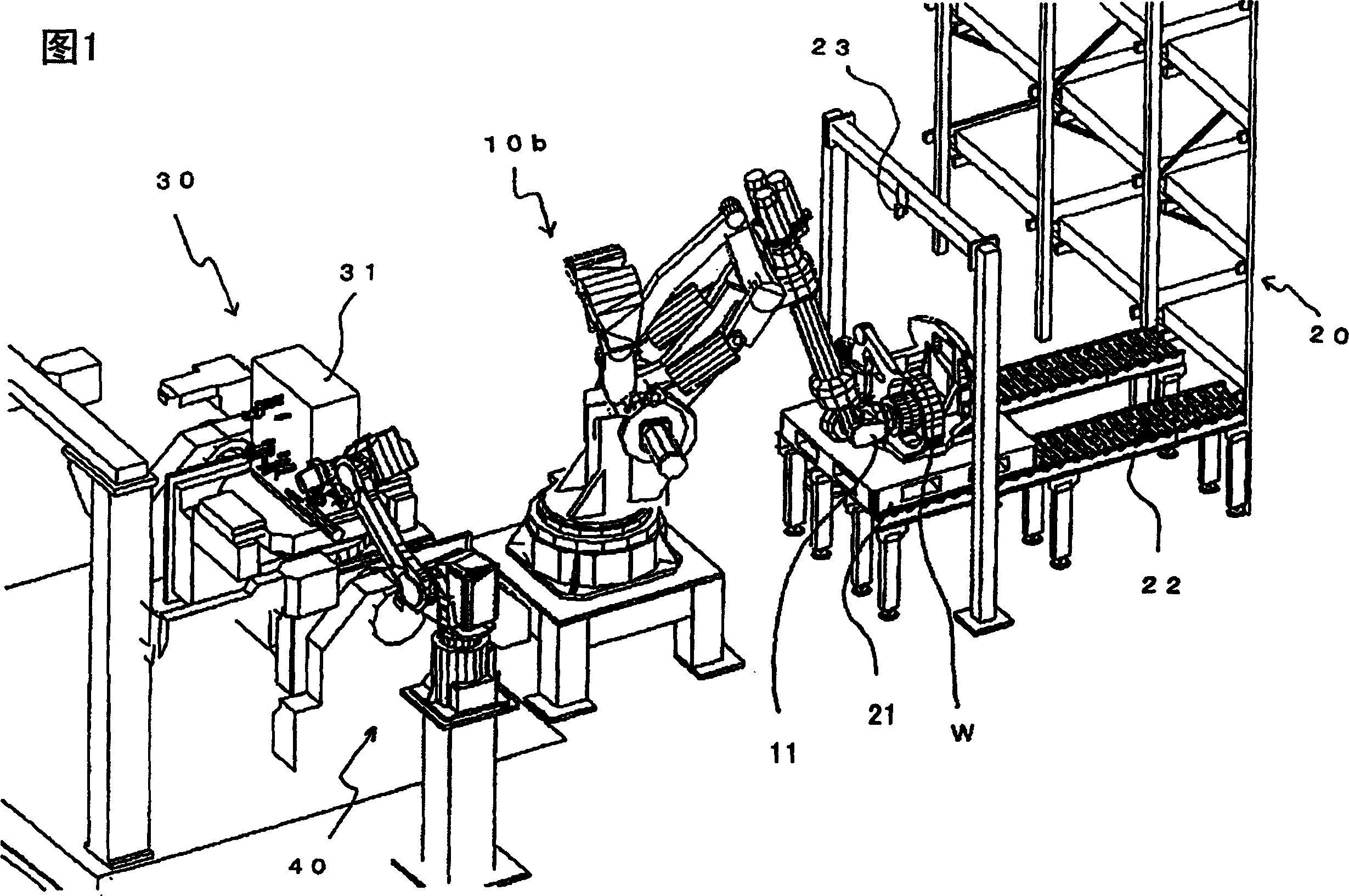

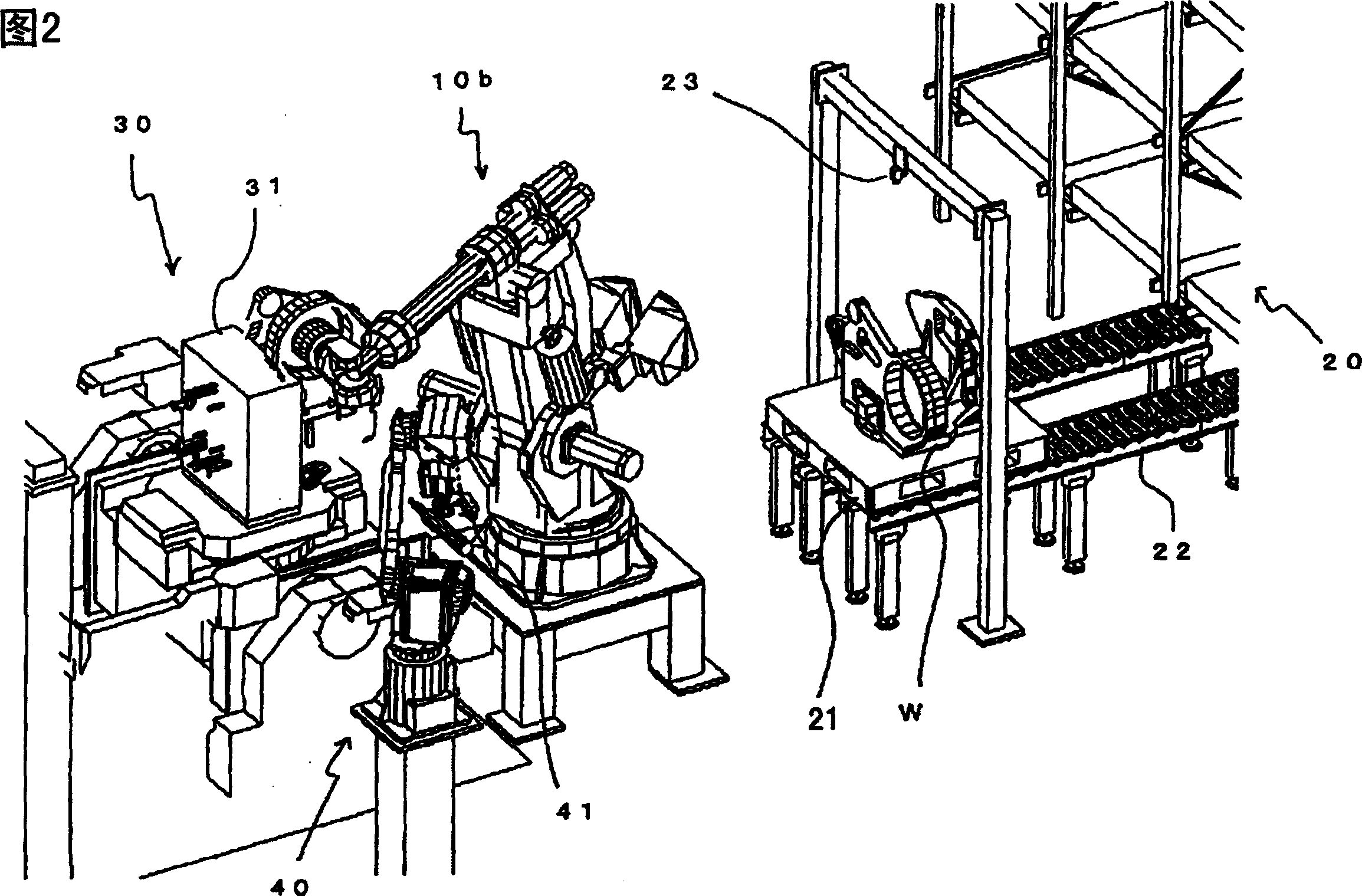

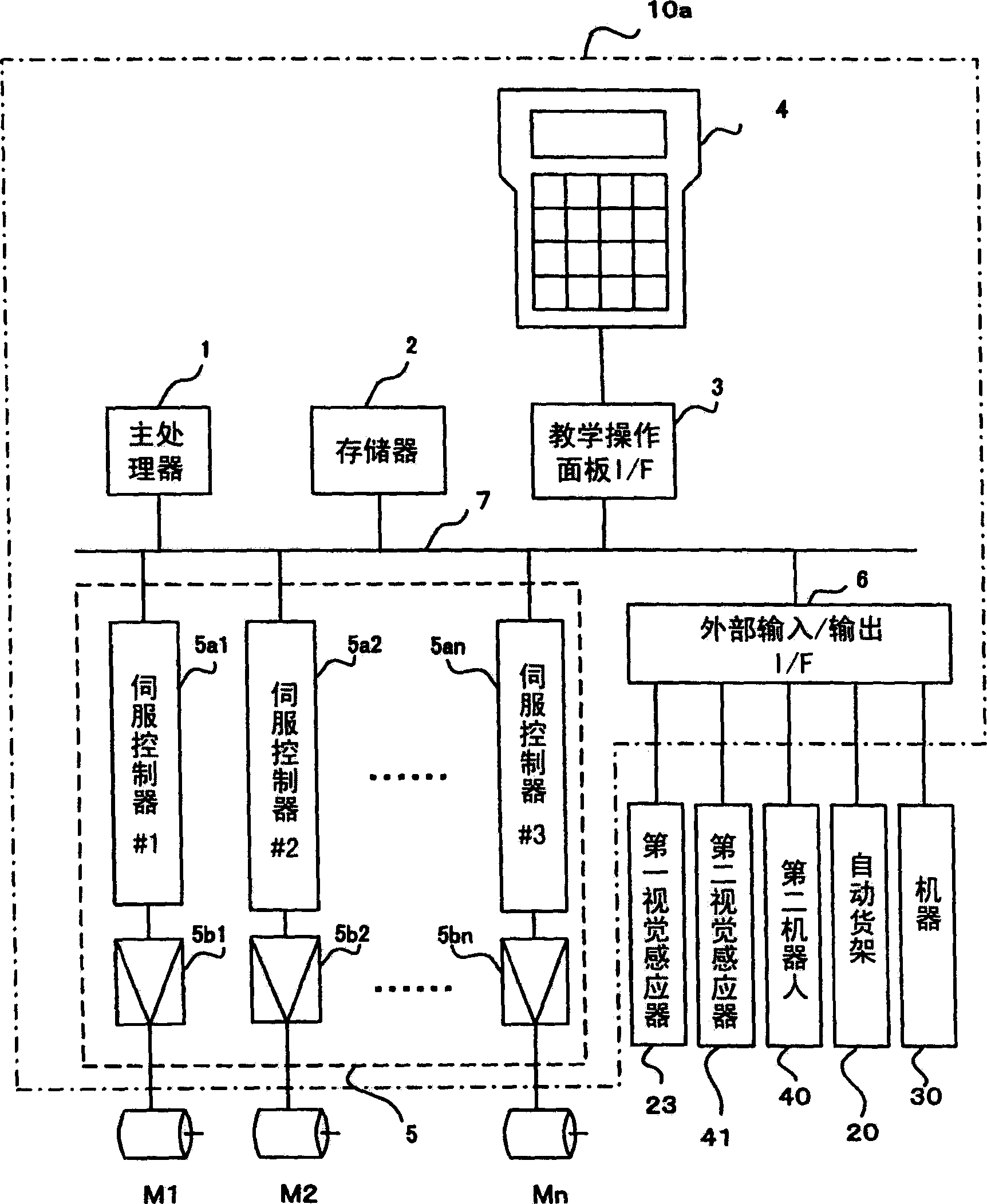

[0016] First, with reference to Figures 1 and 2, the overall structure of an object handling device according to an embodiment of the present invention will be described.

[0017] As shown in FIG. 1 , the articles W placed on the pallet 21 and stored in the automatic rack 20 are supplied to the article supply location through the conveyor 22 along with the pallet 21 . The first robot 10b is disposed at a position where its operating range can cover a workpiece supply site and an installation site of a machine 30 such as a machine tool. The first robot 10 b clamps the object W through a robot hand 11 attached to the wrist, removes the object W from the pallet 21 , and transfers the clamped object W to the object fixing and clamping device 31 of the machine 30 .

[0018] The first visual sensor 23, as a first detecting means for detecting the position / direction of the supplied article W, is provided near the article supply location. The first vision sensor 23 may be a two-dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com