Method and device for monitoring operation of plain bearing

A technology for sliding bearings and sliding surfaces, applied in sliding contact bearings, bearings with rotating motion, bearings, etc., can solve problems such as unreliable temperature estimation and incorrect measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

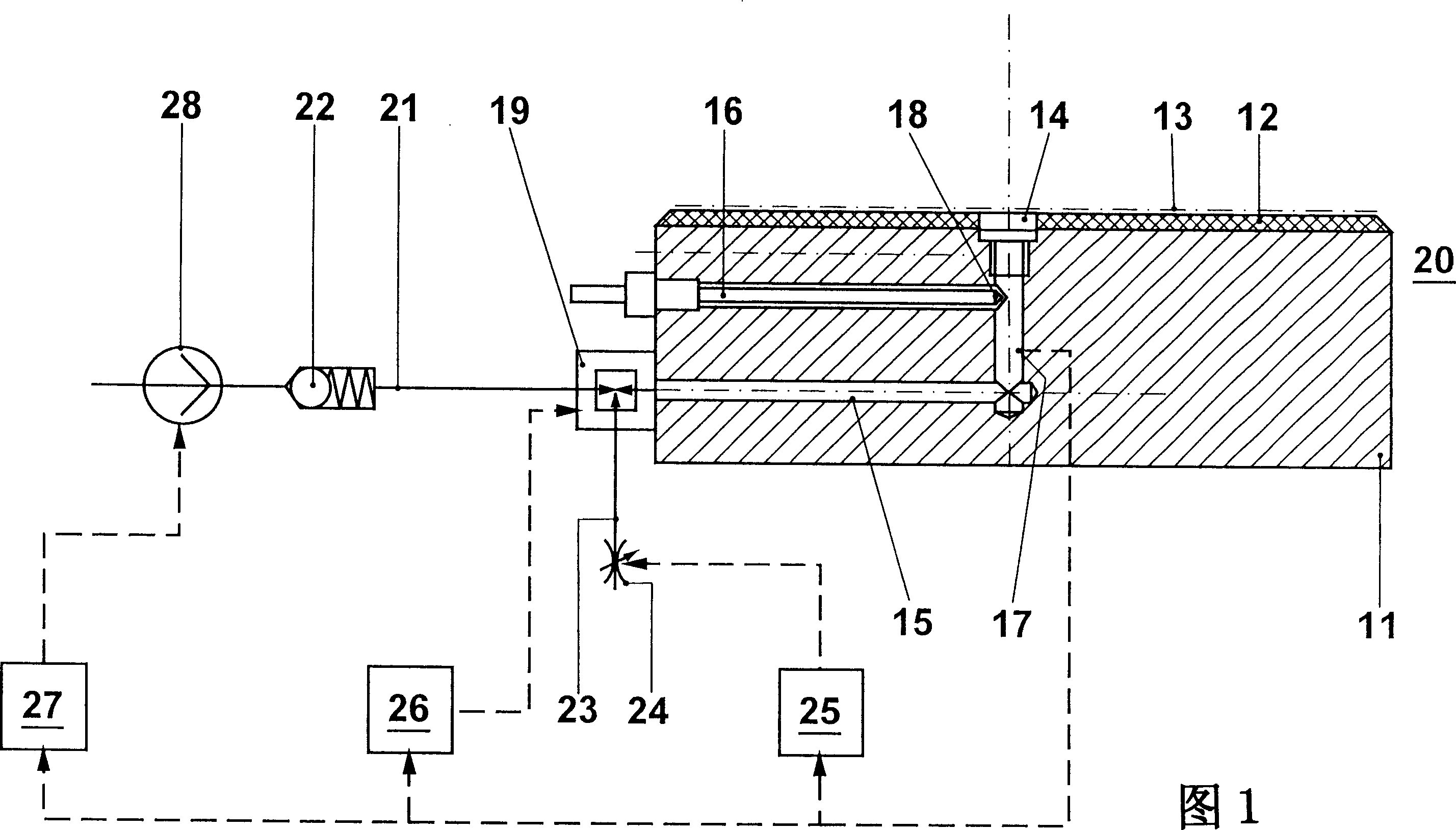

[0013] A bearing section of a hydrodynamic plain bearing with lubricating film temperature monitoring according to a preferred embodiment of the invention is shown in the drawing. The hydrodynamic plain bearing 20 of this figure consists of several bearing segments, of which only bearing segment 11 is shown, which is provided with a high-pressure lubrication system, for example an oil lifting device, which is not completely represented by a pump 28 . Such a bearing segment is arranged in particular in the lower region of the bearing. An adequate hydrodynamic lubrication film cannot be built up when the shaft supported in the bearing is at low speeds. Oil lifting devices of this type are therefore only used in heavily loaded bearings. First, before the shaft is started, the lubricant is pressed by the high-pressure pump 28 into the bearing gap (not shown) through the lubricant channel 15 in the standstill state, and the load to be supported is lifted ideally from the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com