Irregular superconducting magnet coil winding control device and method

A technology of superconducting magnets and control methods, which is applied in coil manufacturing, inductance/transformer/magnet manufacturing, electric speed/acceleration control, etc. It can solve the problem of large tension error, low tension control accuracy, and inability to meet the requirements of magnet coil winding. To achieve the effect of high torque control precision and constant tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention mainly aims at the particularity of the superconducting magnet coil winding process and the defects and deficiencies of the existing winding control device, and provides an irregular superconducting magnet coil winding control device, which can be used for various materials and coils of different shapes. Winding to achieve constant cable tension and consistent coil tightness during irregular coil winding.

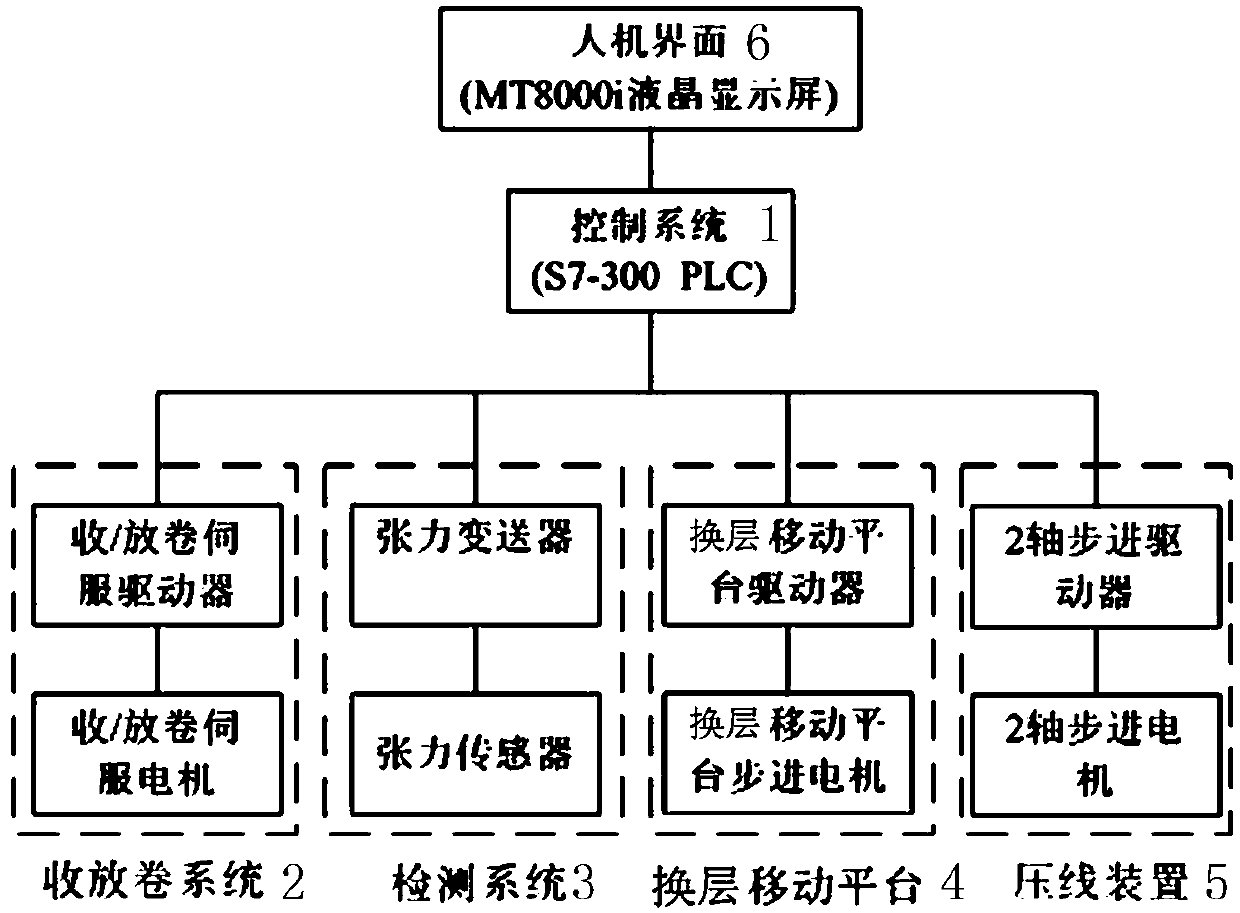

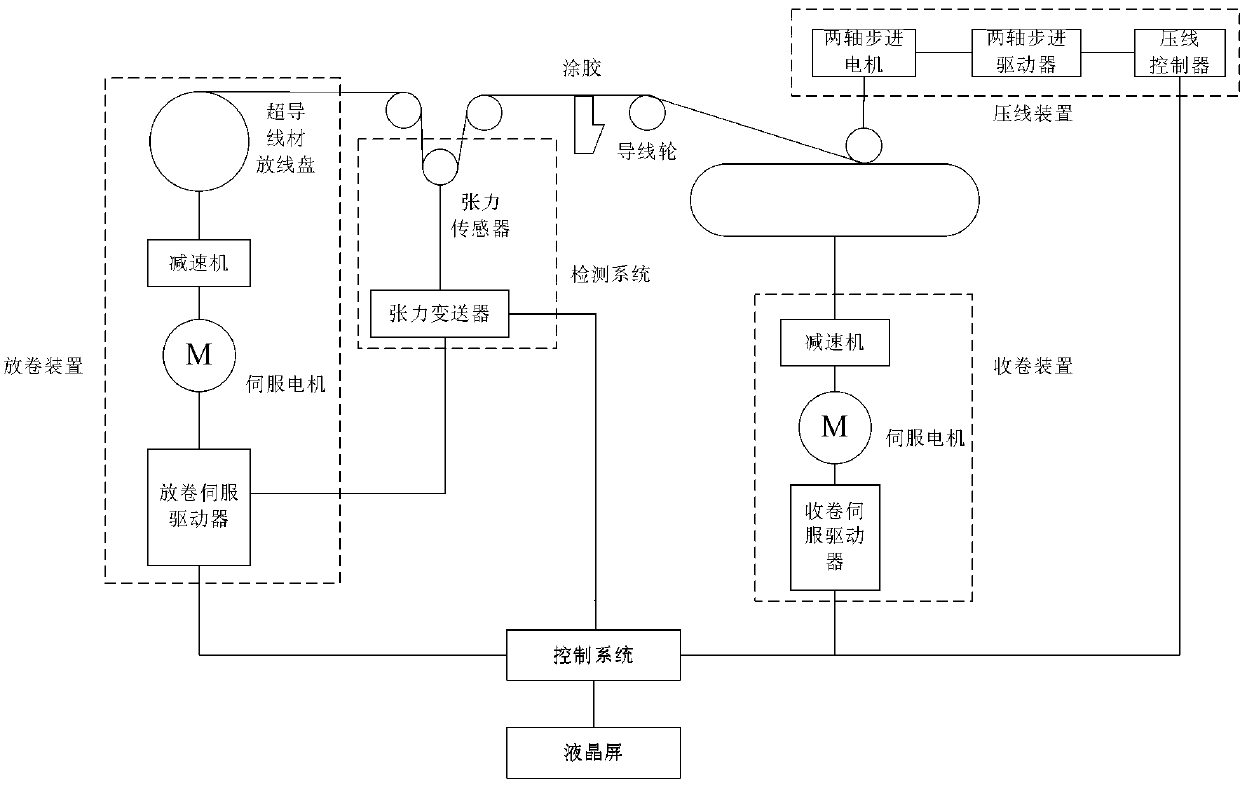

[0029] Such as figure 1 and figure 2 As shown, the winding control device includes a control system 1 and a winding and unwinding system 2 connected to the control system 1 , a detection system 3 , a layer-changing mobile platform 4 and a crimping device 5 .

