Torque control method for power rotary tool

A technology of electric rotation and torque control, applied in the direction of manufacturing tools, wrenches, wrenches, etc., can solve the problem of reducing the torque control accuracy of the torque setting mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

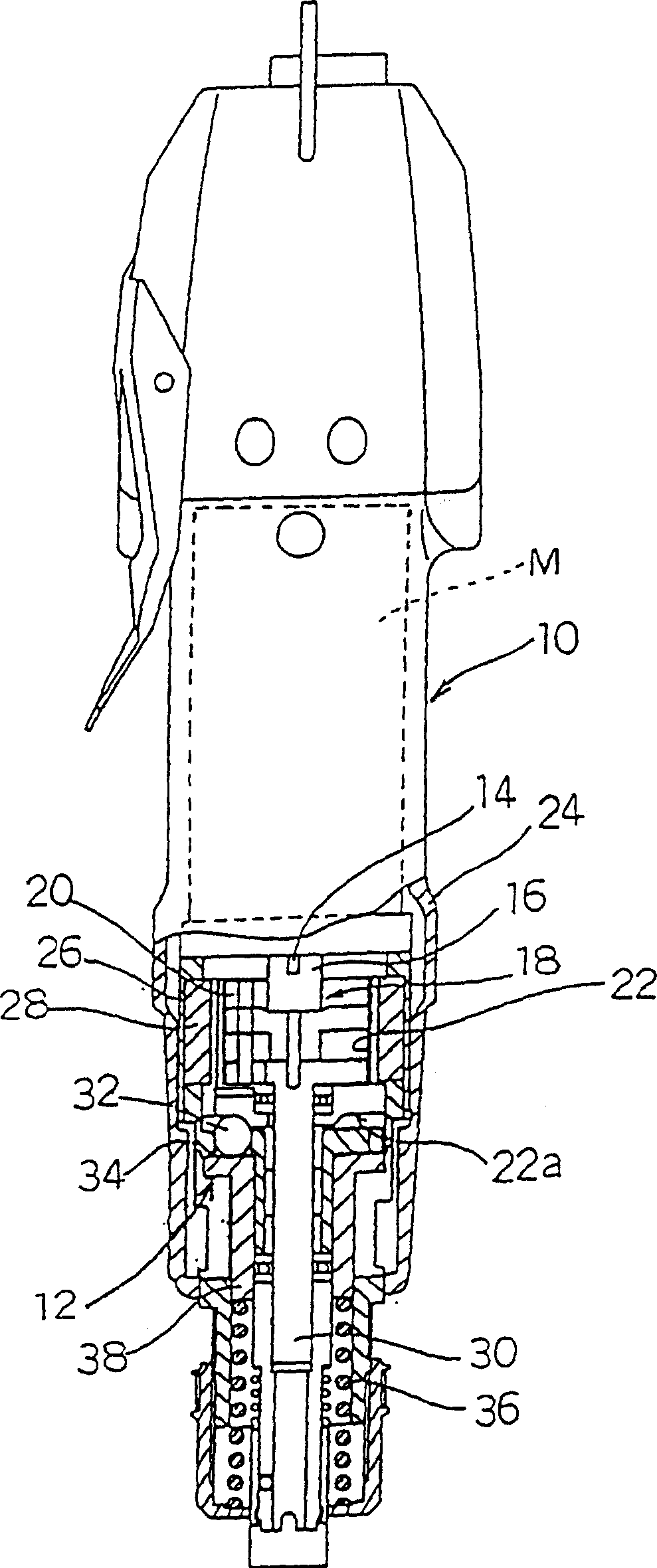

[0030] Next, an embodiment of the torque control mode of the electric rotary tool of the present invention will be described in detail below with reference to the accompanying drawings.

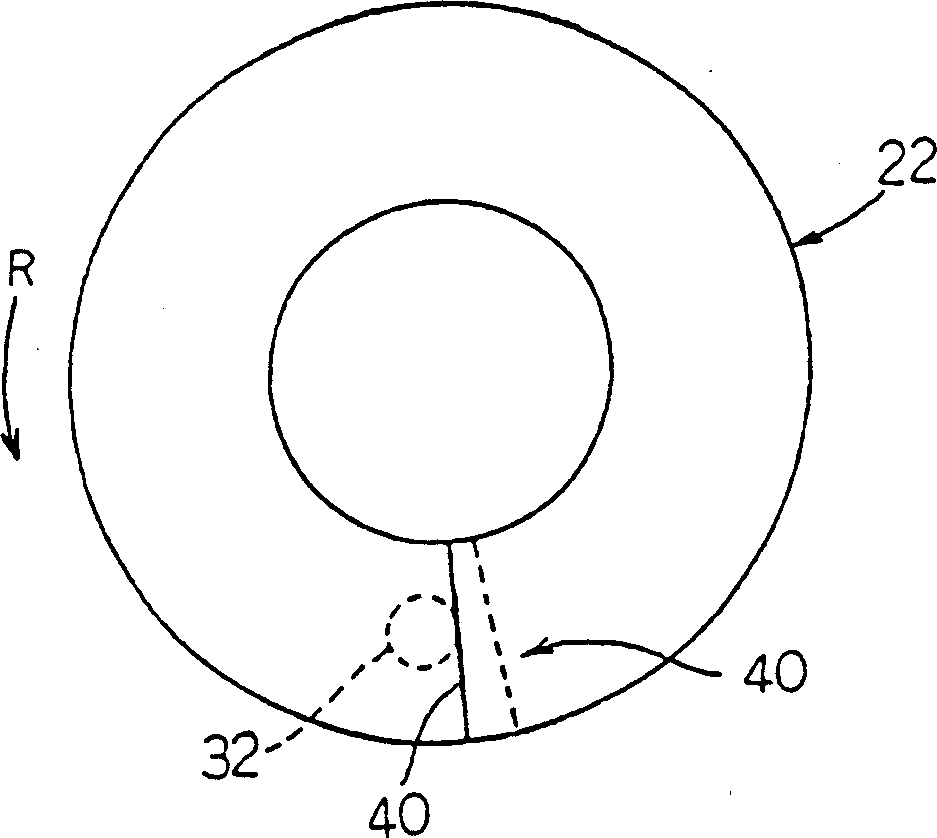

[0031] figure 1 Shown is a schematic cross-sectional view of main parts of an embodiment of an electric rotary tool implementing the torque control method of the present invention. That is, in figure 1 Among them, reference numeral 10 represents an electric rotary tool such as an electric drive such as an electric driver in which an electric motor M composed of a brushless motor or the like is built in. A pinion 16 is fixed at the front end of the output shaft 14 of the above-mentioned electric motor M, and the pinion 16 is meshed and connected by The reduction mechanism constituted by the planetary gear mechanism 18. On the outer periphery of the planetary gear mechanism 18, an internal gear 22 meshing with the planetary gear 20 is arranged.

[0032] The internal gear 22 is press-fitted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com