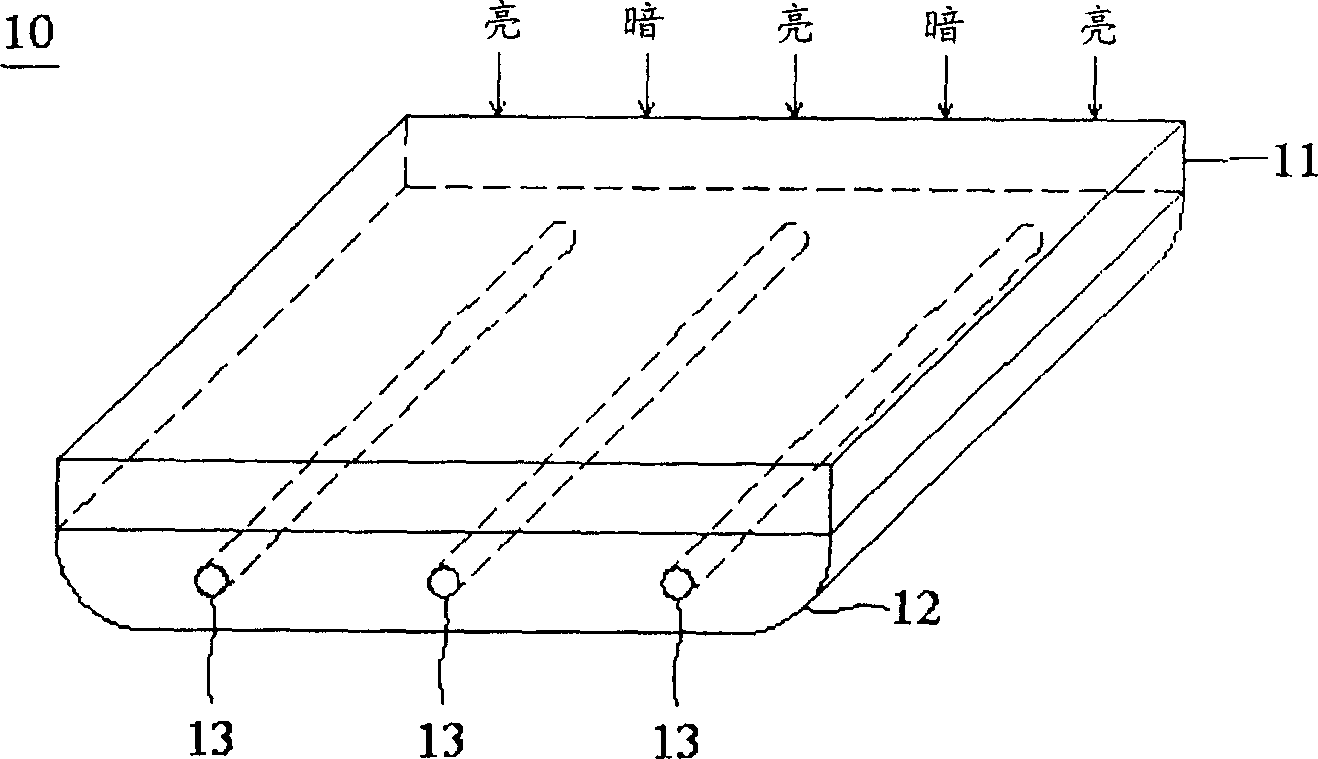

Direct downward background module

A backlight module, direct type technology, applied in the direction of optics, nonlinear optics, instruments, etc., to achieve the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

