Timepiece

A technology for timepieces and watchcases, which is applied to clocks, instruments, casings, etc. It can solve the problems of easy rusting of soft magnetic materials, large total thickness of antimagnetic watches, and difficult to obtain polished surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

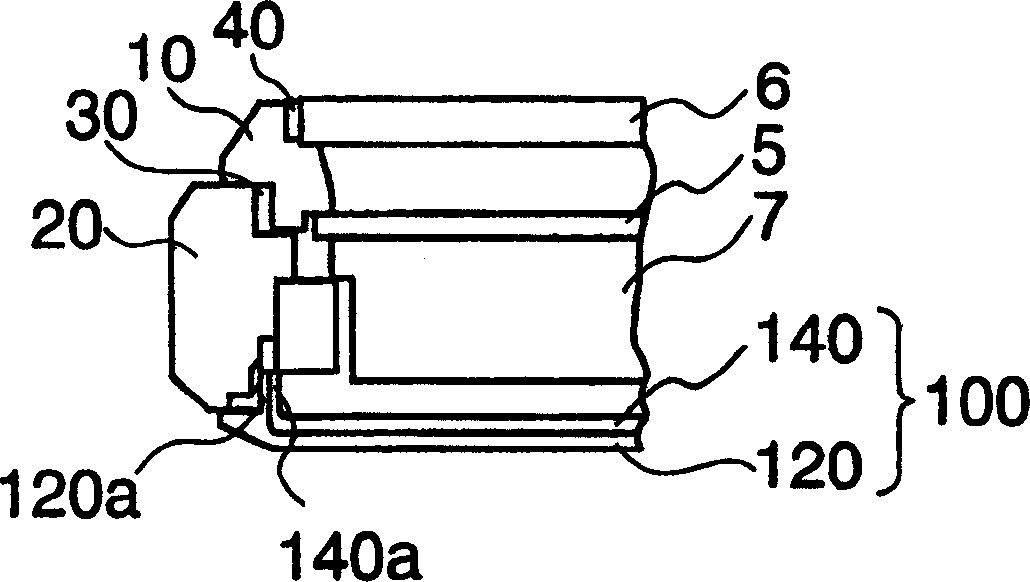

Embodiment 1

[0022] In order to solve the above problems, embodiments of the present invention will be described based on the drawings. Figure 1 shows a cross-sectional view of a timepiece with one or two layers of covering material in the case back. The case back cover 100 is made of a covering material. The covering material is composed of a soft magnetic material 140 and a non-magnetic material 120. The soft magnetic material 140 includes pure iron, silicon steel sheet, permalloy or ferrite One of stainless steel, and the above-mentioned non-magnetic material 120 includes one of titanium material or austenitic stainless steel. The outer side of the case back cover 100 in contact with the wearer's wrist is made of a non-magnetic material 120 , while the side of the movement 7 is a soft magnetic material 140 . The soft magnetic material 140 and the non-magnetic material 120 respectively form raised portions 120a, 140a at the boundary edges of the soft magnetic material 140 and the non-ma...

