Output component structure for magnetron

A technology of output components and magnetrons, which is applied in the field of magnetrons, can solve the problem of low attenuation ability of the third high-frequency wave, and achieve the effect of improving attenuation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

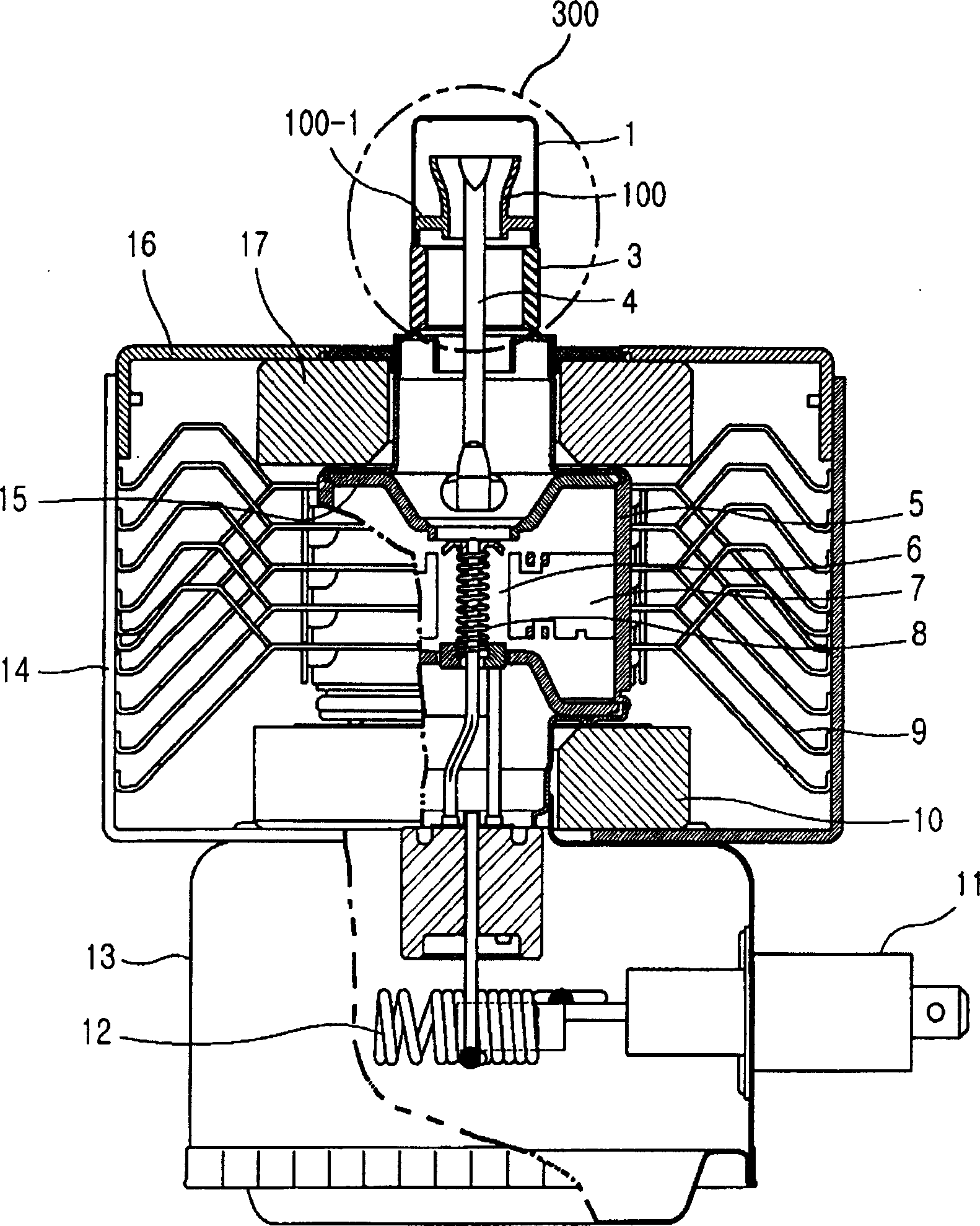

[0037] Refer to the attached Figure 3-7, the embodiment of the structure of the magnetron output part that improves the attenuation capability of the third high-frequency band by adjusting the length of the exhaust pipe of the magnetron output part of the present invention will be described in detail.

[0038] image 3 A cross-sectional view of a magnetron of the present invention is shown.

