Foreign matter removing mechanism, foreign matter removing method, printing device and printing method

A technology of a printing device and a printing method, which can be applied to projection devices, cameras, projectors with built-in screens/external-mounted screens, etc., can solve the problems of easily rolling in foreign objects, increase manufacturing costs, etc., to suppress adhesion and reduce charging bias. , the effect of reducing the charged gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] An embodiment of the present invention will now be described.

[0112] The printing device (this printing device) of this embodiment is a printing device of an electronic imaging system that prints an image corresponding to image data on paper (printing paper) using a two-component developer including toner and a carrier. . In addition, the developing method of this printing device is reverse developing.

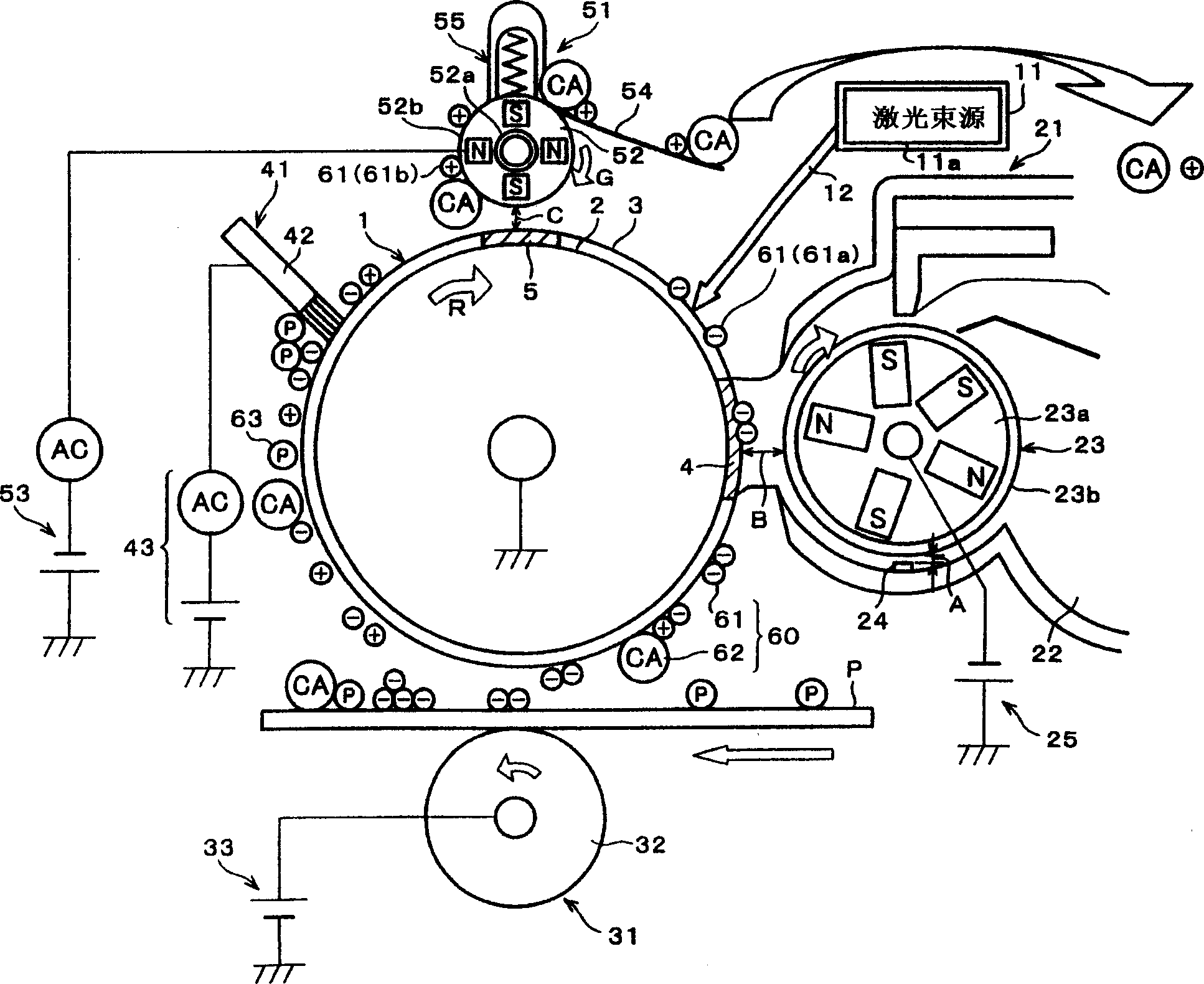

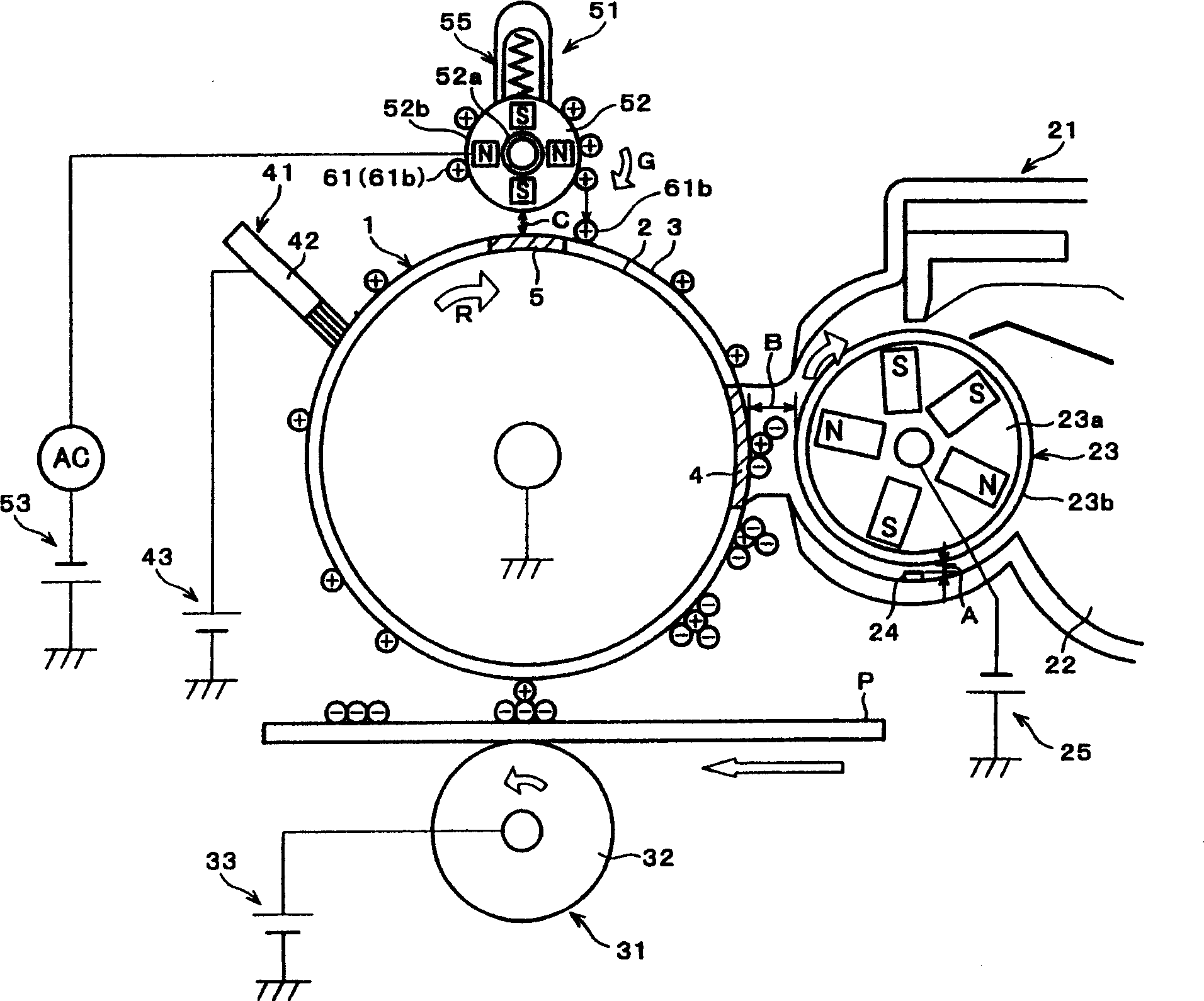

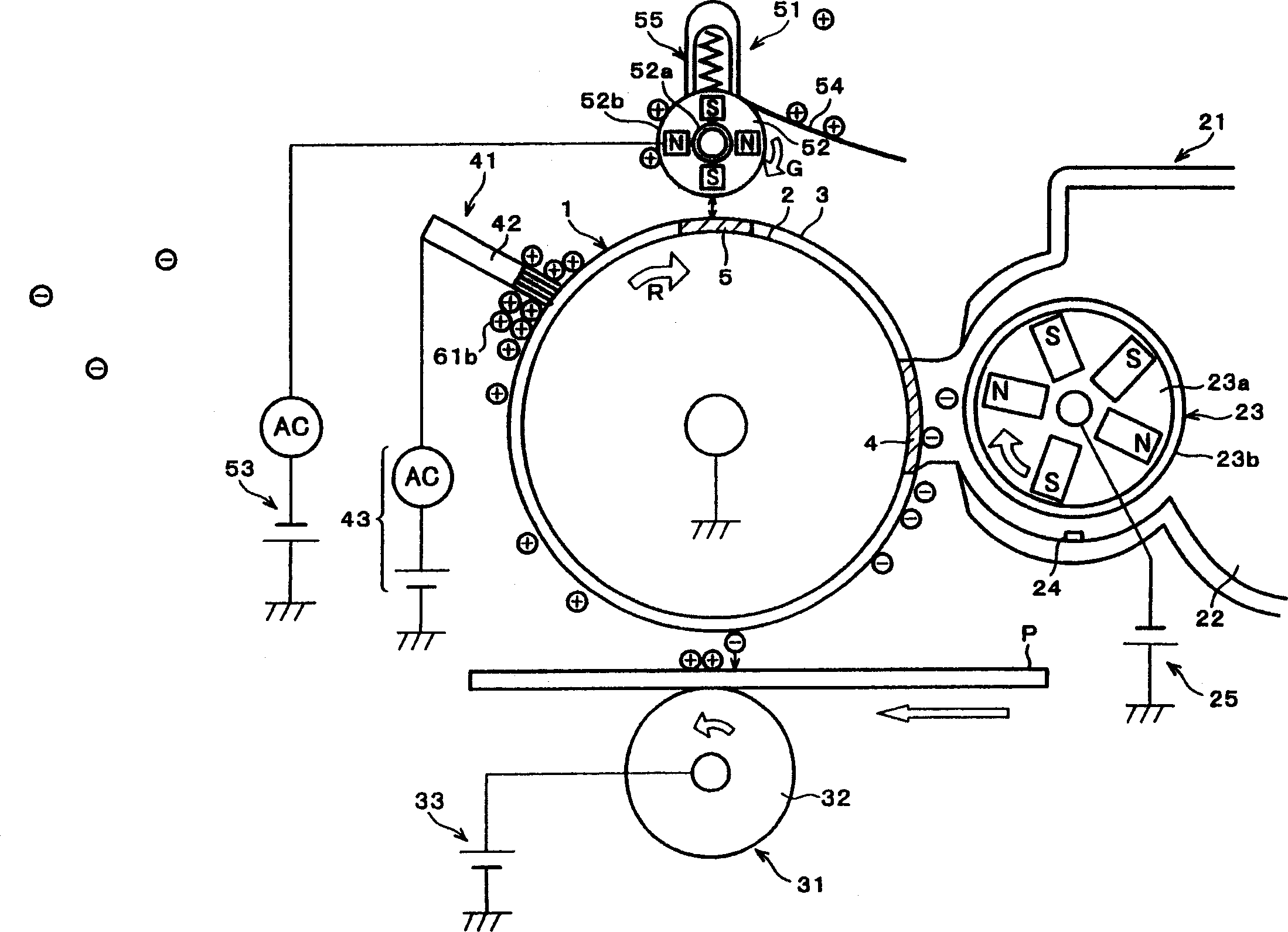

[0113] figure 1 It is an explanatory diagram showing the configuration of this printing apparatus.

[0114] As shown in the figure, the structure of this printing apparatus is: around the photoreceptor 1, starting from the exposure position (irradiation position where the laser light 12 is emitted from the LSU11), along the rotation direction of the photoreceptor 1, the LSU11, the developing device 21 , transfer device 31 , foreign matter stirring device 41 , and charging device 51 .

[0115] The photoreceptor (image holder) 1 is a photoreceptor drum rotationally...

Embodiment 2

[0604] Another embodiment of the present invention will be described below.

[0605] In the above-mentioned Embodiment 1, a printing apparatus employing a two-component development method in which a two-component developer containing the toner 61 and the carrier 62 is used was exemplified. In this embodiment, a printing apparatus adopting a one-component developing method, in which a one-component developer not containing the carrier 62 is used, is exemplified instead of a two-component developing method. In this embodiment, differences from the first embodiment described above are mainly described. For the convenience of description, the same reference numerals are given to components having the same functions as those in the first embodiment, and their descriptions are omitted.

[0606] Figure 15 It is an explanatory diagram showing the configuration of the printing apparatus (this printing apparatus) of this embodiment. As shown in the figure, in this printing apparatus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com