Jump sewing mechanism for sewing machine

A sewing machine and jump stitch technology, applied in the field of sewing machines, can solve the problems of complex structure and complicated operation of the jump stitch mechanism, and achieve the effects of avoiding complicated structure, simple operation and eliminating impact sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

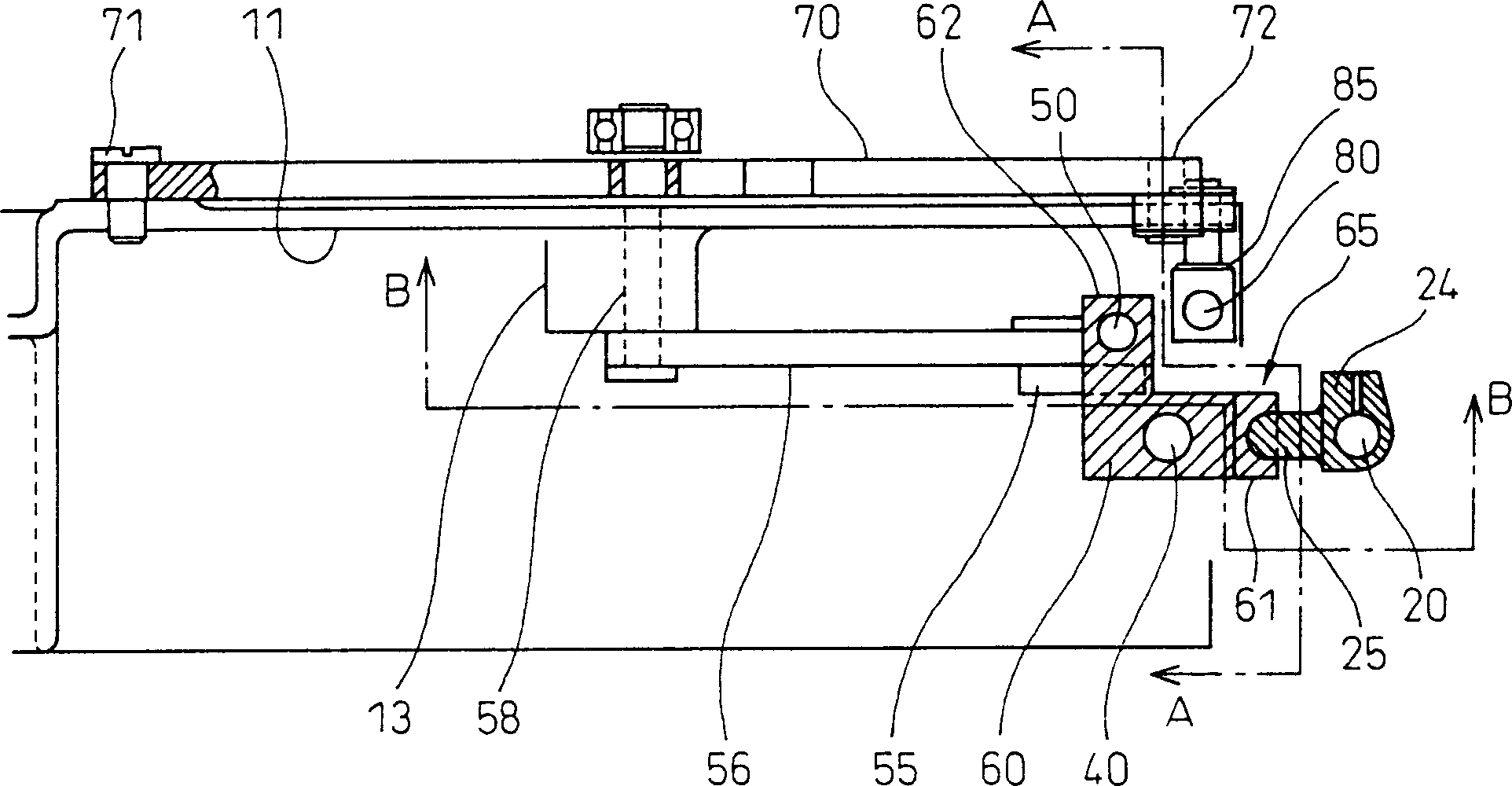

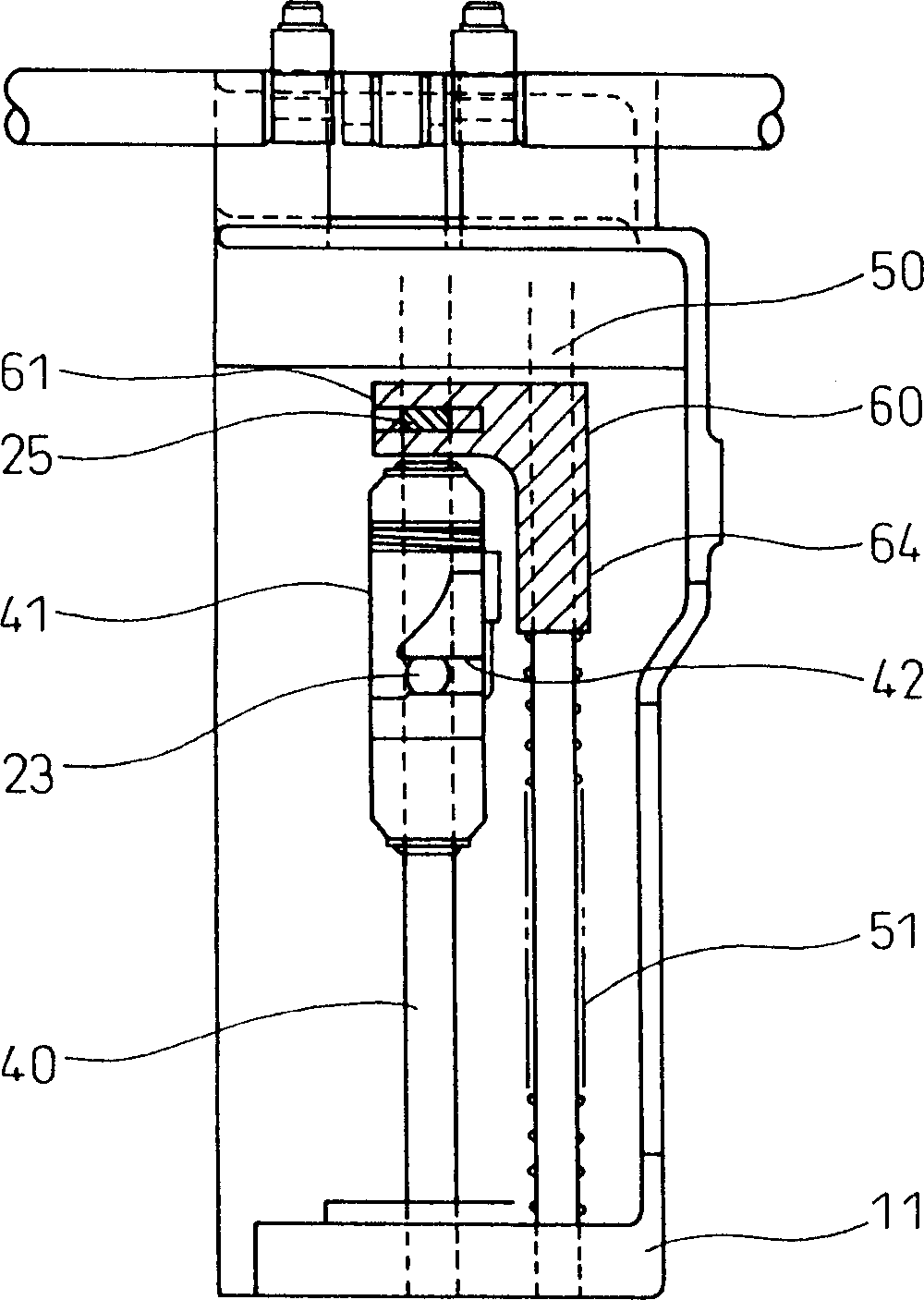

[0017] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the following figures, the same reference signs are used for the same components. For ease of understanding, the scales of the drawings are appropriately changed in scale and some components are omitted.

