Discharge-amount limiting tool for pumping liquid container

A liquid container and discharge volume technology, applied in liquid distribution, household utensils, brackets or dispensers, etc., can solve problems such as waste, environmental pollution, liquid waste, etc., and achieve the effect of easy removal and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

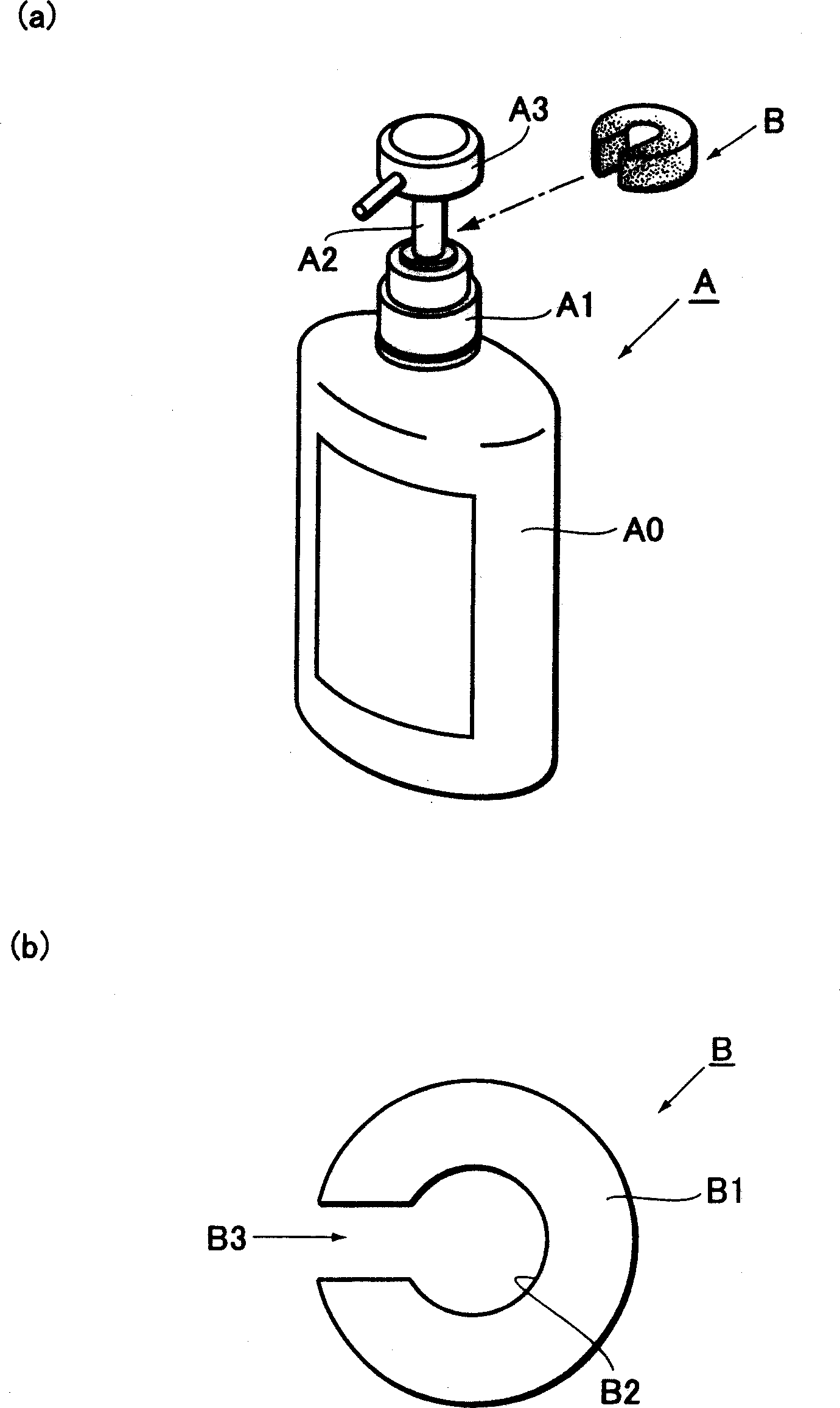

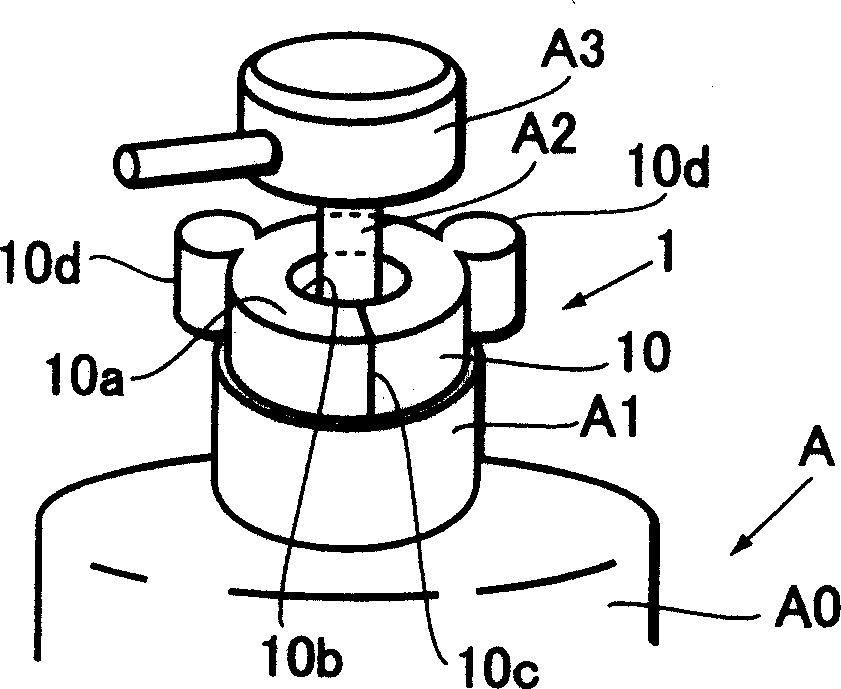

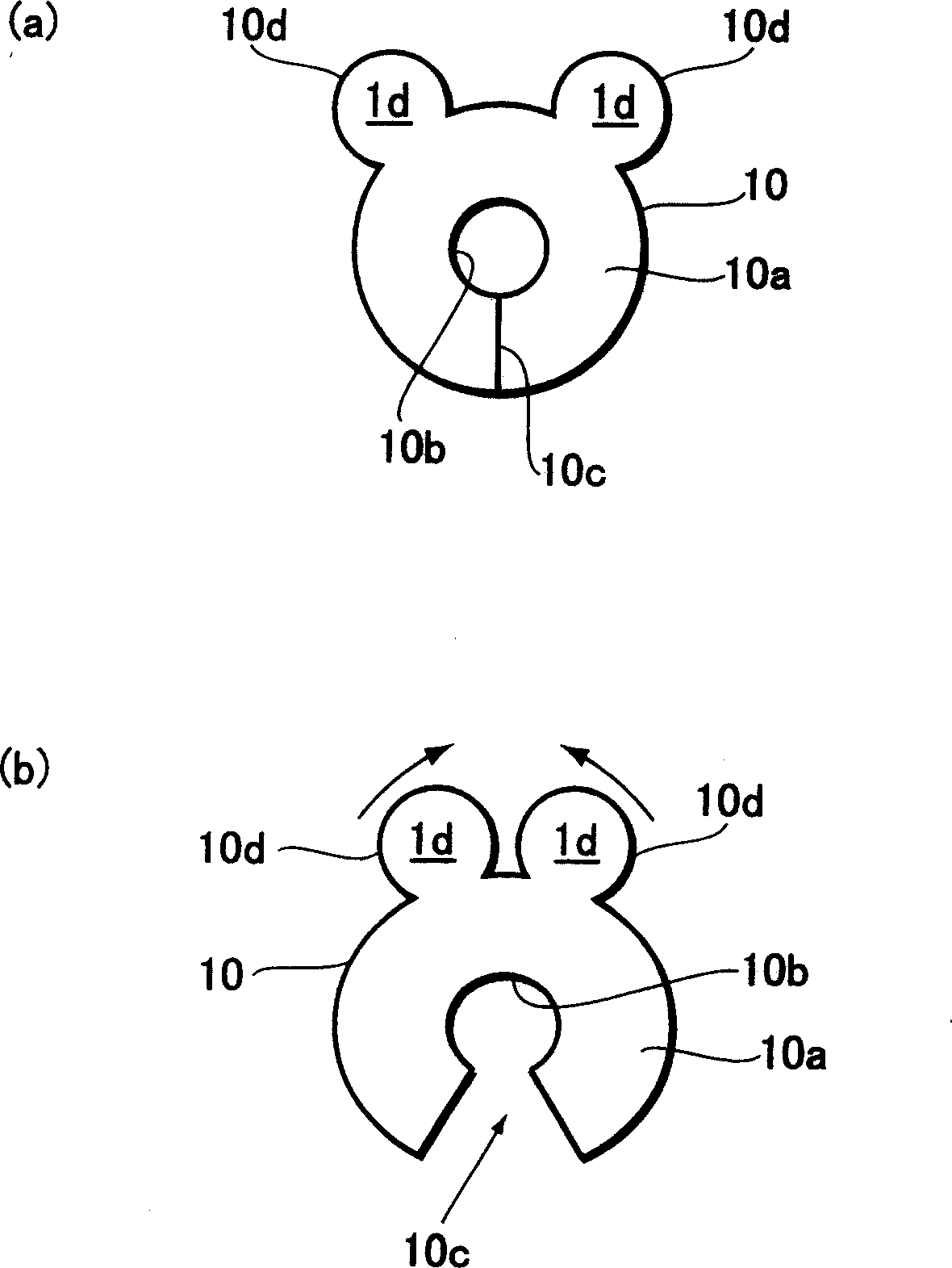

[0062] Figure 11 (a) is an explanatory diagram of the dimensional relationship between the pump-type liquid container and the discharge amount restrictor attached thereto in the embodiment of the present invention.

[0063] With regard to the width L1 of the main body member 10 in the discharge amount restrictor 1, since the lower surface of the nozzle A3 must abut against the receiving portion 10a to stop the push-in of the suction pipe A2, it must be made wider than the width of the nozzle A3. W is bigger. In addition, the diameter L2 of the mounting hole 10b in the main body member 10 is generally larger than the outer diameter of the threaded portion A4 formed on the suction pipe A2, and it is better that the threaded portion A4 does not get stuck in the mounting hole 10b.

[0064] The nozzle A3 is usually made of plastic, such as Figure 11 As shown in (b), it is formed by connecting the suction pipe A2 and the nozzle A3 by several ribs A5. Figure 11 (b) is a perspec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com