Dual-clutch transmission for vehicle

A transmission and clutch technology, which is applied in the direction of vehicle gearboxes, vehicle components, gear transmissions, etc., to achieve the effect of shortening the axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

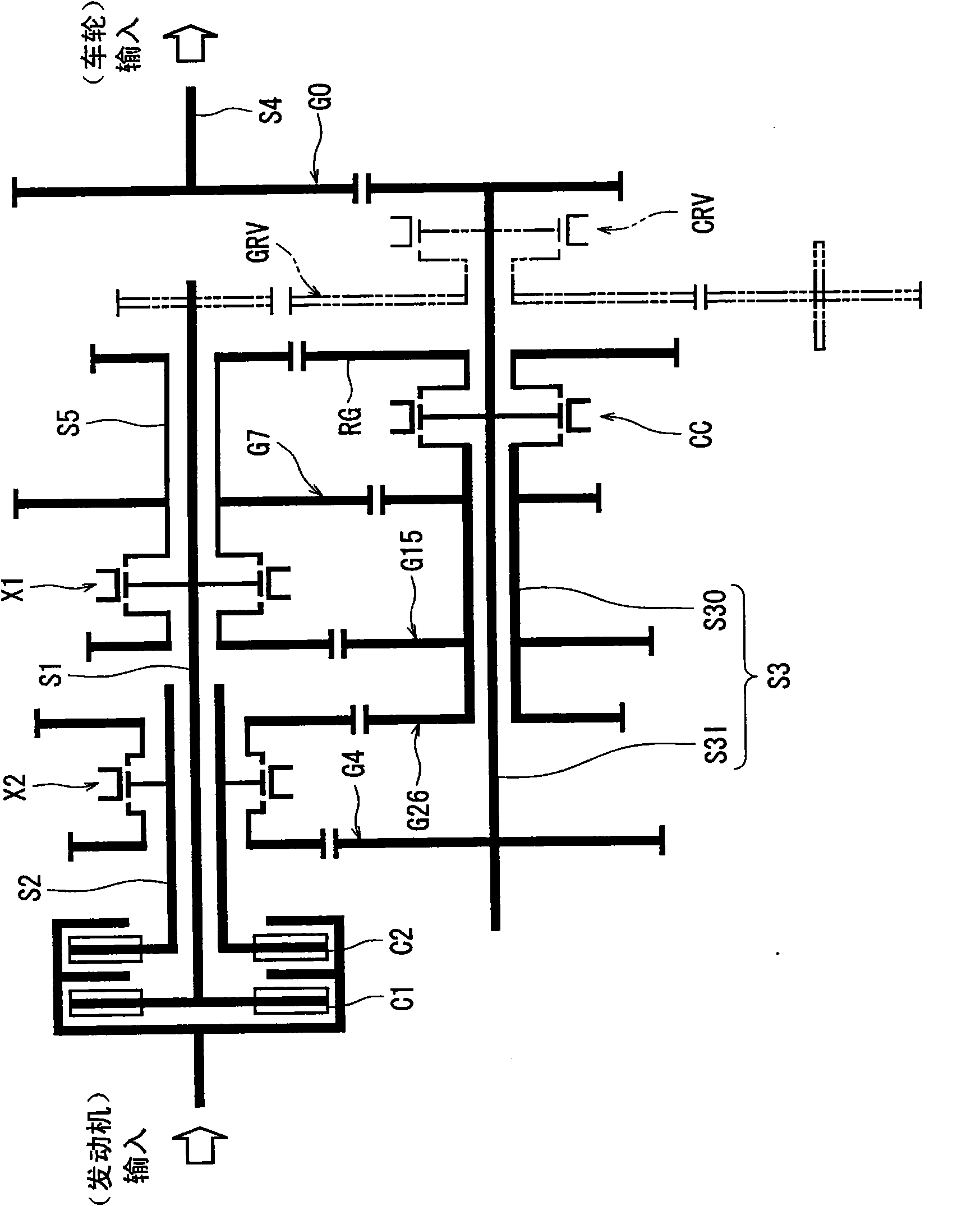

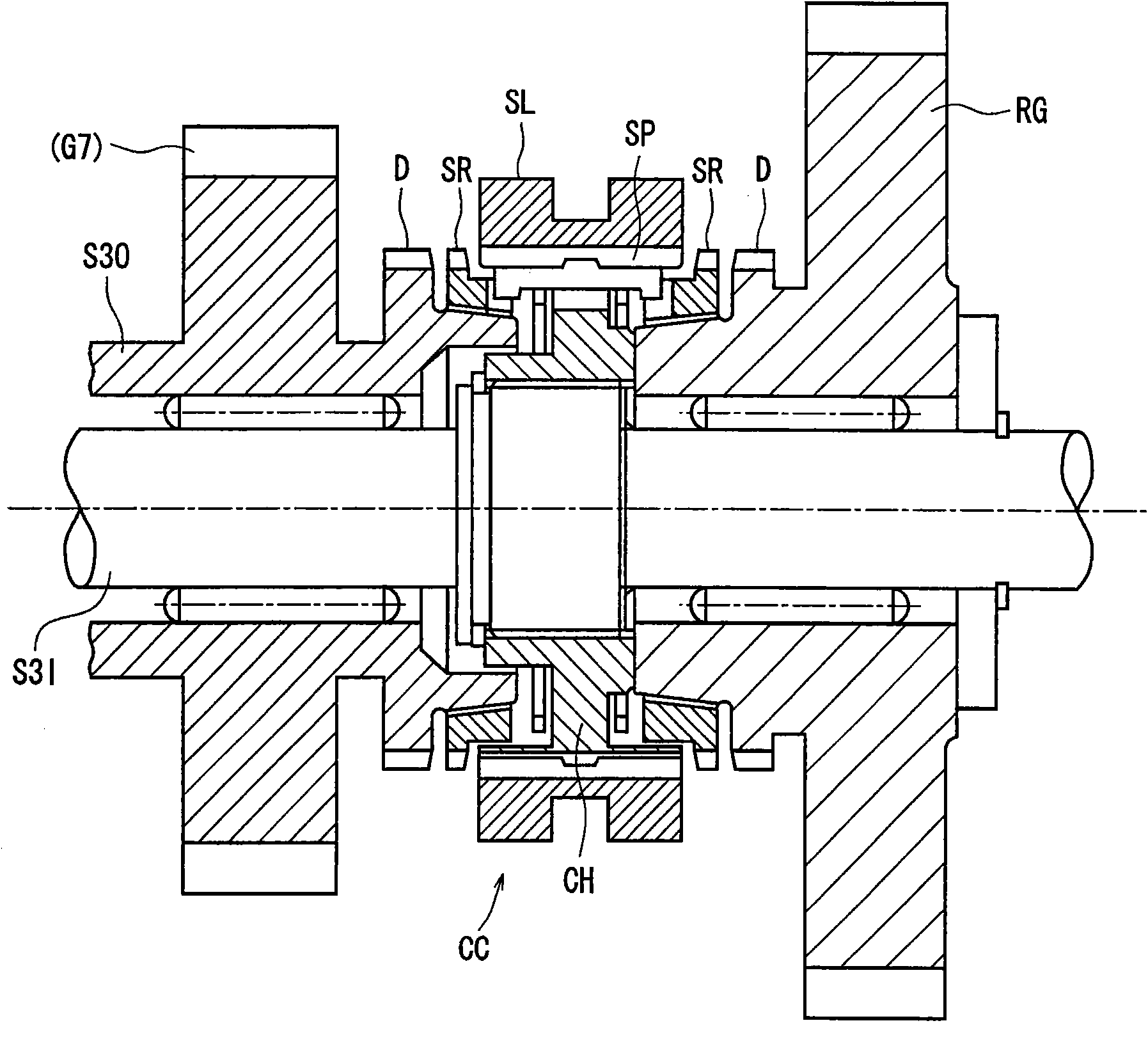

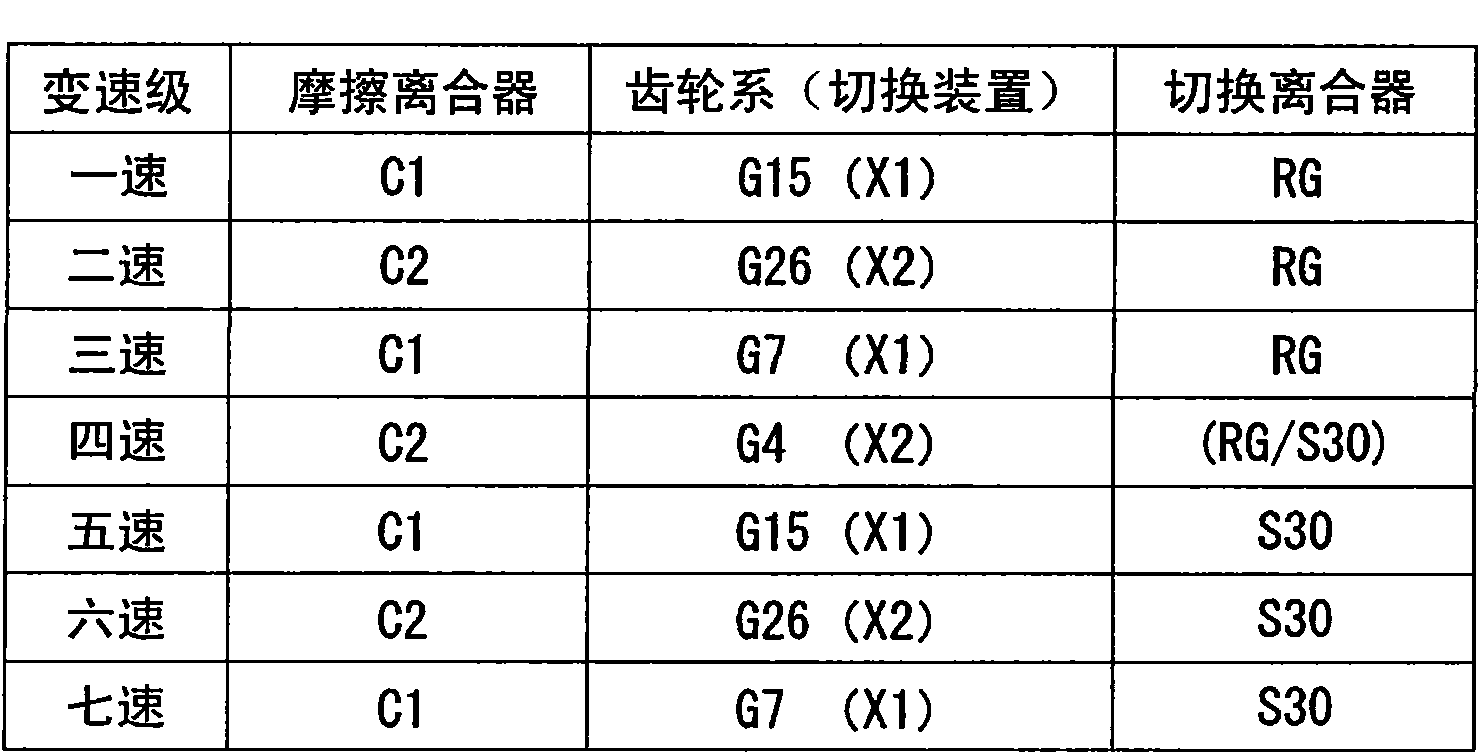

[0057] Hereinafter, the dual-clutch transmission of the present invention will be described based on the drawings. figure 1 It is a schematic diagram showing an embodiment of the dual-clutch transmission of the present invention, figure 2 It is a figure showing the structure of the switching clutch provided on the intermediate shaft. exist figure 1 in, right with Figure 11 Corresponding components such as those in the conventional dual-clutch transmission are denoted by the same reference numerals.

[0058] Such as figure 1 As shown, in the dual-clutch transmission of this embodiment, a first input shaft S1 and a second input shaft S2 formed in a double pipe structure are arranged, and the first input shaft S1 penetrates through the hollow second input shaft S2 and extends rearward. A first friction clutch C1 and a second friction clutch C2 arranged in parallel in the axial direction are arranged in front of the two input shafts, and the input side of each friction clu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com