Fault detecting panel of high speed wire rolling mill gearbox

A high-speed wire rod and fault detection technology, applied in metal rolling and other directions, to achieve the effect of improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

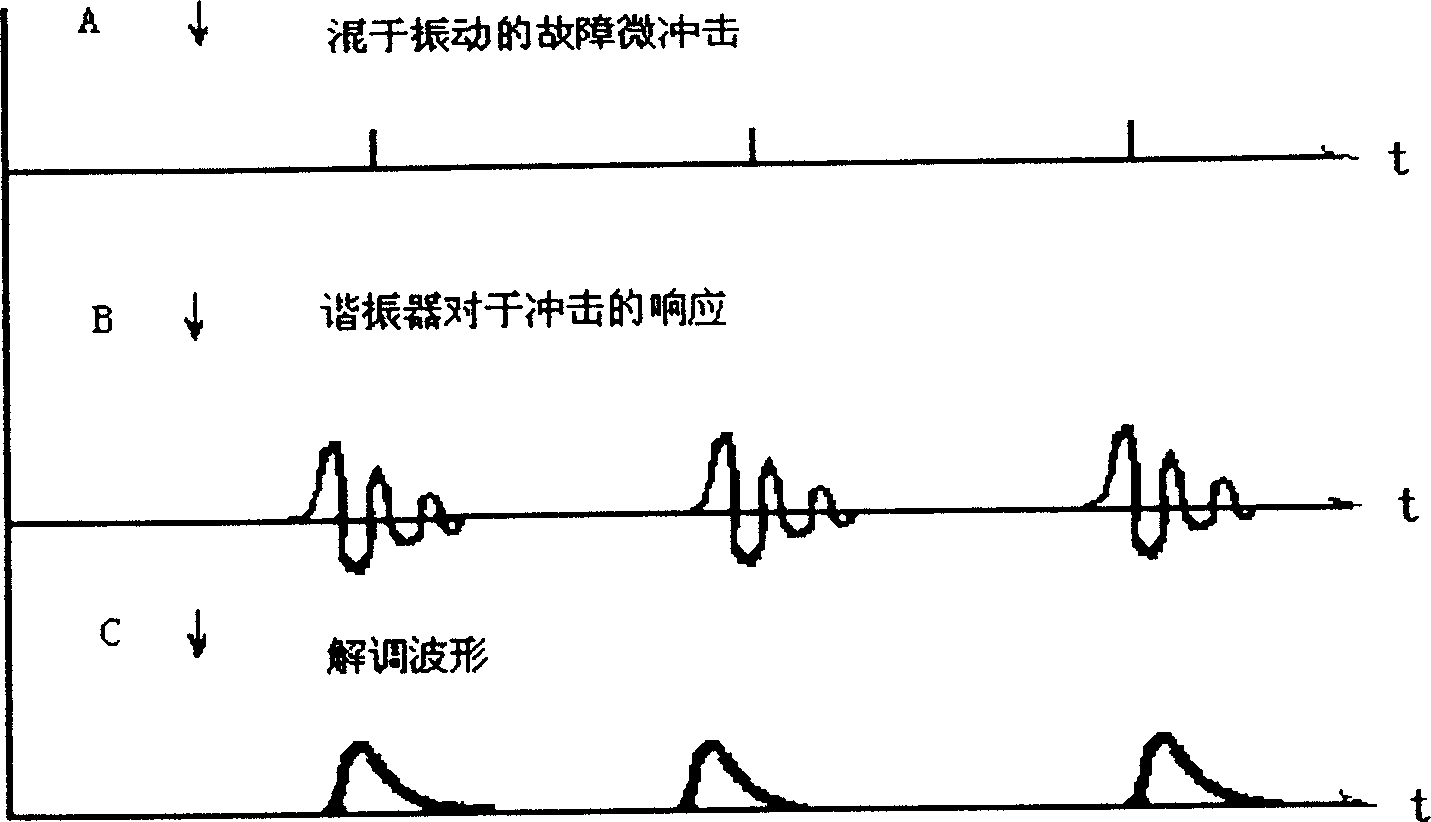

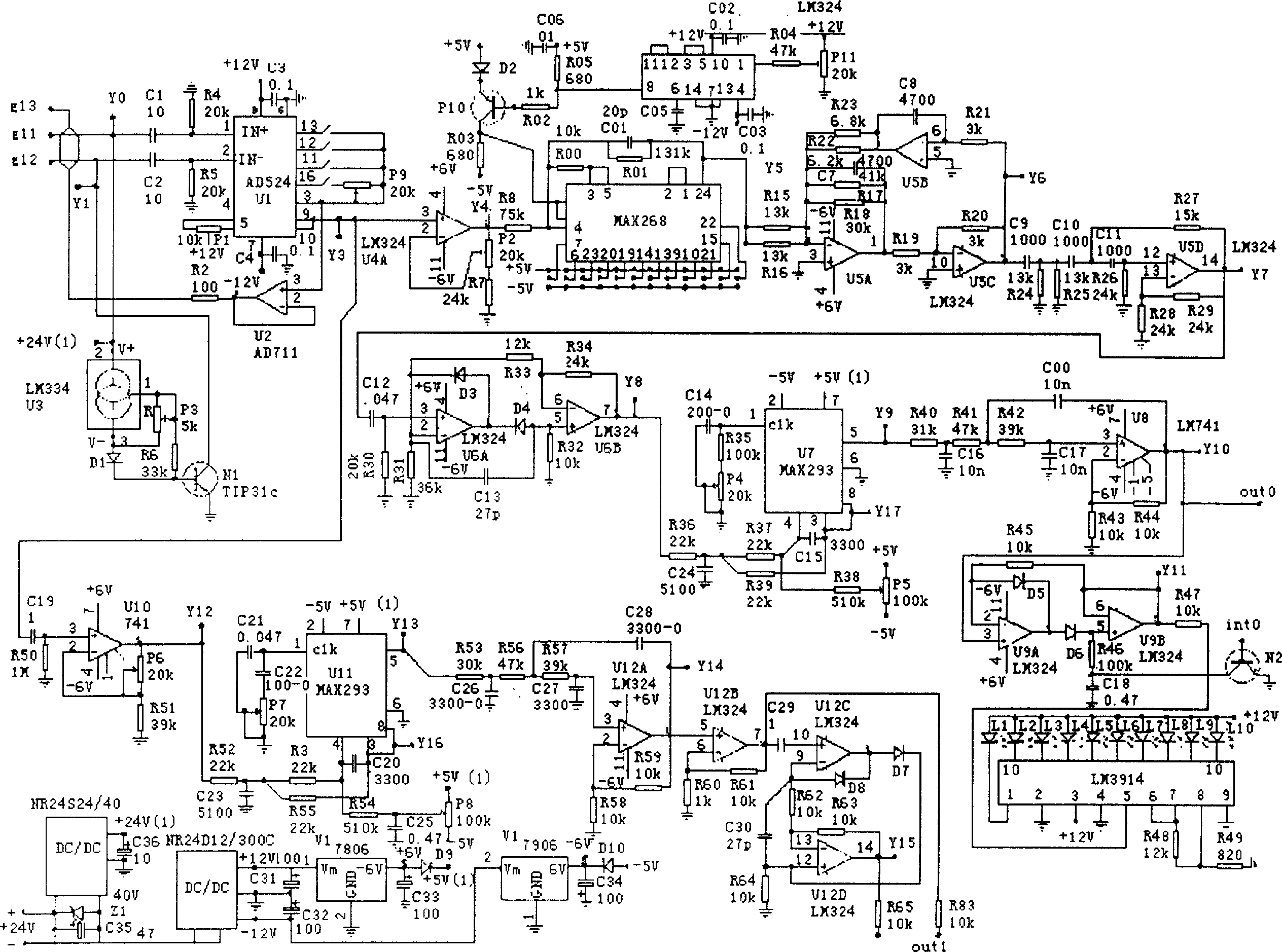

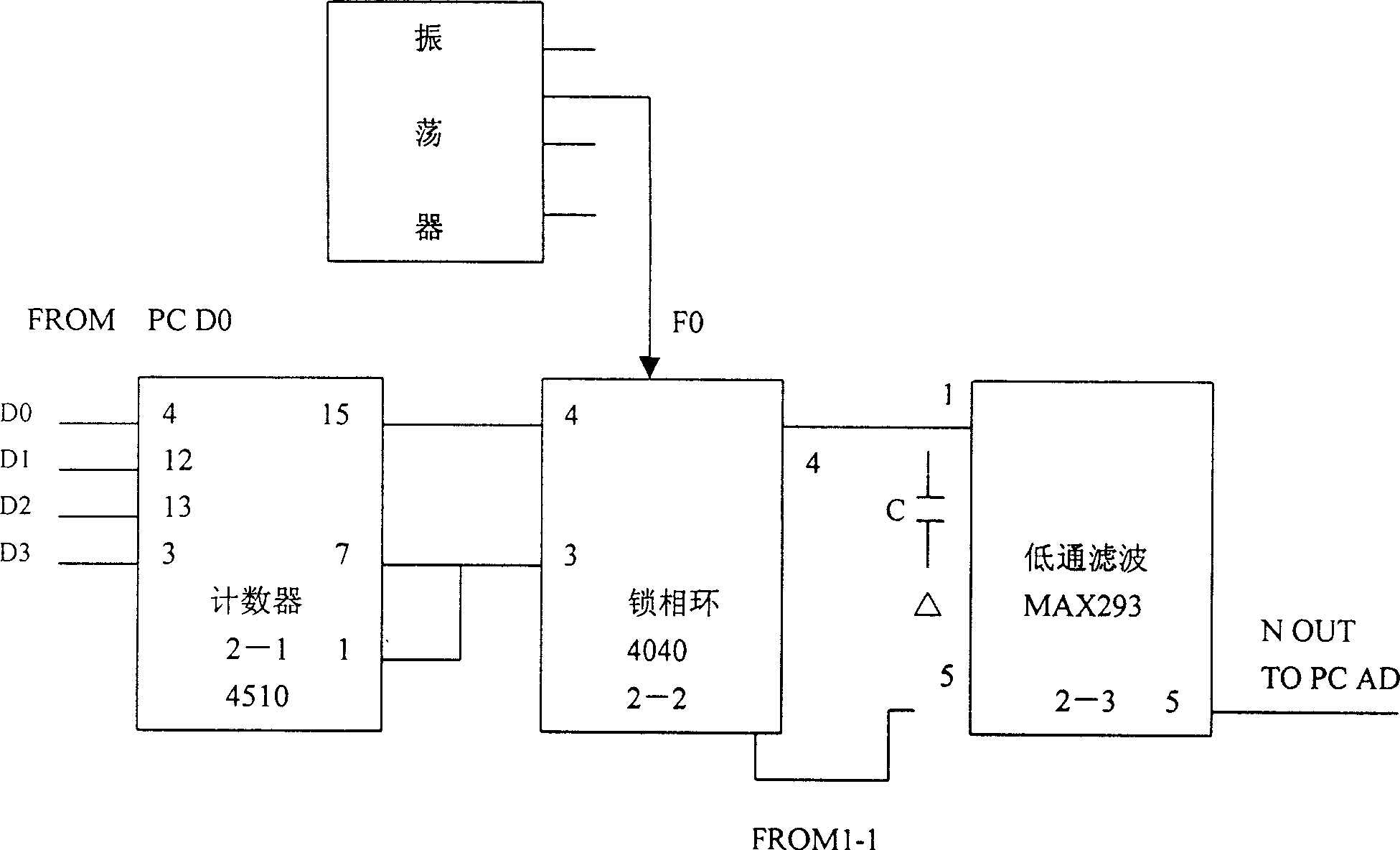

Method used

Image

Examples

Embodiment Construction

[0020] In the present invention, the signal processor is connected to the 0.4mA constant current source vibration signal supplied by the ICP sensor, and the AC vibration signal separated by the signal processor is sent to the demodulation conversion and low-frequency vibration separator respectively, and the demodulation converter then The demodulation signal reflecting the fault impact information is converted from the AC vibration signal, and the low-frequency vibration separator separates the low-frequency vibration signal corresponding to the rotational speed. All processed signals are output to the computer AD interface for external sampling and analysis and diagnosis.

[0021] The low-frequency vibration signal separator is a low-pass filter with a frequency band 1.2-1.5 times the rotational speed frequency fn, which filters vibration signals corresponding to the rotational speed frequency of the rotating body and sends them to the AD interface of an external computer for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com