Auxiliary Control System and Method Based on MCU Standing Slope and Half Slope Start

An auxiliary control system and auxiliary control technology, applied in the direction of control drive, control device, power management, etc., can solve the problems of uncertain command torque, large hardware loss, and increased hardware cost, so as to avoid over-temperature damage and improve accuracy High, real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

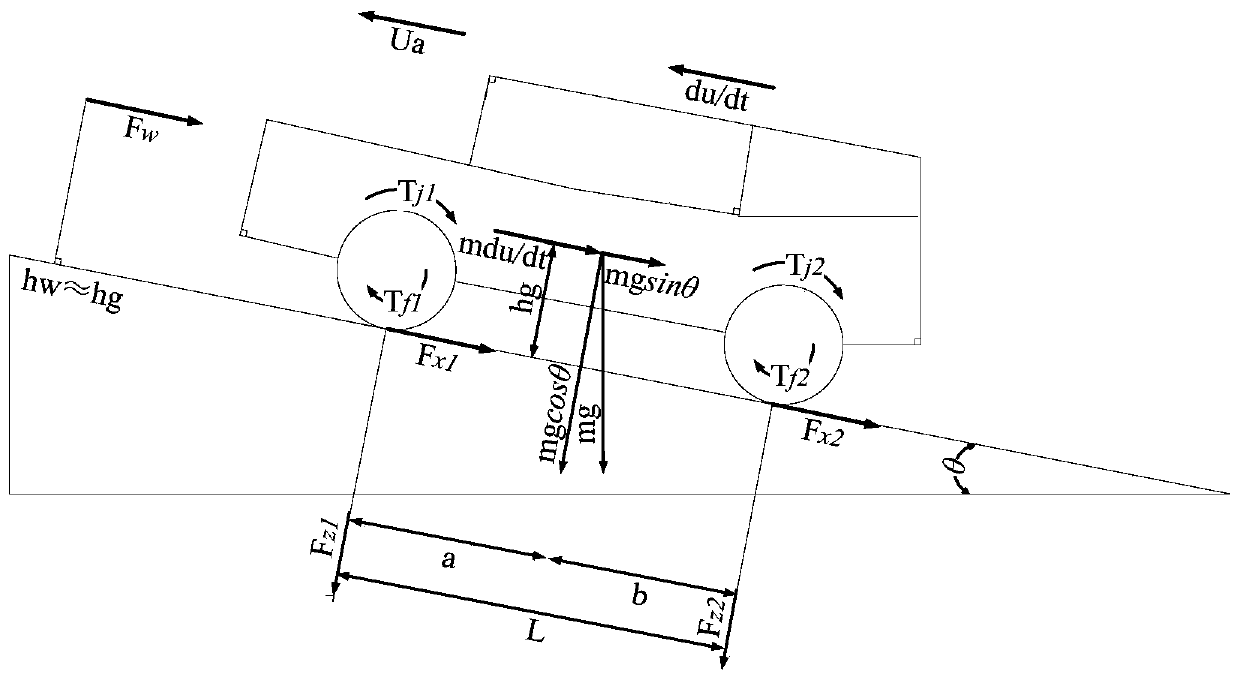

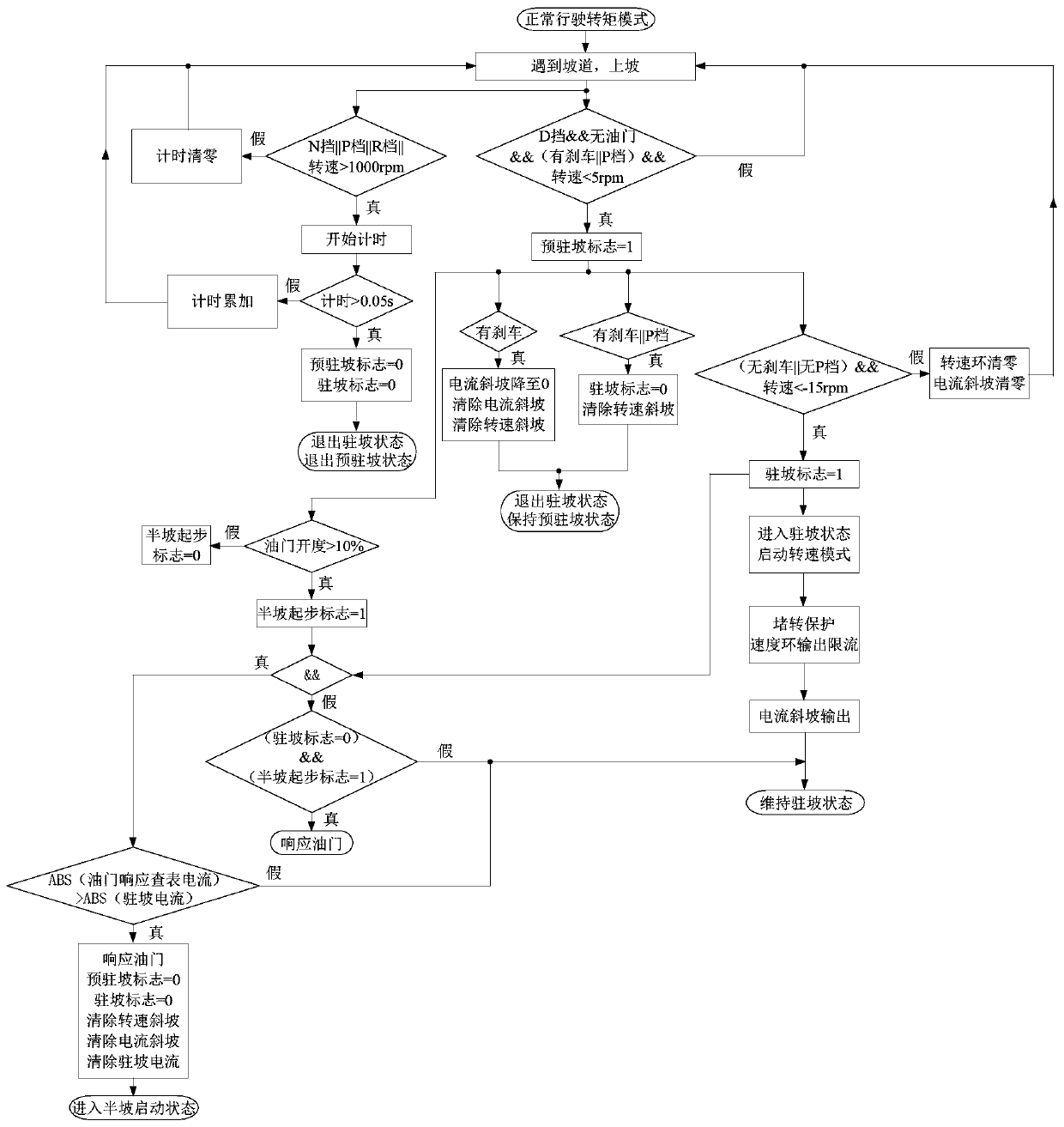

[0047] The MCU-based auxiliary control system for parking on a slope and starting on a half-slope is implemented based on the MCU, and divides the working states of the electric vehicle on the slope, and makes the electric vehicle work in a preset working state. The working state includes the pre-slope state and the exit-slope state, and the MCU gates the pre-slope state and the exit-slope state according to the current vehicle driving state information detected by it, and controls the electric motor The vehicle enters the pre-slope state or exits the state of the slope; the state of the pre-slope includes three sub-states, which are the state of the slope, the state of exiting the standing wave and the state of the pre-slope and the half-slope start state, wherein The electric vehicle has the same working state when exiting the parking slope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com