Glass panel based chip type LCD device

A liquid crystal display device, chip-type technology, applied in identification devices, static indicators, optics, etc., can solve problems such as drive circuits not working properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

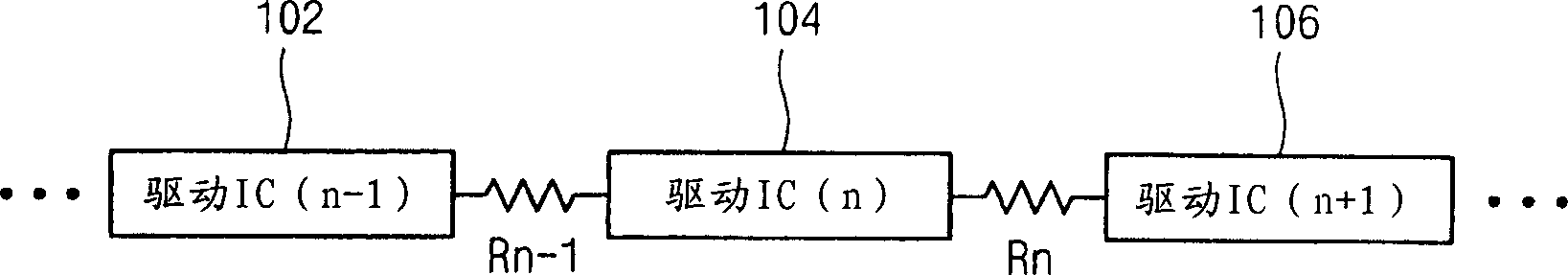

[0023] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings. In order to maintain the consistency of description, the same reference symbols are used in the drawings to indicate the same or similar structural elements and signals.

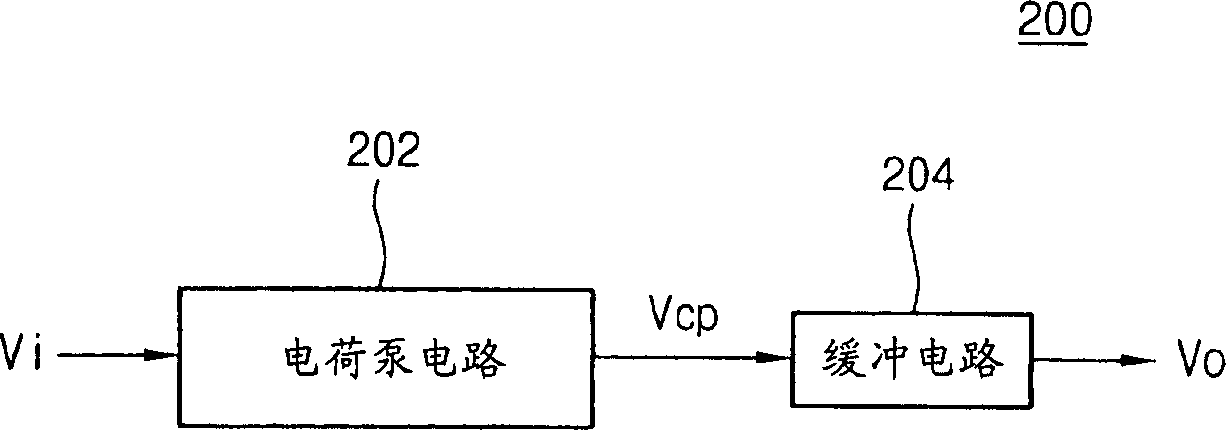

[0024] figure 2 is a block diagram of a driving voltage generating section according to an embodiment of the present invention. Such as figure 2 As shown, each driver IC has a driving voltage generating unit 200 composed of a charge pump circuit 202 and a buffer circuit 204 .

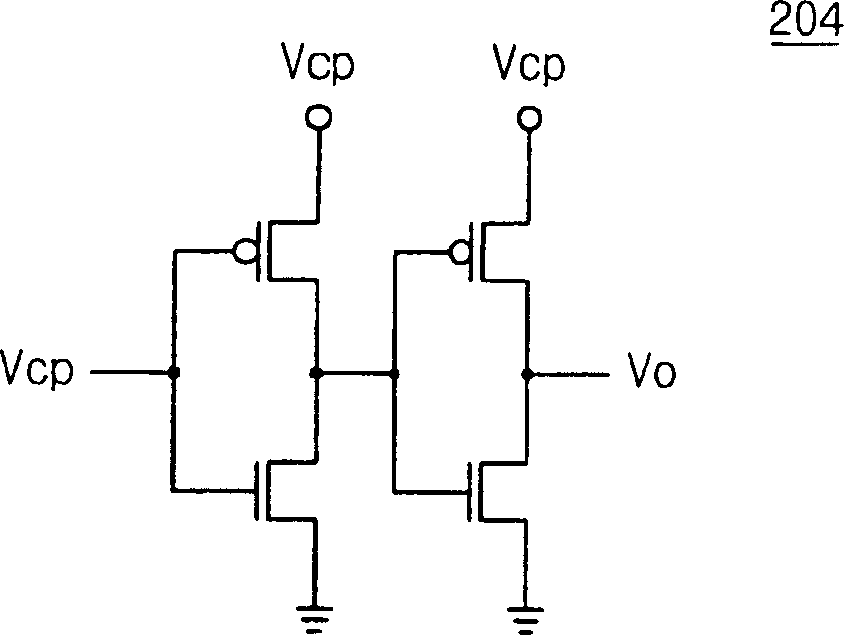

[0025] The charge pump circuit 202 boosts the driving voltage (Vi) applied from the front-end driver IC to a predetermined level and outputs a voltage (Vcp). The charge pump circuit 202 is well known in the industry, so its specific structure will not be described here. The buffer circuit 204 stabilizes the voltage (Vcp) output from the charge pump circuit 202 to generate a voltage (Vo)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com