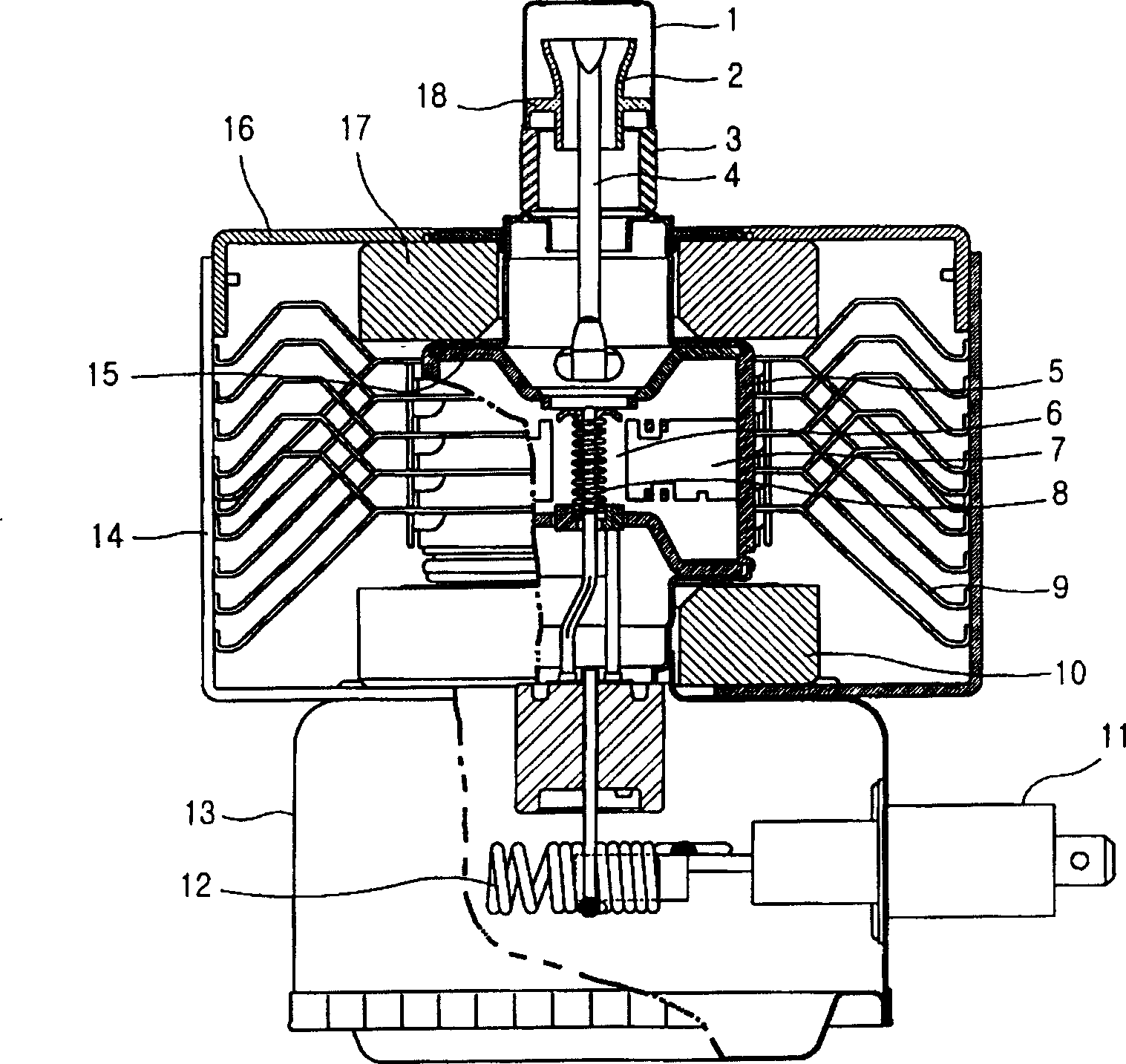

[0039] Such as image 3 As shown, the magnetron generally includes a series cathode 8, an anode 5, an action space 6, an upper yoke 16 and a lower yoke 14, a permanent magnet 10 and a permanent magnet 17, a magnetic pole 15, a plurality of blades 17 and a cooling fin 9. The above-mentioned serial cathode is a structure with a filamentous cathode in the center of the interior; the above-mentioned anode 5 is an anode structure arranged around the above-mentioned cathode 8; the above-mentioned working space 6 is formed between the above-mentioned cathode 8 and the above-mentioned anode 5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com