Air cleaner

An air filter and filter technology, which is applied in combustion air/combustion-air treatment, machine/engine, bicycle accessories, etc., can solve the problems of unsatisfactory resource utilization, increased economic burden on users, and many waste parts. , to achieve the effect of reducing replacement costs, easy assembly, and easy shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described below according to the embodiments of the present invention shown in the accompanying drawings.

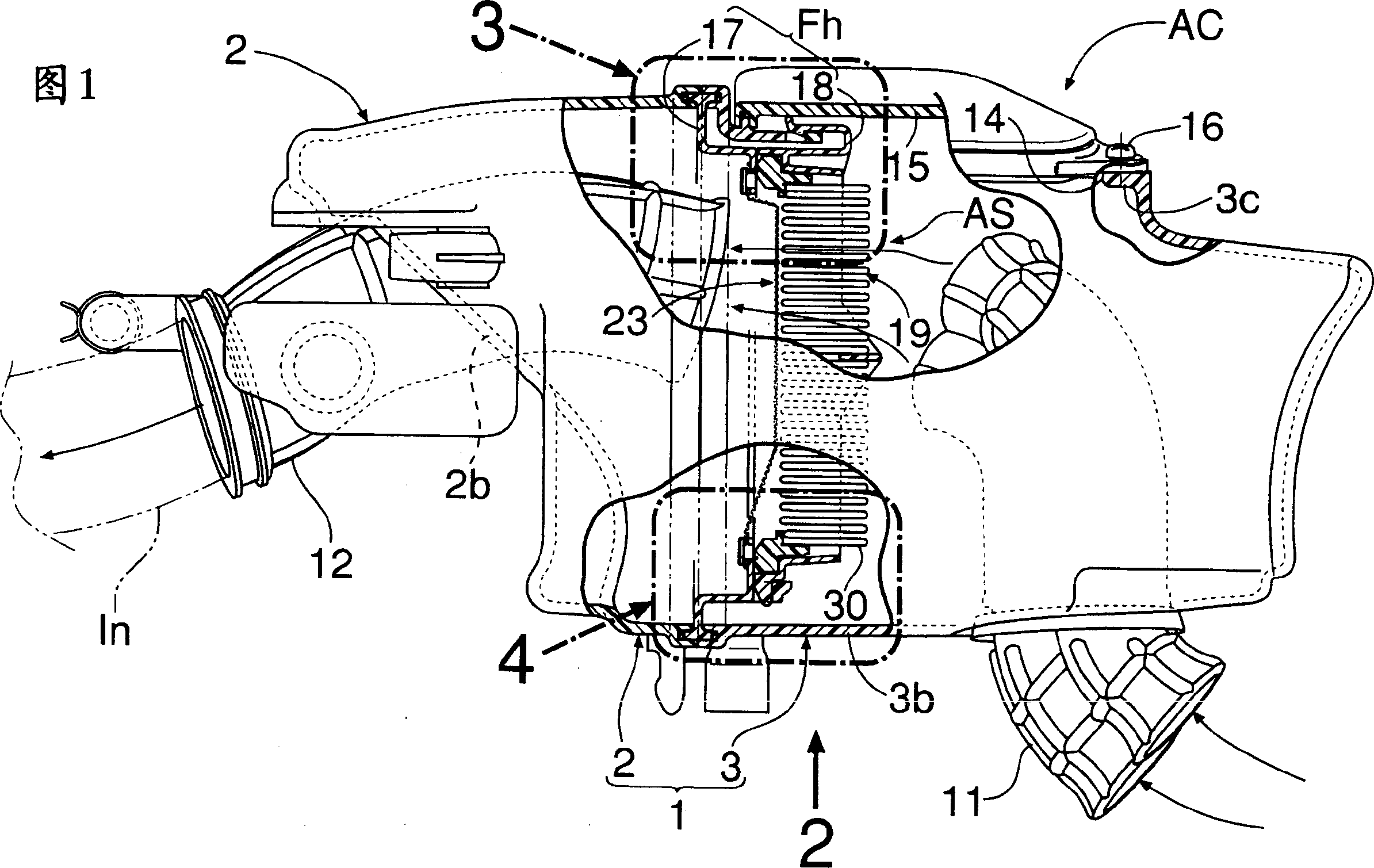

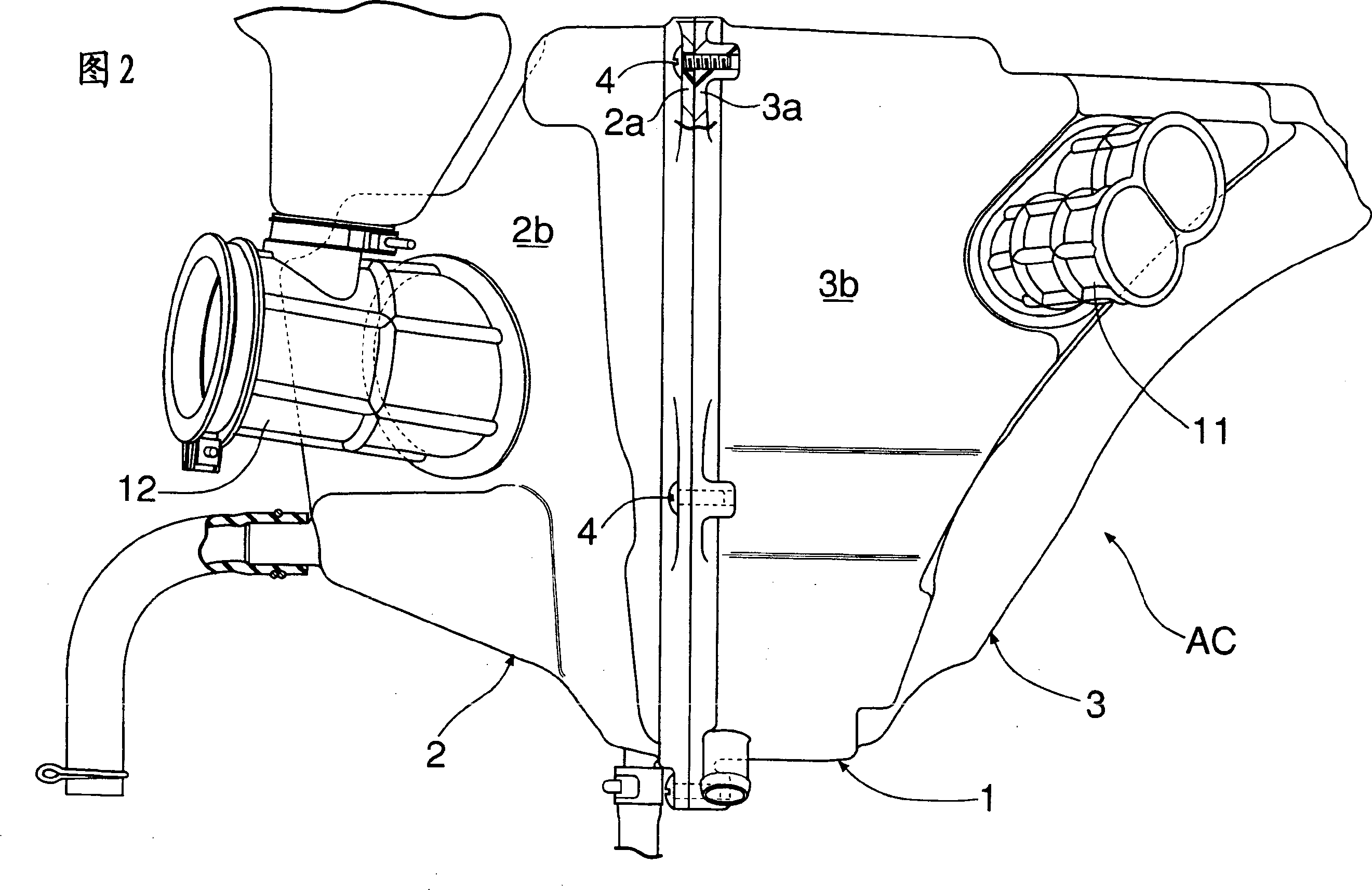

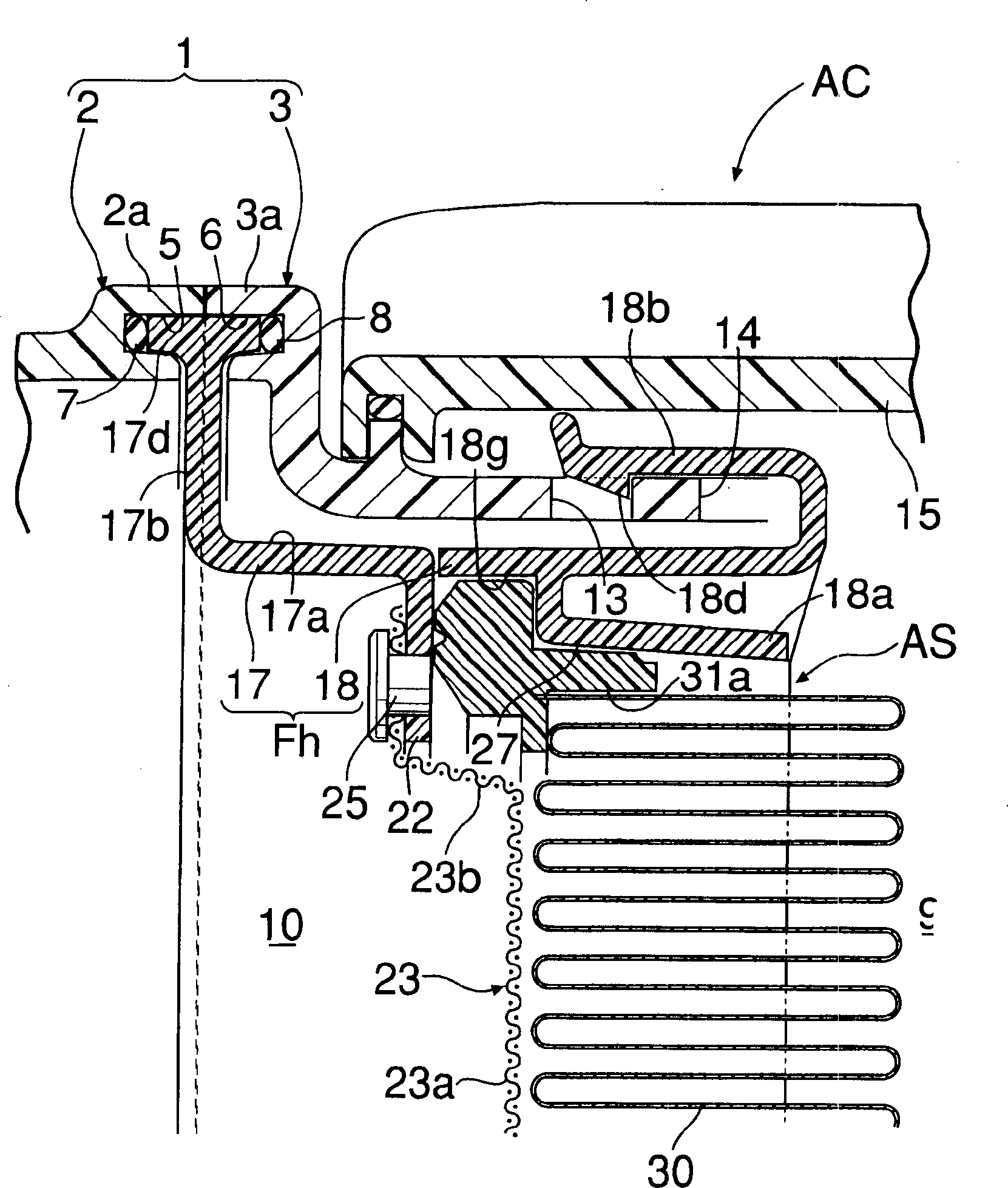

[0021] In Fig. 1 and Fig. 2, the filter case 1 of the air cleaner Ac is made of hard synthetic resin, and is divided into a case body 2 and a cover body 3, and their split opening end faces are butted together, and there are many A small screw 4 joins outward flanges 2a, 3a formed on their peripheries into one body and forms a closed shape. On the split opening end faces of the housing body 2 and the cover body 3, annular fitting grooves 5, 6 that are consistent with each other are respectively formed, and in these fitting grooves 5, 6, through packings 7, 8, the airtight The outer edge portion ( image 3 ).

[0022] In the filter housing 1, the filter element assembly AS described in detail later is kept between the connection part of the housing body 2 and the cover body 3, and the filter housing is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com