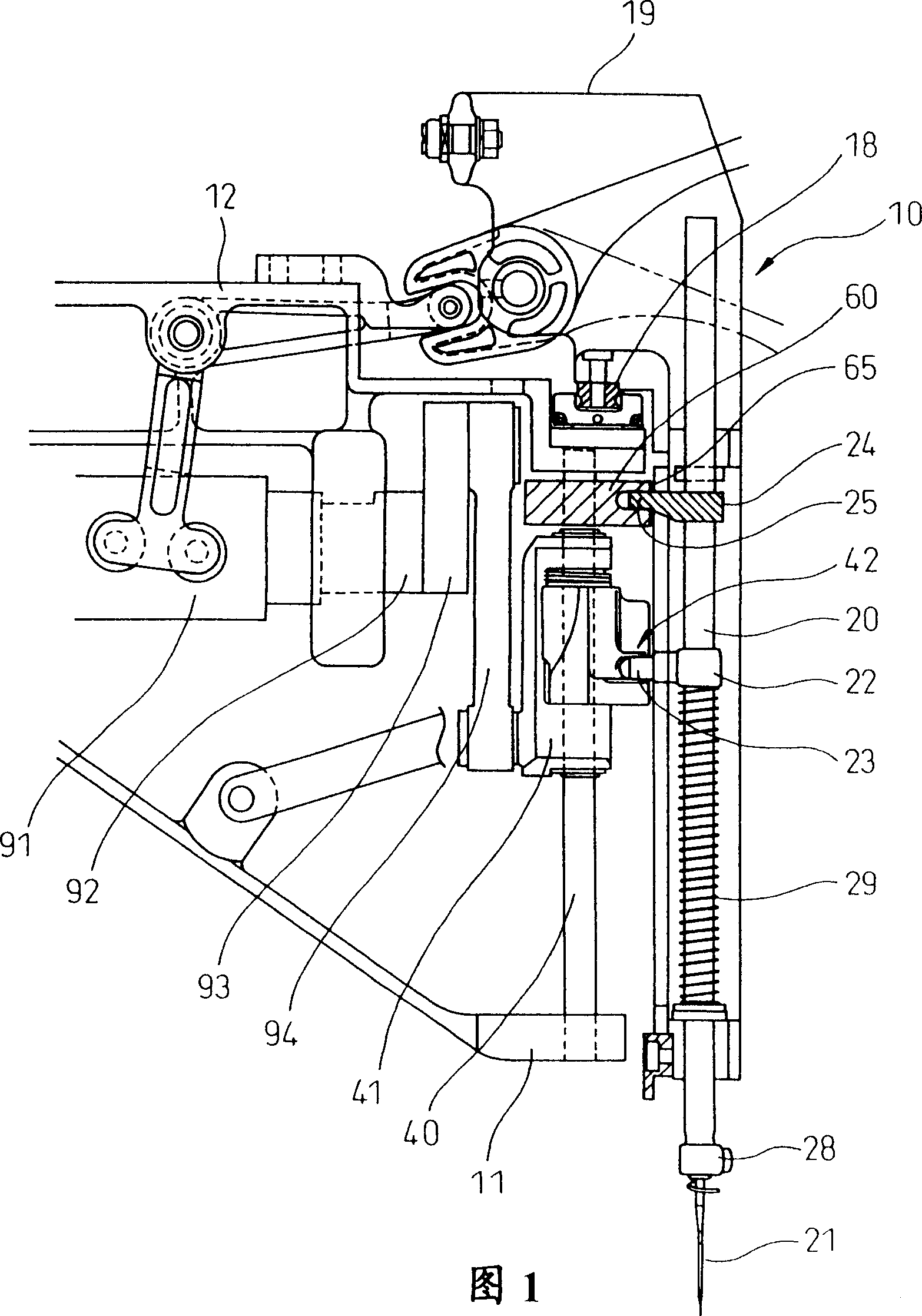

[0018] Fig. 1 is a partial side view viewed from one side when a skipping mechanism portion for a sewing machine according to the present invention is located at the top dead center position. In FIG. 1 , which shows a part of a sewing machine such as an embroidery sewing machine, a support case 19 is slidably provided in a horizontal direction on a frame 18 provided on an upper case 12 of the sewing machine. A plurality of needle bars 20 are arranged in the support case 19 , and a specific needle bar 20 can be selectively driven by moving the support case 19 along the frame 18 .

[0019] As shown in FIG. 1 , a jumper mechanism unit 10 of a sewing machine such as an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com