[0030] Wherein said control system 1, as the control core of the winding device, is mainly responsible for functions such as numerical calculation and the realization of the constant tension control algorithm, completes the numerical calculation and the realization of the constant tensio...

Embodiment 2

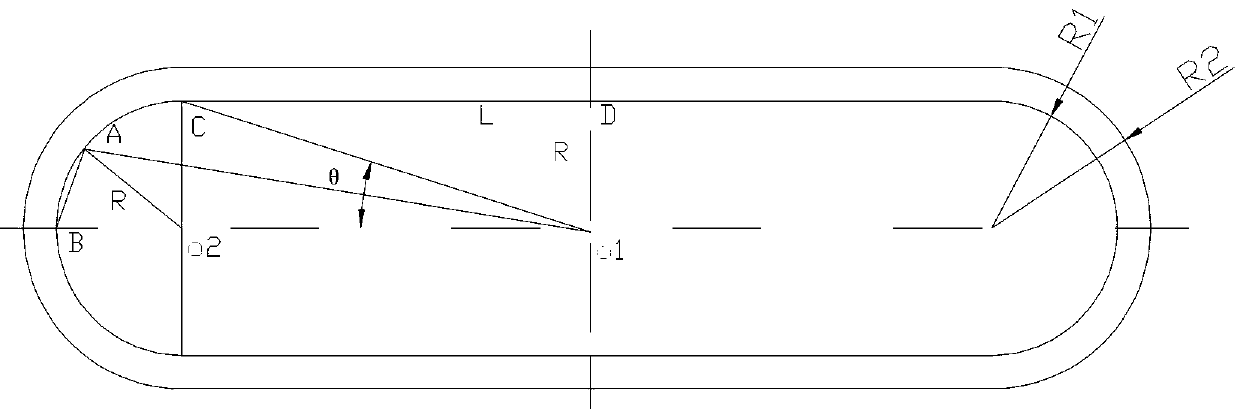

[0039] The following uses the racetrack-type superconducting magnet coil winding control method as an embodiment, and in combination with the attached image 3 , the technical solution of the present invention will be further specifically described. Due to the particularity of the superconducting wire, in order to improve the success rate of superconducting magnet coil winding, it is necessary to control the wire tension and coil bonding tightness during the superconducting coil winding process.

[0040] Wire tension is caused by the deformation of the wire caused by the speed difference between unwinding and rewinding during coil winding. According to Hooke's law, the tension is:

[0041]

[0042] In the formula, V 1 is the unwinding speed, V 2 is the winding speed, K T is the elastic coefficient of the wire.

[0043] According to formula (1), it can be known that to maintain the unwinding speed V 1 Constant, by adjusting the winding speed V 2 Tension control can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com