Fluid jetting device

A fluid and ejection port technology is applied in the field of fluid ejection devices to achieve the effect of wear inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

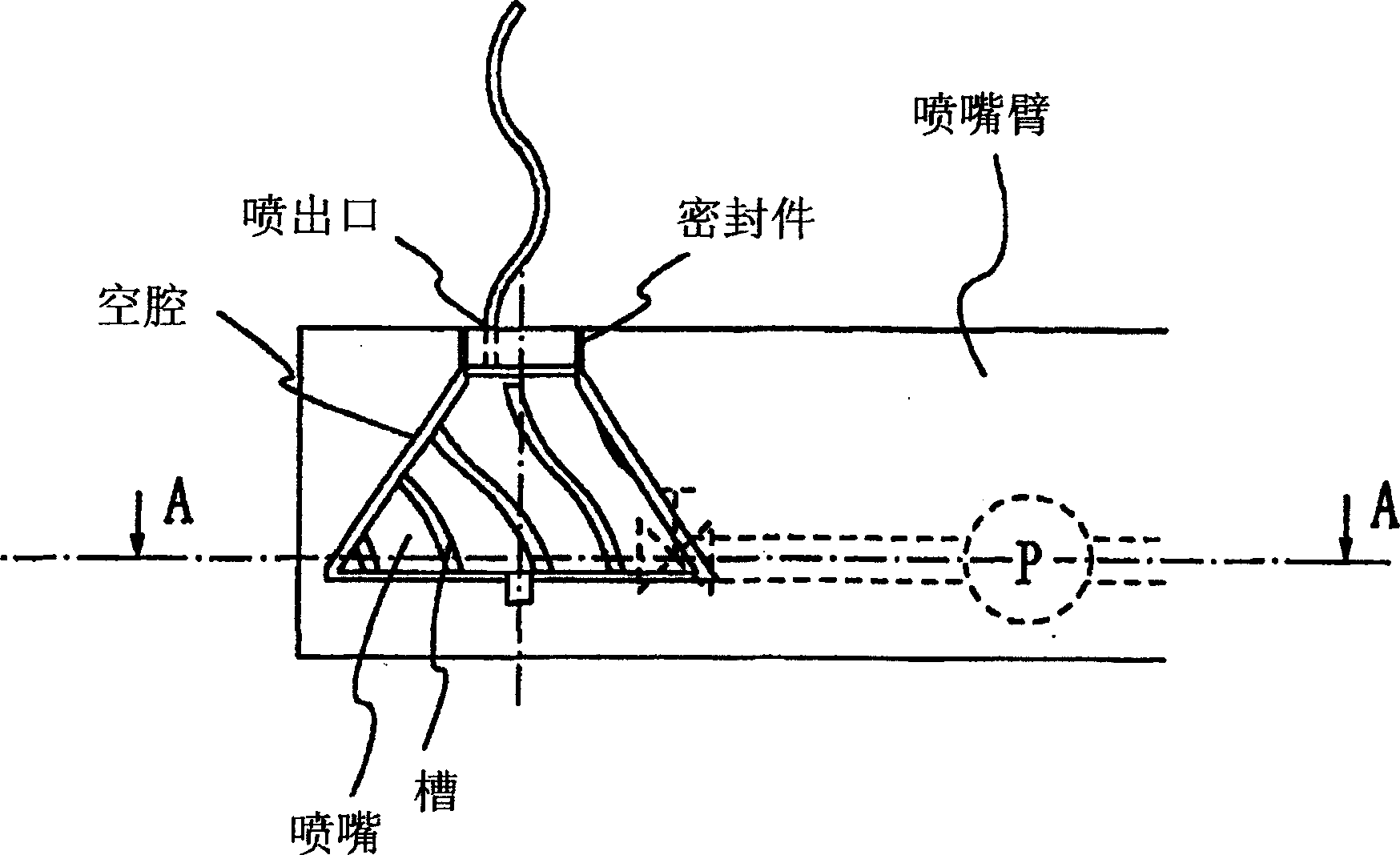

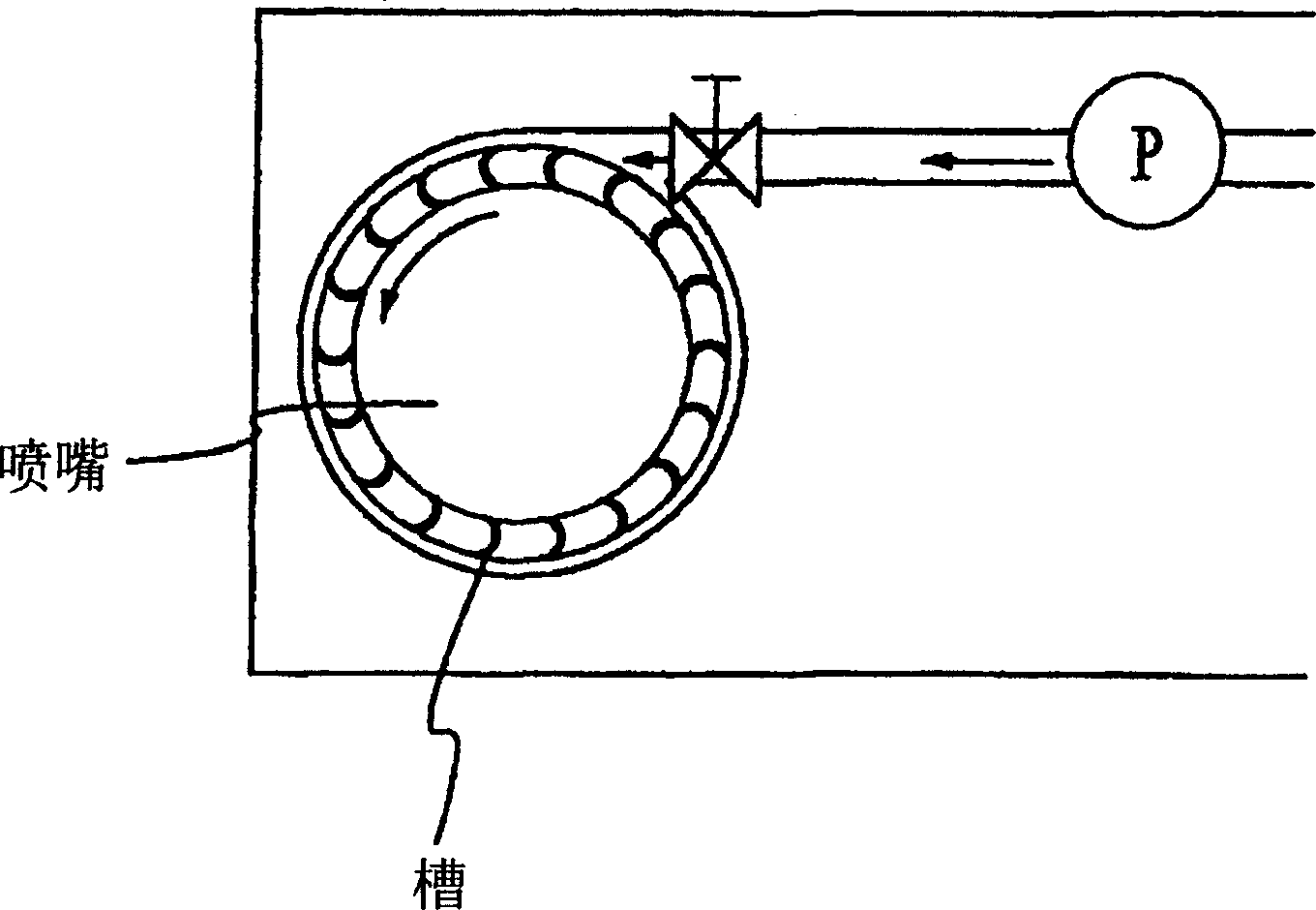

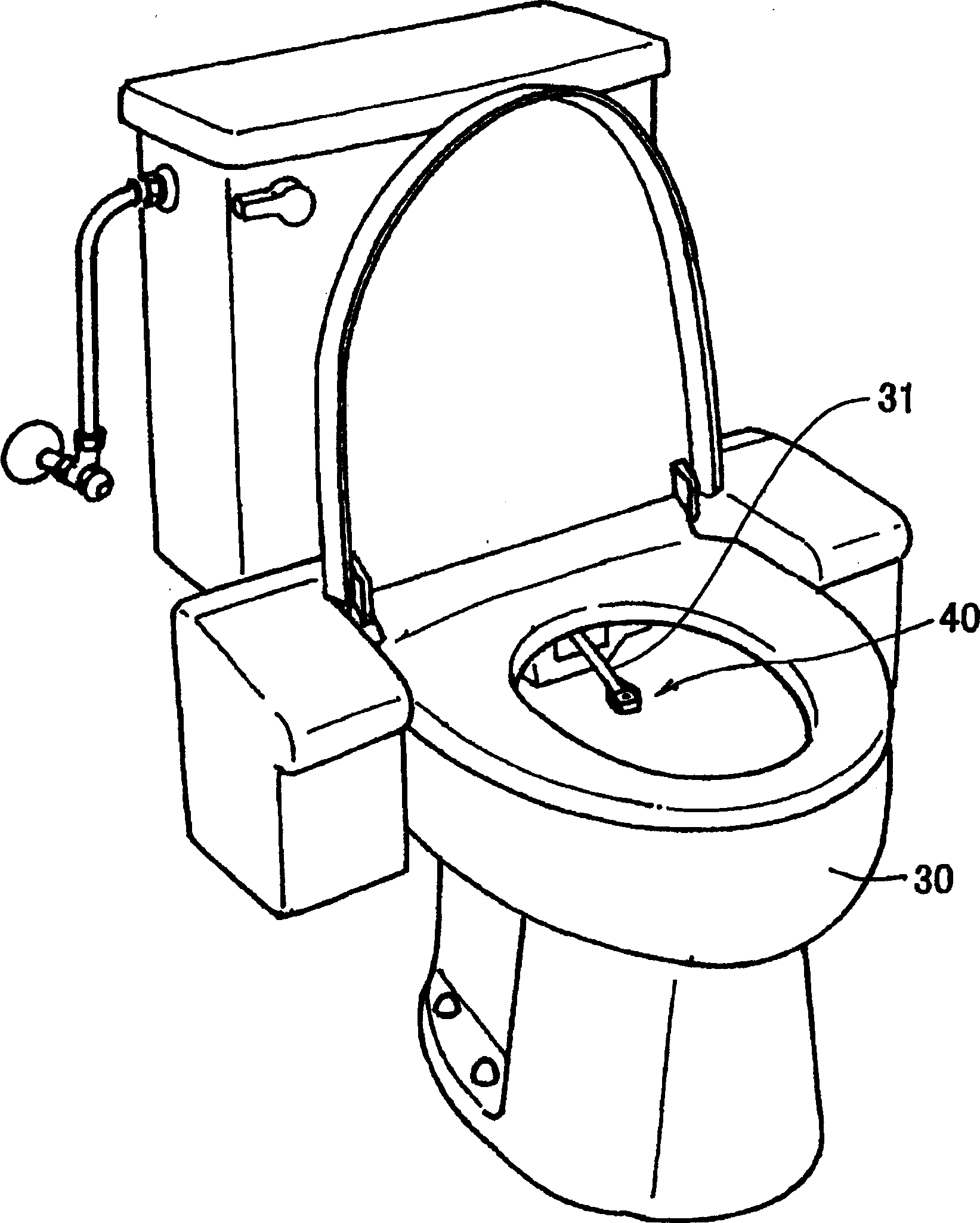

[0101] Next, embodiments of the present invention will be described based on examples. figure 2 is a schematic perspective view of the appearance of a flush toilet 30 having a flushing water spray device 40 according to an embodiment of the present invention, image 3 It is a schematic cross-sectional view in the vertical direction of the cleaning water spraying device 40 according to an embodiment of the present invention and an enlarged explanatory view of important parts thereof, Figure 4 It is a schematic cross-sectional view in the horizontal direction of this washing water spraying device 40 .

[0102] This cleansing water spraying device 40 is suitable for a human body part washing device for washing a part of a human body (such as anus, etc.) after defecation, and is provided in the nozzle arm 31 . The nozzle arm 31 is freely movable forward and backward relative to the toilet bowl, and when washing a part of the body, moves forward to a washing position as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com