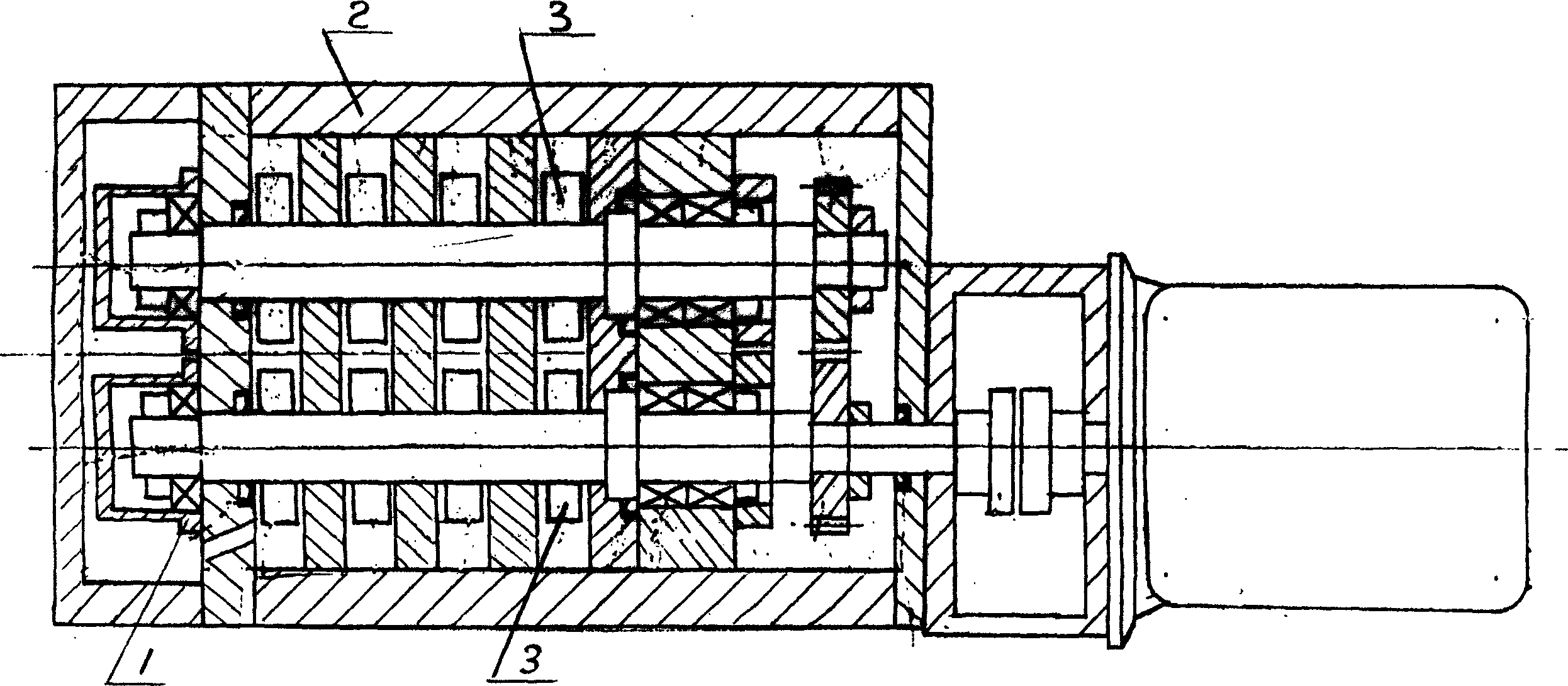

Involute and straight claw type rotor structure for oilless vacuum pump

An oil-free vacuum pump and rotor structure technology, applied in the involute field, can solve the problems of high vibration and noise, short service life, complicated processing technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