Embodiment 2

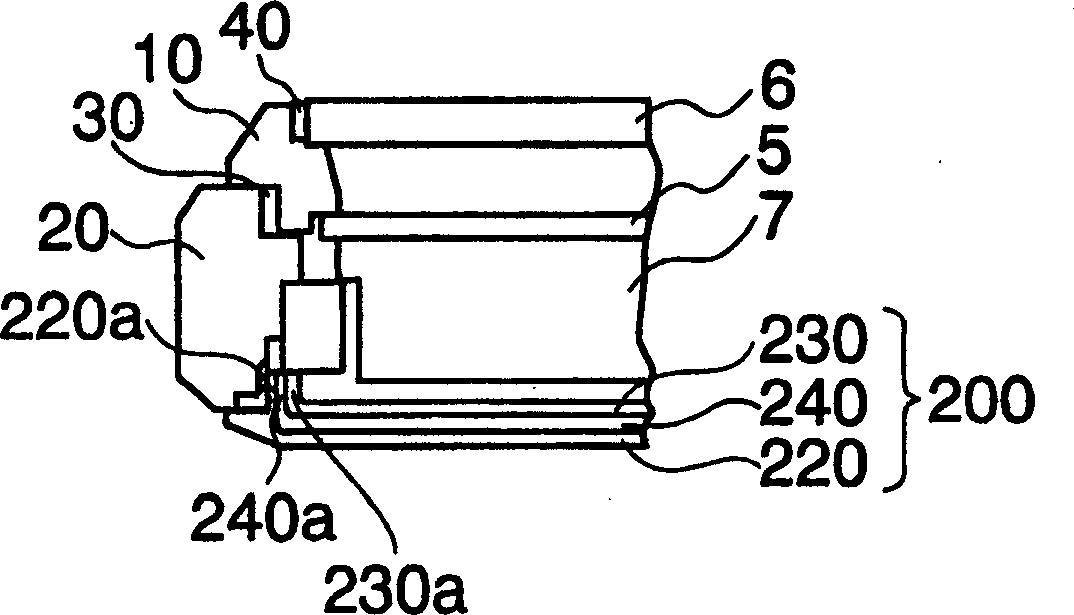

[0024] Fig. 2 is a cross-sectional view of a timepiece in which three layers of covering material are employed in the case back. A non-magnetic material 220 is arranged on the side of the case back cover 200 contacting the wearer's wrist, and a non-magnetic material 230 is also arranged on the side of the movement, and a soft magnetic material is sandwiched between the above two non-magnetic materials. Between the magnetic material 220,230. Both the non-magnetic material 220 on the wrist side and the non-magnetic material 230 on the movement side may be the same material, or may be different materials.

[0025] If a three-layer covering material in which the soft magnetic material 240 has been arranged in the middle is adopted, it also becomes unnecessary to add a corrosion-resistant coating because it has been covered by a titanium material or austenitic stainless steel inside, and it also becomes The cover can be made thinner by using pure iron, silicon steel sheet, permall...

Embodiment 3

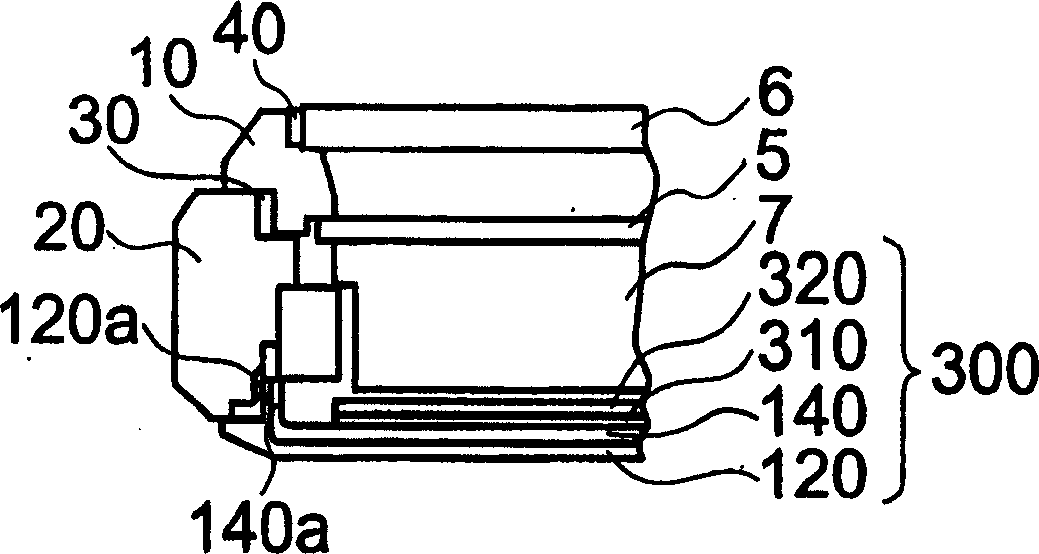

[0027] FIG. 3 shows a sectional view of a timepiece using a case back 300 in which a vibrating plate 320 is bonded to the case back 100 used in Embodiment 1. Referring to FIG. The vibrating piece 320 is bonded and fixed to the surface of a soft magnetic material 140 by applying an adhesive 310 . The vibrating plate 320 vibrates by a signal from the movement, thereby emitting a sound such as an alarm. Since the other parts are the same as those of Embodiment 1, description thereof will be omitted.

[0028] Next, FIG. 4 shows the conditions under which the experiment was actually performed and the experimental results thereof. Manufactured an antimagnetic case back for wristwatches meeting the conditions for Class I diving watches for use at a water depth of 100m as specified in JIS B7024 "Waterproof watches for diving - Types and performance", And the conditions of the second class of antimagnetic watches as specified in JIS B7024 "Antimagnetic watches". In order to minimize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com