Mounting structure of start motor

A technology of starting motor and installation structure, which is applied to the starting of the engine, the starting device with a mechanical power storage, the starting of the motor for the engine, etc. issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

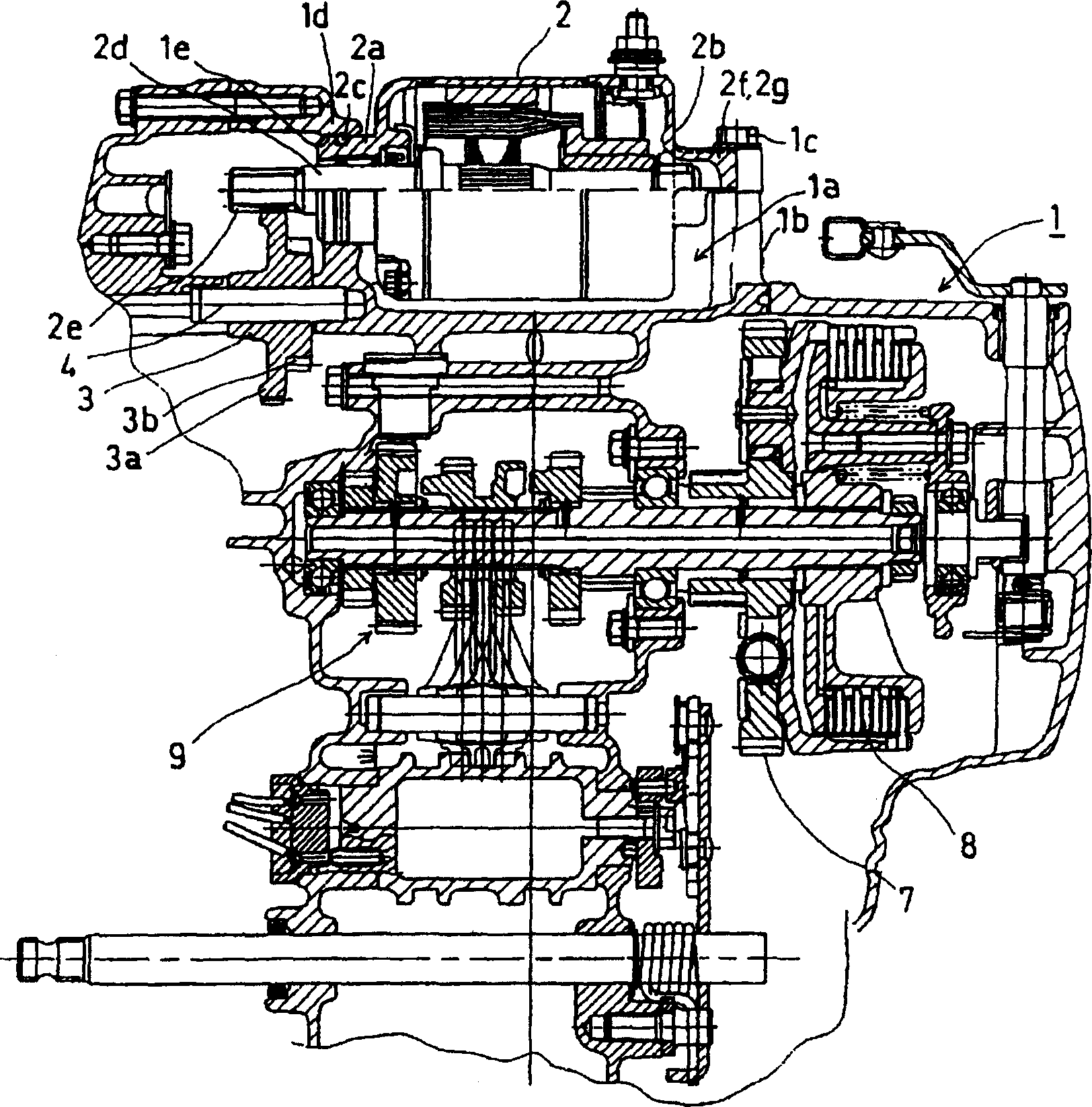

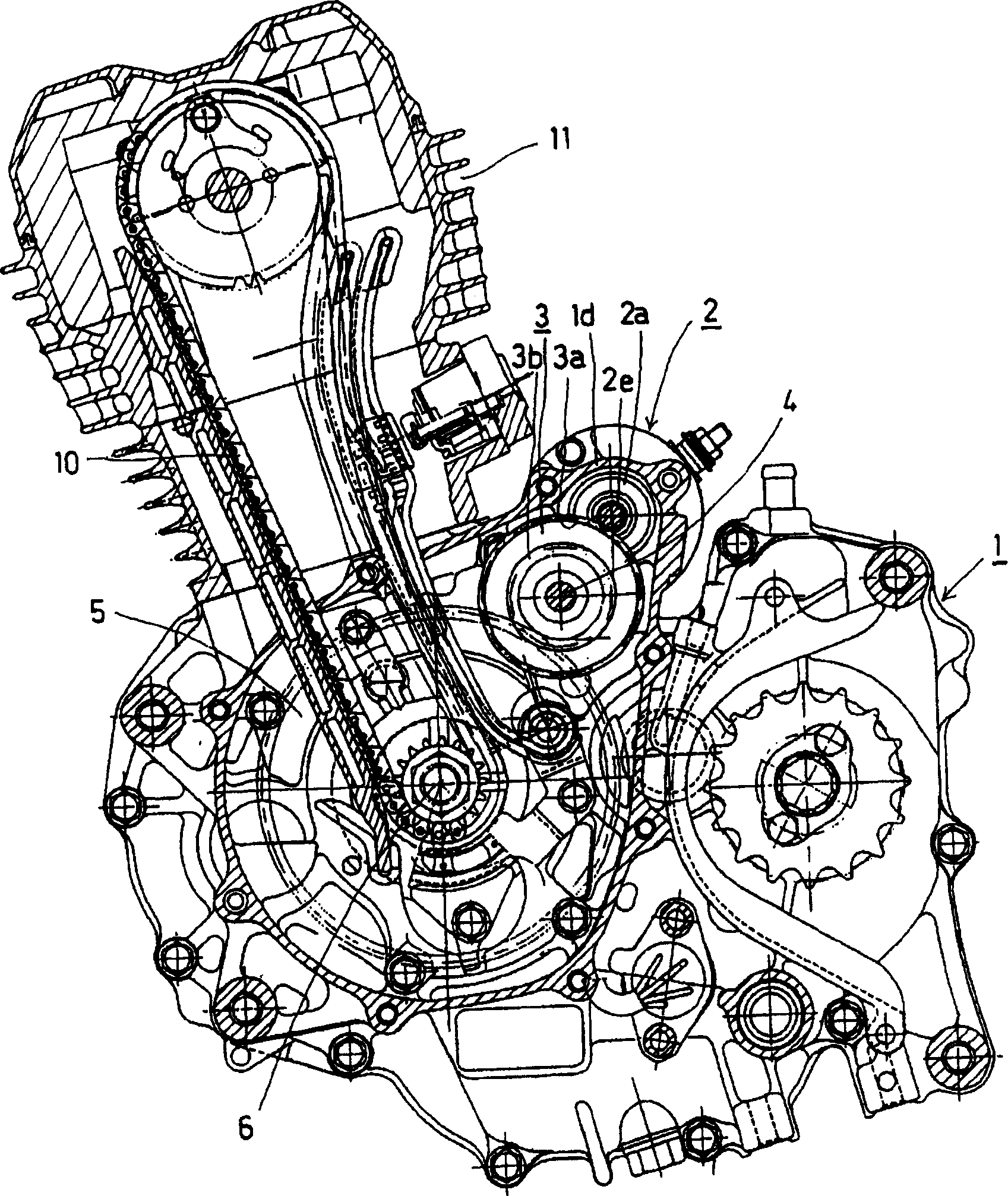

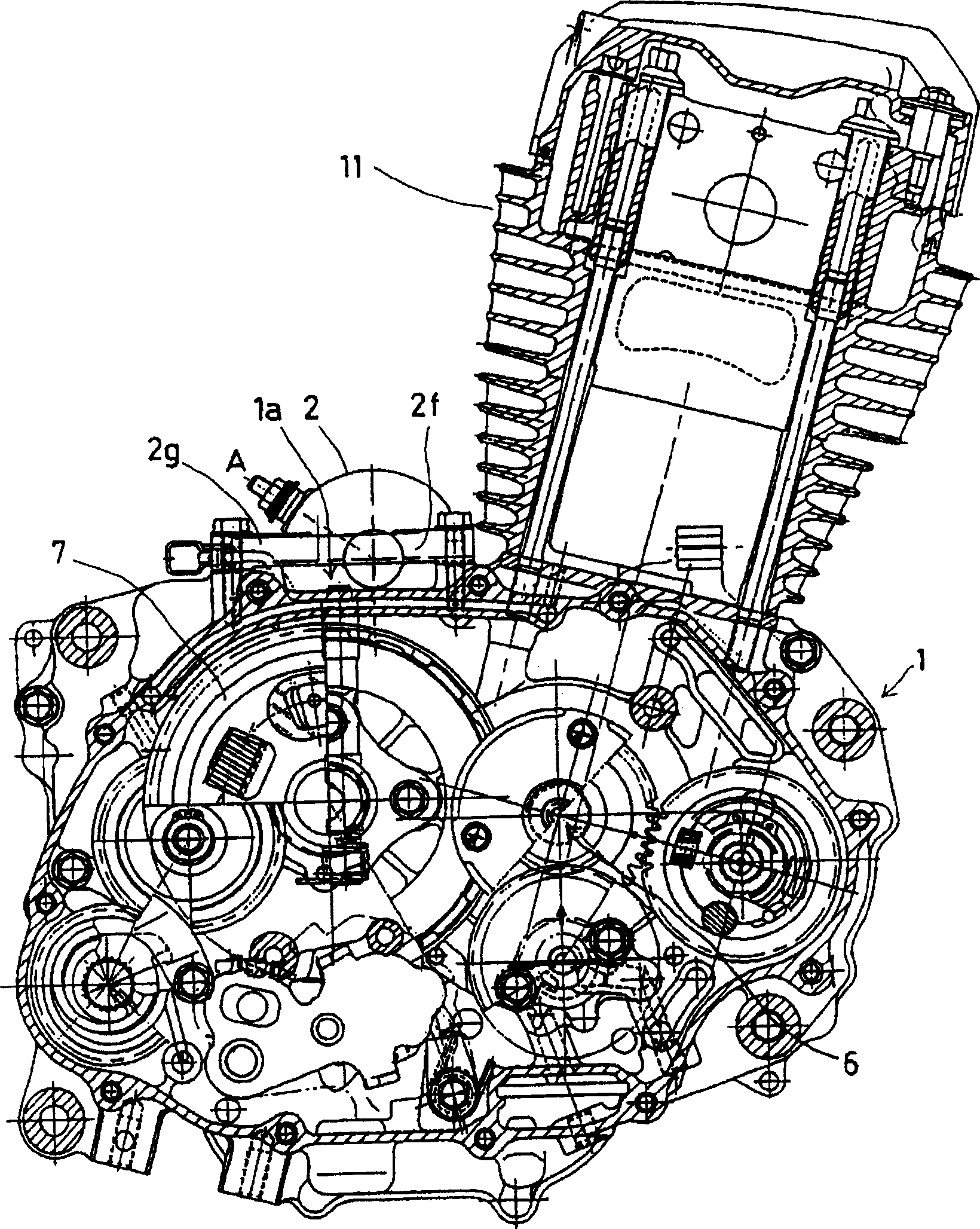

[0022] Below, according to Figure 1 to Figure 4 Embodiments of the present invention will be described.

[0023] figure 1 Represents a longitudinal sectional view in the direction of a crankshaft (not shown) of a crankcase 1 in an internal combustion engine, in which figure 1 In the figure, the partial structure of the crankcase 1 is shown, and in this figure, the starter motor 2 and its surrounding structural parts which are the characteristic structural part of this invention are described.

[0024] Also, an intermediate gear 3 and the like meshed with a gear 2e integral with the rotating shaft 2d of the above-mentioned starter motor 2 are shown, and the intermediate gear 3 is connected to the figure 1 The driven gear 5 on the side of the crankshaft 6 not shown is meshed, and the rotational driving force of the above-mentioned starter motor 2 is transmitted to the above-mentioned crankshaft 6 via the above-mentioned intermediate gear 3 (refer to figure 2 ).

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com