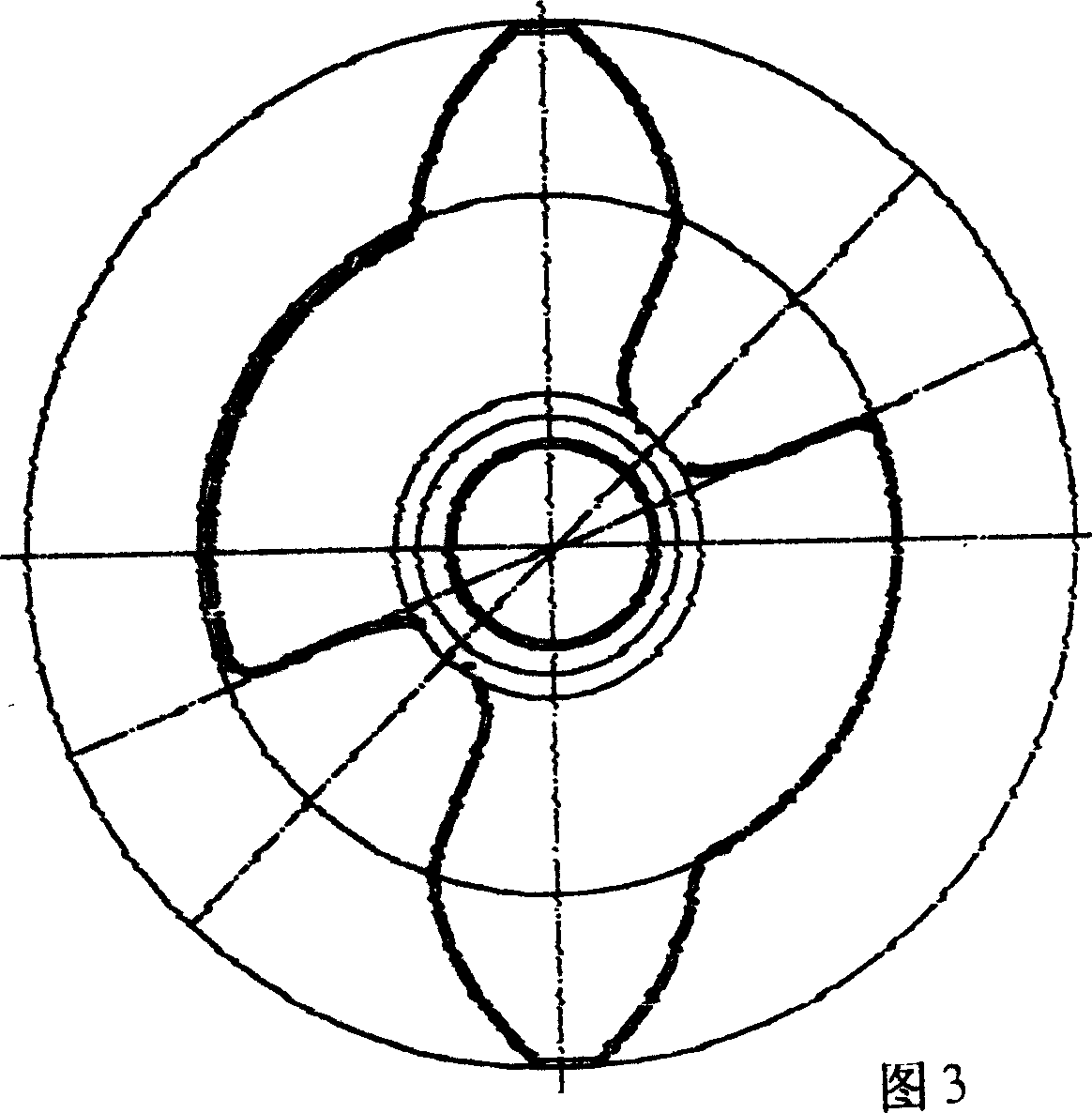

Embodiment approach

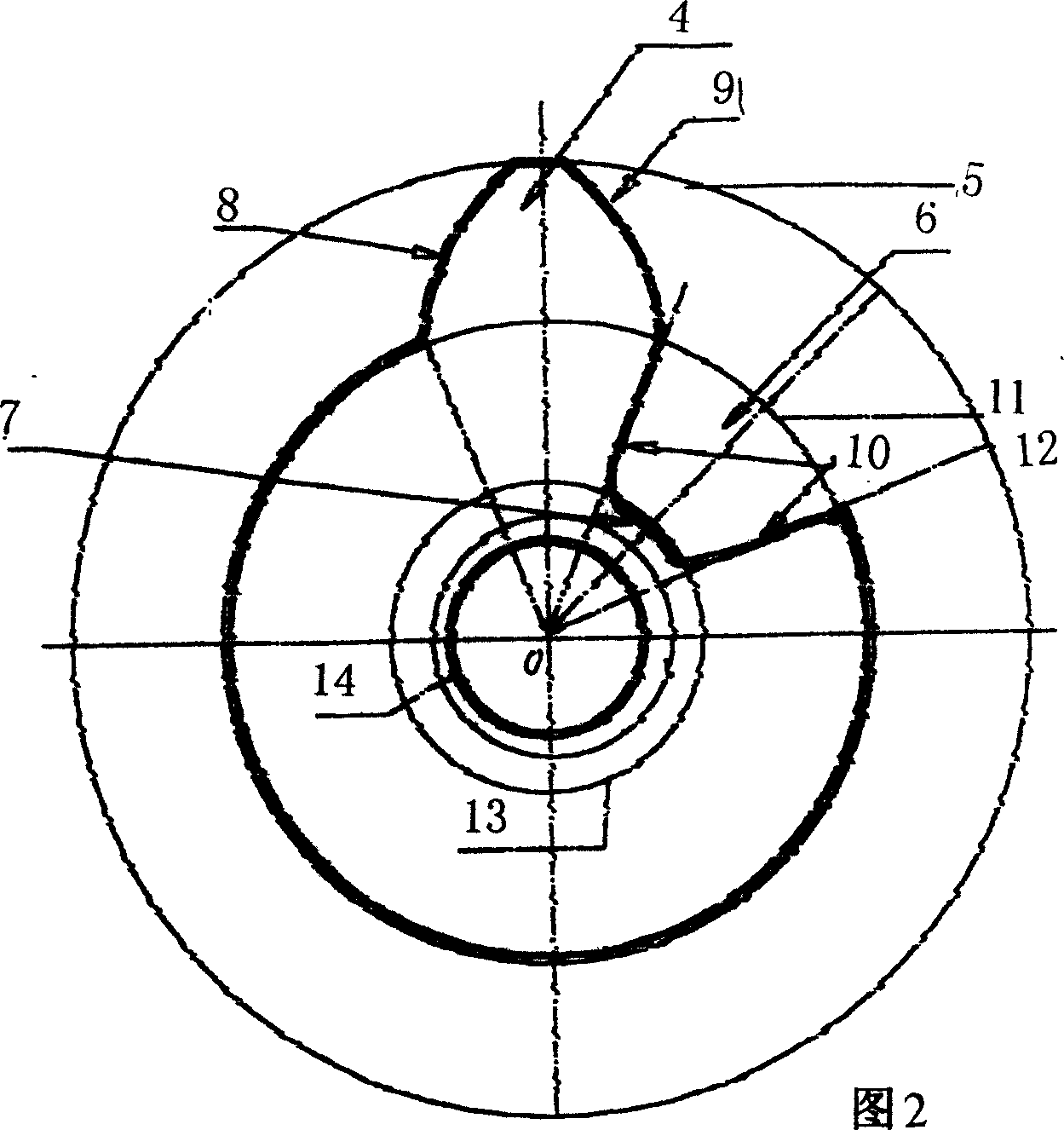

[0032] 1. The design of the rotor claw shape

[0033] 1), digital point diagram method: use the mature gear involute design theory, select the appropriate calculation formula as follows:

[0034]

[0035]

[0036] In the formula: ro is the radius of the base circle; βi is the tangent line made by any point on the involute line to the system circle, and the angle between the radius of the tangent point and the OX axis; The radius of MO is the angle between the radius OA′ and the OX axis when turning 20° counterclockwise; βi′=βo-βi; is the radian value of βi′; Δβ is an increment, which is the increment of βi′ from 0 as the involute AB gradually expands from point A, and the angle increment is artificially selected for each drawing to obtain the value of βi′.

[0037] n

βi'=nΔβ

Spend

22.5-βi′

Spend

Xi

Yi

Remark

0

20

2.5

11.79

29.58

Involute starting point A

5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com