Trimeric cyanamide joint production method using one step method

A melamine and step method technology, applied in the field of one-step melamine co-production, can solve the problems of long equipment life, high consumption of raw materials and energy, and low labor intensity, and achieve the effects of good product quality, low raw material consumption, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

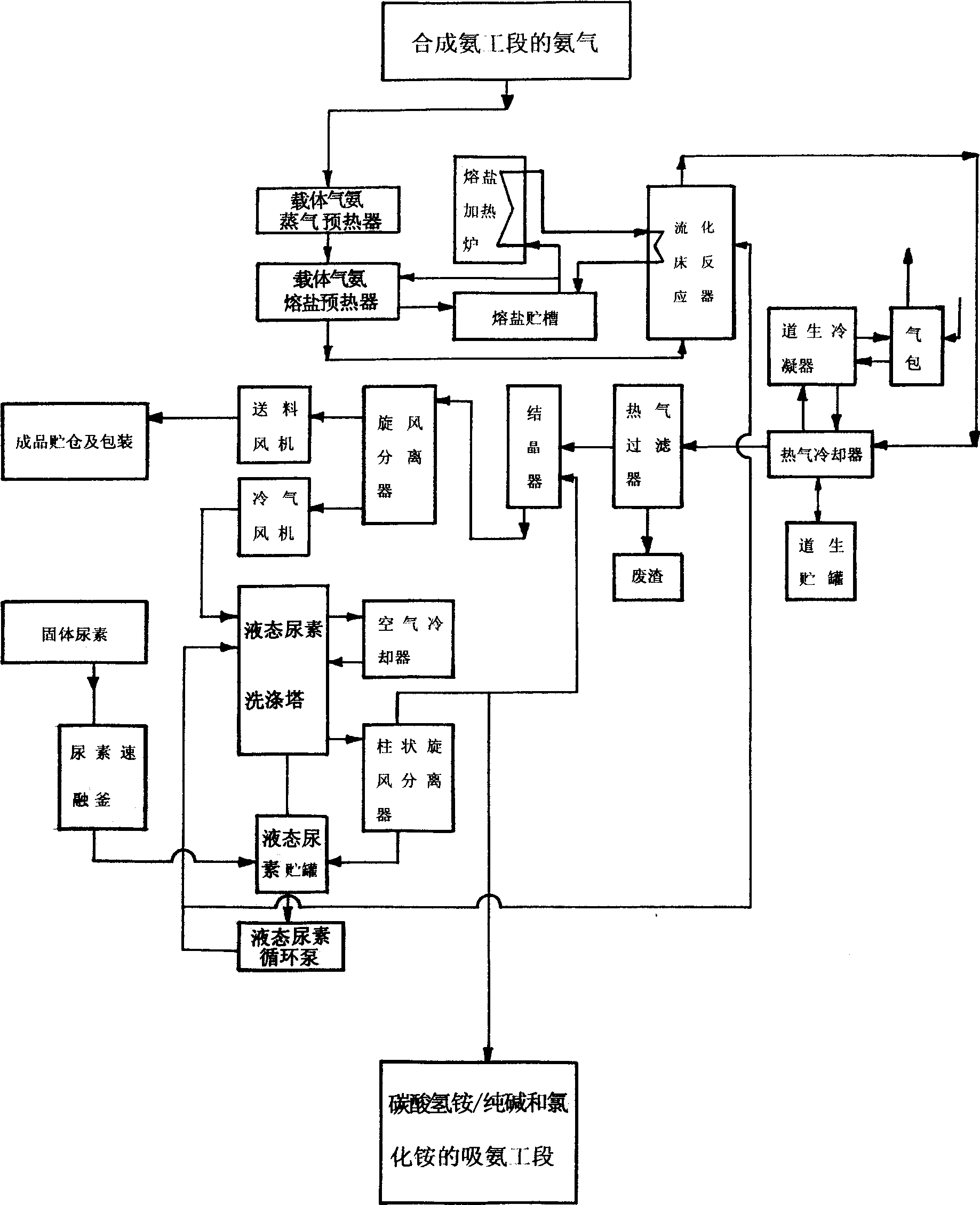

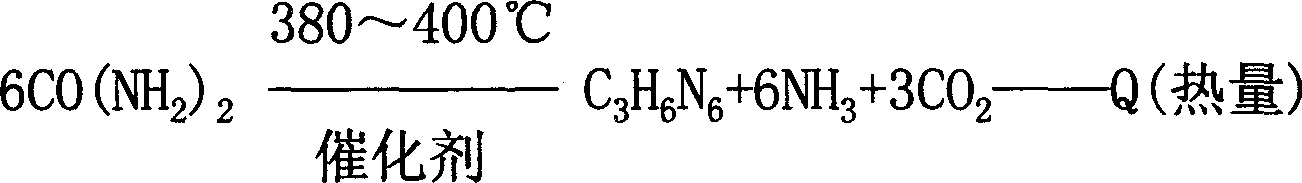

[0019] Embodiment 1, with reference to accompanying drawing, directly select the ammonia gas that comes over from synthetic ammonia workshop section, pressure 0.10~0.15MPa, temperature is 0~5 ℃, every production 1 ton of melamine needs 4400~4800 kilograms of ammonia gas, through carrier gas ammonia vapor The preheater is preheated to 150°C, the pressure is 0.10-0.15MPa, and then heated to 350-400°C by the carrier gas ammonia molten salt preheater; then it enters the fluidized bed reactor as the carrier gas ammonia of the fluidized bed. When the fluidized bed reaction temperature is 380-400°C, the liquid urea branched from the liquid urea circulation pump enters the fluidized bed reactor, and 3.05-3.15 tons of liquid urea is needed to produce 1 ton of melamine. Under the action of catalyst silica gel 60-70 grams of urea can be cast per kilogram of silica gel, and melamine gas is generated through a series of reactions; the melamine-containing gas reacted from the fluidized bed i...

Embodiment 2

[0020] Embodiment 2, with reference to accompanying drawing, directly select the ammonia gas that comes over from synthetic ammonia workshop section, pressure 0.10~0.15MPa, temperature is 0~5 ℃, every production 1 ton of melamine needs 4400~4800 kilograms of ammonia gas, through carrier gas ammonia vapor The preheater is preheated to 150°C, the pressure is 0.10-0.15MPa, and then heated to 350-400°C by the carrier gas ammonia molten salt preheater; then it enters the fluidized bed reactor as the carrier gas ammonia of the fluidized bed. Under the condition that the fluidized bed reaction temperature is 380-400°C, the liquid urea branched from the liquid urea circulation pump enters the fluidized-bed reactor, and 3.05-3.15 tons of liquid urea is needed for every ton of melamine produced. Under the action, 60-70 grams of urea can be cast per kilogram of silica-alumina glue, and melamine gas is generated through a series of reactions; the melamine-containing gas reacted from the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com