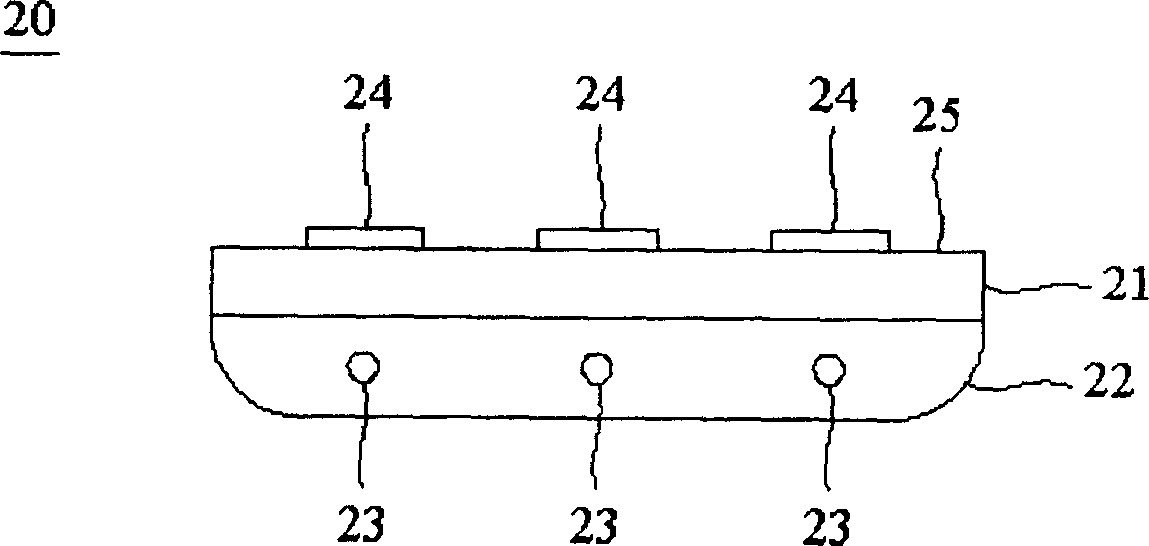

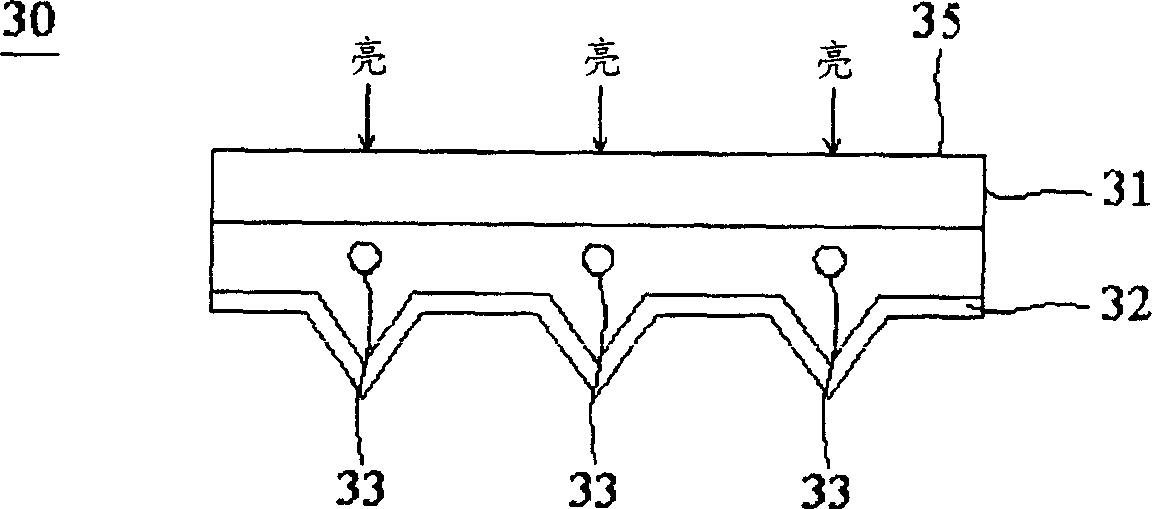

[0015] Please refer to figure 2 , which is a sectional view of the direct-lit backlight module according to the first embodiment of the present invention. In this embodiment, the direct type backlight module 100 has a light guide plate 131 , a reflector 132 and a plurality of light sources 133 , wherein the light sources 133 may be lamp tubes.

[0016] The light guide plate 131 has a light incident surface 134 and a light exit surface 135 , and the light exit surface 135 is located above the light incident surface 134 . The light incident surface 134 has a groove-shaped non-planar structure. The reflection sheet 132 is used for reflecting light. A plurality of light sources 133 are arranged between the light guide plate 131 and the reflection sheet 132; and the plurality of grooves 137 on the light guide plate 131 are arranged corresponding to the positions of the light sources 133, and each light source 133 is placed in a groove 137, which can reduce the number of backligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com